No products

Product successfully added to your cart

0 products in the cart 1 product in the cart

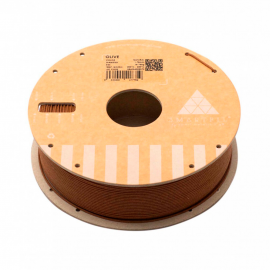

In the cosplay world the three most coveted properties of any material used for the preparation of accessories are sandability, paintability, and durability. Polymaker has managed to develop a filament that can satisfy all these needs - the PolyLite CosPLA filament. This filament is a specialized PLA variant meticulously engineered for crafting cosplay props with precision and resilience.

Image 1: Unprocessed part 3D printed with the CosPLA filament. Source: Polymaker.

Designed to meet the demands of cosplay enthusiasts, this filament boasts enhanced properties tailored for seamless post-processing, heightened durability, and effortless paint application, thus significantly outperforming standard PLA. The PolyLite CosPLA filament is available in two distinct formulations, CosPLA A and B. Although both are tough and post-processable, each variant is slightly tweaked to cater to specific cosplay needs.

Image 2: The properties of CosPLA compared to standard PLA, PETG and ABS. Source: Polymaker.

CosPLA A excels in sanding capabilities, facilitating swift refinement of intricate details and complex structures such as helmets and fine components. On the other hand, CosPLA B prioritizes robustness, making it the go-to choice for crafting formidable props like swords, hammers, and armor, which may encounter impact or require additional strength. Both versions of CosPLA share a common trait of exceptional sandability, paintability, and durability, ensuring consistency in performance across diverse cosplay projects.

Image 3: Different levels of post-processing on a mask 3D printed with CosPLA by preciselykay. Source: Polymaker.

However, for applications necessitating heat and weather resistance alongside post-processing ease and impact resilience, Polymaker recommends exploring alternatives such as PolyLite ABS for superior heat resistance and PolyLite ASA for unparalleled weather and UV protection. Like CosPLA, these alternatives offer remarkable post-processing ease while addressing specific environmental challenges, with PolyLite ABS excelling in hot environments and PolyLite ASA proving ideal for outdoor use.

| Elongation at break (%) | 4 |

| Tensile strength (MPa) | 40 |

| Tensile modulus (MPa) | 2600 |

| Flexural strength (MPa) | 68 |

| Flexural modulus (MPa) | 2700 |

| Softening temperature (ºC) | 62 |

| Machinable | Machinable |

| Hide color variations | (Hide color variations) |