No products

Product successfully added to your cart

0 products in the cart 1 product in the cart

Copolyesters (PET)

There are 45 products.Copolyester filaments (PET, PETG, CPE...) are able to withstand high tensile stresses and exhibit high durability and chemical resistance, as well as excellent inter-layer adhesion.

-

PETG Filalab PETG Filalab

17,99 € tax excl.

17,99 € tax incl.Durable and robust PETG ideal for the 3D printing of functional parts. Durable and robust PETG ideal for the 3D printing of functional parts.

-

PETG - R3D PETG - R3D

16,99 € tax excl.

16,99 € tax incl.Easy to print PETG filament for tough parts with good chemical resistance. Easy to print PETG filament for tough parts with good chemical resistance.

-

Fiberlogy Easy PETG Fiberlogy Easy PETG

18,40 € tax excl.

18,40 € tax incl.High quality PETG filament with excellent mechanical and aesthetic properties. High quality PETG filament with excellent mechanical and aesthetic properties.

-

ReFill PETG Standard HS - Rosa3D ReFill PETG Standard HS - Rosa3D

12,75 € tax excl.

12,75 € tax incl.Food-safe PETG filament with chemical resistance. Many vibrant colors, also translucid. Food-safe PETG filament with chemical resistance. Many vibrant colors, also translucid.

-

Smartfil PETG Smartfil PETG

20,35 € tax excl.

20,35 € tax incl.Thermoplastic copolyester that stands out for its great chemical resistance, hardness and transparency. Thermoplastic copolyester that stands out for its great chemical resistance, hardness and transparency.

-

PETG - Jamg He PETG - Jamg He

15,66 € tax excl.

15,66 € tax incl.PETG filament for tough and resistant glossy 3D parts with no warping. PETG filament for tough and resistant glossy 3D parts with no warping.

-

CPE HG100 (Advanced PETG) CPE HG100 (Advanced PETG)

29,30 € tax excl.

29,30 € tax incl.Chlorinated Polyethylene that stands out for its application in containers that are in contact with food. Chlorinated Polyethylene that stands out for its application in containers that are in contact with food.

-

CPE CF112 Carbon CPE CF112 Carbon

44,21 € tax excl.

44,21 € tax incl.Filament reinforced with carbon fiber that stands out for its resistance to wear and its great hardness. Filament reinforced with carbon fiber that stands out for its resistance to wear and its great hardness.

-

Fiberlogy Refill Easy PETG Fiberlogy Refill Easy PETG

16,45 € tax excl.

16,45 € tax incl.High quality PETG filament in masterspool format. High quality PETG filament in masterspool format.

-

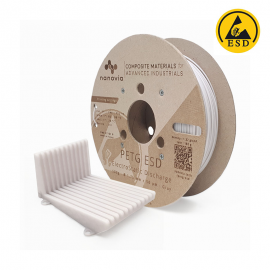

3DXSTAT ESD PETG 3DXSTAT ESD PETG

110,00 € tax excl.

110,00 € tax incl.PETG filament developed for applications requiring protection against electrostatic discharge. PETG filament developed for applications requiring protection against electrostatic discharge.

-

Fiberlogy PCTG Fiberlogy PCTG

25,25 € tax excl.

25,25 € tax incl.Impact and heat resistant PCTG available in many attractive colors. Impact and heat resistant PCTG available in many attractive colors.

-

PolyMax Tough PETG PolyMax Tough PETG

44,95 € tax excl.

44,95 € tax incl.Industrial material with high flexibility and chemical resistance for final parts and functional prototypes. Industrial material with high flexibility and chemical resistance for final parts and functional prototypes.

-

PolyLite PETG PolyLite PETG

29,95 € tax excl.

29,95 € tax incl.Highly flexible and chemically resistant material, suitable for final parts and functional prototypes. Highly flexible and chemically resistant material, suitable for final parts and functional prototypes.

-

PETG Premium Raise3D PETG Premium Raise3D

29,99 € tax excl.

29,99 € tax incl.High quality PETG filament, tested for optimal 3D printing with Raise 3D printers. High quality PETG filament, tested for optimal 3D printing with Raise 3D printers.

-

Taulman T-Glase (PETT) Taulman T-Glase (PETT)

41,95 € tax excl.

41,95 € tax incl.Innovative filament PETT by Taulman, stands out for its high transparency and resistance. Innovative filament PETT by Taulman, stands out for its high transparency and resistance.

-

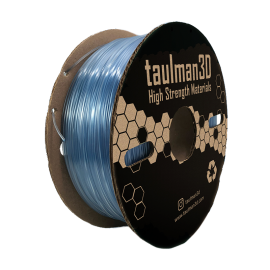

Taulman TECH-G (PETG) Taulman TECH-G (PETG)

44,95 € tax excl.

44,95 € tax incl.This is a technical material, developed for realization of functional prototypes. This is a technical material, developed for realization of functional prototypes.

-

Taulman T-lyne Taulman T-lyne

44,45 € tax excl.

44,45 € tax incl.Copolyester (PET) that stands out for its flexibility, durability and its glass finish. Copolyester (PET) that stands out for its flexibility, durability and its glass finish.

-

Taulman Guidel!ne (PETG) Taulman Guidel!ne (PETG)

56,95 € tax excl.

56,95 € tax incl.PETG ideal for printing small details, aimed at medical applications and clinical (complies ISO 10993). PETG ideal for printing small details, aimed at medical applications and clinical (complies ISO 10993).

-

PETG ESD Raise3D PETG ESD Raise3D

99,99 € tax excl.

99,99 € tax incl.Industrial ESD safe PETg filament with chemical and heat resistance. Industrial ESD safe PETg filament with chemical and heat resistance.

-

PETG with carbon fiber (PETG CF) PETG with carbon fiber (PETG CF)

40,25 € tax excl.

40,25 € tax incl.All the advantages and ease of printing of PETG with the high mechanical strength of carbon fiber. All the advantages and ease of printing of PETG with the high mechanical strength of carbon fiber.

-

PETG with aramid fiber (PETG AF) PETG with aramid fiber (PETG AF)

5,18 € tax excl.

5,18 € tax incl. 12,95 € -60%All the advantages of PETG combined with the high resistance to impact and friction of aramid fiber. All the advantages of PETG combined with the high resistance to impact and friction of aramid fiber.

Reduced price! -

Rigid X Rigid X

67,75 € tax excl.

67,75 € tax incl.PETG filament with carbon fibre ideal for a wide range of demanding applications. PETG filament with carbon fibre ideal for a wide range of demanding applications.

-

PETG MDT (Magnetically detectable) PETG MDT (Magnetically detectable)

37,10 € tax excl.

37,10 € tax incl.PETG MDT is detected by all types of metal detectors, without being composed of any contaminating element. PETG MDT is detected by all types of metal detectors, without being composed of any contaminating element.

-

Zortrax Z-PETG Zortrax Z-PETG

44,00 € tax excl.

44,00 € tax incl.Glycol PET optimised for Zortrax 3D printers and compatible with any FDM printer. Glycol PET optimised for Zortrax 3D printers and compatible with any FDM printer.

-

Zortrax Z-GLASS Zortrax Z-GLASS

44,00 € tax excl.

44,00 € tax incl.PETG based filament, good properties, chemical resistance and translucent finish. PETG based filament, good properties, chemical resistance and translucent finish.

-

Zortrax Z-ESD V2 Zortrax Z-ESD V2

109,00 € tax excl.

109,00 € tax incl.PET-based filament with a surface resistivity that provides excellent antistatic properties. PET-based filament with a surface resistivity that provides excellent antistatic properties.

-

Smartfil GLACE Smartfil GLACE

32,15 € tax excl.

32,15 € tax incl.Material with good mechanical properties and that allows an almost 100% translucent finish. Material with good mechanical properties and that allows an almost 100% translucent finish.

-

Carbonfil PETG Carbonfil PETG

30,99 € tax excl.

30,99 € tax incl.Much more rigid and resistant PETG filament thanks to the carbon fibre filling. Much more rigid and resistant PETG filament thanks to the carbon fibre filling.

-

Premium PETG Fillamentum Premium PETG Fillamentum

31,46 € tax excl.

31,46 € tax incl.Material of great hardness, flexibility and chemical resistance, suitable for direct contact with food. Material of great hardness, flexibility and chemical resistance, suitable for direct contact with food.

-

Taulman Enviro PETG Taulman Enviro PETG

42,95 € tax excl.

42,95 € tax incl.First 100% recycled PETG in the Taulman3D recycled range. First 100% recycled PETG in the Taulman3D recycled range.

-

Essentium PCTG Essentium PCTG

40,00 € tax excl.

40,00 € tax incl.General use PCTG, great impact strength and chemical resistance. Suitable for biomedicine and manufacturing. General use PCTG, great impact strength and chemical resistance. Suitable for biomedicine and manufacturing.

-

Essentium PET-CF Essentium PET-CF

75,00 € tax excl.

75,00 € tax incl.Strong, stiff and light CF-reinforced PET. Excellent heat, solvent, warping and moisture resistance. Strong, stiff and light CF-reinforced PET. Excellent heat, solvent, warping and moisture resistance.

-

Innovatefil PETG FP Innovatefil PETG FP

37,56 € tax excl.

37,56 € tax incl.Low shrinkage, flame retardant PETG filament ideal for printing tough and soft parts. Low shrinkage, flame retardant PETG filament ideal for printing tough and soft parts.

-

Facilan™ HT Facilan™ HT

35,00 € tax excl.

35,00 € tax incl.High temperature resistant Facilan HT filament with a glossy finish. High temperature resistant Facilan HT filament with a glossy finish.

-

PET Ultrafuse PET Ultrafuse

21,04 € tax excl.

21,04 € tax incl.Food safe PET filament with excellent mechanical properties, good layer adhesion and great finish. Food safe PET filament with excellent mechanical properties, good layer adhesion and great finish.

-

rPET Ultrafuse rPET Ultrafuse

23,51 € tax excl.

23,51 € tax incl.Recycled PET filament with natural transparency, good mechanical properties and great printability. Recycled PET filament with natural transparency, good mechanical properties and great printability.

-

PET CF15 Ultrafuse PET CF15 Ultrafuse

67,14 € tax excl.

67,14 € tax incl.PET CF15 ideal for thermally, chemically and mechanically resistant parts and humid environments. PET CF15 ideal for thermally, chemically and mechanically resistant parts and humid environments.

-

PET CF Raise3D PET CF Raise3D

79,99 € tax excl.

79,99 € tax incl.Rigid and strong industrial PET with 15 % of carbon fibers, thermally and chemically resistant. Rigid and strong industrial PET with 15 % of carbon fibers, thermally and chemically resistant.

-

PET-G MATT Spectrum PET-G MATT Spectrum

30,00 € tax excl.

30,00 € tax incl.Easy to print PETG filament for resistant parts with a matte surface finish. Easy to print PETG filament for resistant parts with a matte surface finish.

-

PETG ESD PETG ESD

47,50 € tax excl.

47,50 € tax incl.ESD-safe PETG with ceramic particles. Does not mark and is not abrasive for the nozzle. ESD-safe PETG with ceramic particles. Does not mark and is not abrasive for the nozzle.

-

PET GF Raise3D PET GF Raise3D

65,00 € tax excl.

65,00 € tax incl.Rigid and strong industrial PET with 15 % of glass fibers, thermally and chemically resistant. Rigid and strong industrial PET with 15 % of glass fibers, thermally and chemically resistant.

-

PETG Medical - Lattice Services PETG Medical - Lattice Services

45,75 € tax excl.

45,75 € tax incl.High quality PETG for chemically resistant and skin-safe applications in medical sector. High quality PETG for chemically resistant and skin-safe applications in medical sector.

-

PolyMax PETG ESD PolyMax PETG ESD

46,95 € tax excl.

46,95 € tax incl.PETG with excellent mechanical properties and carbon nanotubes for ESD safety. PETG with excellent mechanical properties and carbon nanotubes for ESD safety.

-

Fiberlogy PCTG GF Fiberlogy PCTG GF

39,00 € tax excl.

39,00 € tax incl.PCTG with glass fiber for strong and stiff parts with weather and chemical resistance. PCTG with glass fiber for strong and stiff parts with weather and chemical resistance.

-

PETg 3NTR PETg 3NTR

A chemically resistant PETg with an excellent surface finish, suitable for food contact. A chemically resistant PETg with an excellent surface finish, suitable for food contact.

What is PET

PET (Polyethylene terephthalate) was born in the mid-twentieth century as a polymer for the manufacture of fibers, which would replace cotton fibers. Shortly after the appearance of this material, in the form of fiber, it settled in the industry, and its use in the textile sector is still pointer today. With the evolution of processing technology, PET begins to be used in the form of film for food packaging and in 1976, this polymer experienced its biggest boom with the manufacture of rigid bottles for low-oxygen-sensitive beverages, such as carbonated soft drinks, beer and mineral water.

As a PET evolution, PETG arises, a material with which more translucent objects with a lower melting point are obtained, ideal characteristics to create resistant and easy pieces of thermoforming or extrusion. Due to the ease of extrusion and thermal stability, PETG and other PET derivatives are widely used in the world of 3D FDM / FFF printing.

PETG: The ease of the PLA and the mechanical properties of ABS

The PETG as a material used in 3D printing is characterized by a functionality very similar to ABS (good temperature resistance, durable and resistant) and the ease of being printed as the PLA. It also shows good adhesion between layers, little deformation during printing, resistance to environments with low temperatures for long periods of time, chemical resistance (bases and acids) and the absence of odor during printing.

Within this category stands out the CPE HG100, a copolyester thermoplastic that presents a high resistance to impact (no breakage), great hardness, resistance to traction and thermal resistance among many other qualities. Like many other materials, PETG can also be found reinforced with fibers (carbon or aramid) to increase its mechanical strength and raise the use of these materials to industrial levels.