No products

Product successfully added to your cart

0 products in the cart 1 product in the cart

Tanks and utensils

There are 52 products.Tanks and key tools to obtain the maximum performance and effectiveness of resin 3D printers type SLA, DLP, LED-LCD and LFS.

-

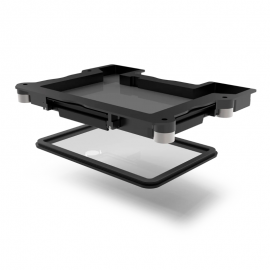

Resin vat for XiP Nexa 3D Resin vat for XiP Nexa 3D

355,00 € tax excl.

355,00 € tax incl.Official resin vat for the Nexa 3D XiP 3D printer. Official resin vat for the Nexa 3D XiP 3D printer.

-

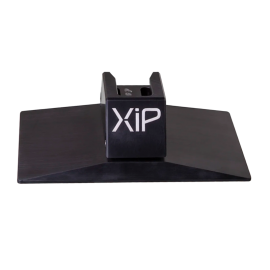

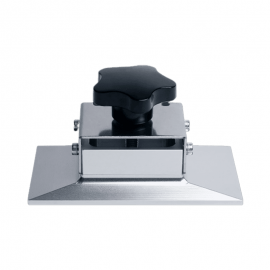

XiP build plate Nexa 3D XiP build plate Nexa 3D

239,00 € tax excl.

239,00 € tax incl.Build plate compatible with the Nexa 3D XiP printer. Build plate compatible with the Nexa 3D XiP printer.

-

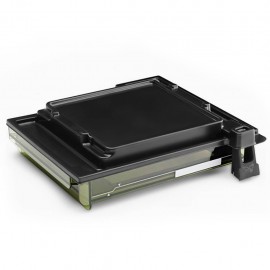

Everlast 2 Membrane for XiP Nexa 3D Everlast 2 Membrane for XiP Nexa 3D

115,00 € tax excl.

115,00 € tax incl.Replacement for the Everlast 2 Membrane for the XiP 3D printer. Replacement for the Everlast 2 Membrane for the XiP 3D printer.

-

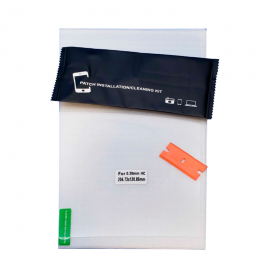

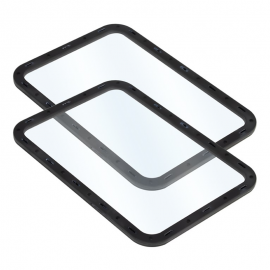

LCD screen protective kit for XiP Nexa 3D LCD screen protective kit for XiP Nexa 3D

24,00 € tax excl.

24,00 € tax incl.Official kit with everything needed for replacing the protective glass on the XiP LCD screen. Official kit with everything needed for replacing the protective glass on the XiP LCD screen.

-

Wash bucket for XiP Wash+Cure Nexa 3D Wash bucket for XiP Wash+Cure Nexa 3D

116,50 € tax excl.

116,50 € tax incl.Wash bucket for the XiP Wash+Cure post-processing station. Wash bucket for the XiP Wash+Cure post-processing station.

-

XiP Toolkit Nexa 3D XiP Toolkit Nexa 3D

115,00 € tax excl.

115,00 € tax incl.Official Nexa 3D kit with post-processing tools and accessories. Official Nexa 3D kit with post-processing tools and accessories.

-

Form 2 Resin Tank Standard (FormLabs) Form 2 Resin Tank Standard (FormLabs)

59,00 € tax excl.

59,00 € tax incl.Container where is the resin that Form 2 uses for 3D SLA impressions. Container where is the resin that Form 2 uses for 3D SLA impressions.

-

Form 2 Resin Tank LT (FormLabs) Form 2 Resin Tank LT (FormLabs)

99,00 € tax excl.

99,00 € tax incl.Most potent container of FormLabs where the resin used by Form 2 for 3D SLA impressions is. Most potent container of FormLabs where the resin used by Form 2 for 3D SLA impressions is.

-

Form 3 Resin Tank (FormLabs) Form 3 Resin Tank (FormLabs)

135,00 € tax excl.

135,00 € tax incl.Container where the resin using Form 3 and is located. Container where the resin using Form 3 and is located.

-

Form 3L / Form 3BL V3 Resin Tank (FormLabs) Form 3L / Form 3BL V3 Resin Tank (FormLabs)

275,00 € tax excl.

275,00 € tax incl.Resin tank compatible with the Form 3L and Form 3BL resin 3D printers. Resin tank compatible with the Form 3L and Form 3BL resin 3D printers.

-

Stainless Steel Build Platform (FormLabs) Stainless Steel Build Platform (FormLabs)

250,00 € tax excl.

250,00 € tax incl.Stainless steel build platform compatible with Form 2 and Form 3B. Stainless steel build platform compatible with Form 2 and Form 3B.

-

Build Platform 2 Quick release (FormLabs) Build Platform 2 Quick release (FormLabs)

229,00 € tax excl.

229,00 € tax incl.Easily removable build platform compatible with Form 2, Form 3+ and Form 3B+. Easily removable build platform compatible with Form 2, Form 3+ and Form 3B+.

-

Form 2 / Form 3 Build Platform (FormLabs) Form 2 / Form 3 Build Platform (FormLabs)

99,00 € tax excl.

99,00 € tax incl.Build Platform compatible with Form 2, Form 3 and Form 3B from Formlabs. Build Platform compatible with Form 2, Form 3 and Form 3B from Formlabs.

-

Form 3L / Form 3BL Build Platform (FormLabs) Form 3L / Form 3BL Build Platform (FormLabs)

349,00 € tax excl.

349,00 € tax incl.Build Platform compatible with Form 3L and Form 3BL from Formlabs. Build Platform compatible with Form 3L and Form 3BL from Formlabs.

-

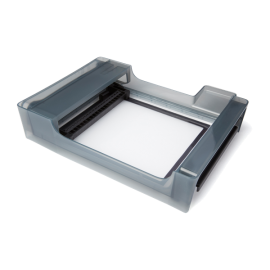

Inkspire resin tank (Zortrax) Inkspire resin tank (Zortrax)

115,89 € tax excl.

115,89 € tax incl.Resin tank compatible with the Zortrax Inkspire 3D printer. Resin tank compatible with the Zortrax Inkspire 3D printer.

-

Inkspire Manufacturing Platform (Zortrax) Inkspire Manufacturing Platform (Zortrax)

101,65 € tax excl.

101,65 € tax incl.Manufacturing platform compatible with Zortrax Inkspire. Manufacturing platform compatible with Zortrax Inkspire.

-

Zortrax Inkspire FEP Films Zortrax Inkspire FEP Films

27,45 € tax excl.

27,45 € tax incl.Jeu de 4 films FEP compatibles avec Zortrax Inkspire. Jeu de 4 films FEP compatibles avec Zortrax Inkspire.

-

SLASH Resin Tank (UniZ) SLASH Resin Tank (UniZ)

141,00 € tax excl.

141,00 € tax incl.Made with a polymeric film, specially designed to offer a low surface tension. Made with a polymeric film, specially designed to offer a low surface tension.

-

SLASH Build Platform (UniZ) SLASH Build Platform (UniZ)

119,00 € tax excl.

119,00 € tax incl.Manufacturing platform compatible with 3D SLASH printers by UniZ. Manufacturing platform compatible with 3D SLASH printers by UniZ.

-

SLASH Cover Resin Tank (UniZ) SLASH Cover Resin Tank (UniZ)

42,00 € tax excl.

42,00 € tax incl.Cover to increase the practicality of the SLASH resin 3D printers by UniZ. Cover to increase the practicality of the SLASH resin 3D printers by UniZ.

-

Resin pump tubing (UniZ) Resin pump tubing (UniZ)

39,00 € tax excl.

39,00 € tax incl.Flexible tube with high flow rate for the SLASH 3D printers by Uniz. Flexible tube with high flow rate for the SLASH 3D printers by Uniz.

-

XYZ Nobel Resin Tank XYZ Nobel Resin Tank

153,30 € tax excl.

153,30 € tax incl.The resin tank for Nobel printers is one of the key parts for its proper functioning. The resin tank for Nobel printers is one of the key parts for its proper functioning.

-

Resin tank Foto 13.3 Resin tank Foto 13.3

164,68 € tax excl.

164,68 € tax incl.Resin tank for the Flashforge Foto 13.3 printer with a volume of 1.8 L. Resin tank for the Flashforge Foto 13.3 printer with a volume of 1.8 L.

-

Manufacturing platform Foto 13.3 Manufacturing platform Foto 13.3

98,80 € tax excl.

98,80 € tax incl.Flashforge Foto 13.3 3D printer manufacturing platform. Flashforge Foto 13.3 3D printer manufacturing platform.

-

FEP Film Foto 13.3 FEP Film Foto 13.3

99,00 € tax excl.

99,00 € tax incl.FEP film for the Flashforge LCD 3D printer Photo 13.3. FEP film for the Flashforge LCD 3D printer Photo 13.3.

-

PEC*PAD wipes PEC*PAD wipes

33,50 € tax excl.

33,50 € tax incl.The perfect complement to the Novus 1 to clean the most delicate areas of the Form 2. The perfect complement to the Novus 1 to clean the most delicate areas of the Form 2.

-

Novus 1 Novus 1

22,00 € tax excl.

22,00 € tax incl.Valid acrylic cleaner to clean the most delicate areas of 3D printer. Valid acrylic cleaner to clean the most delicate areas of 3D printer.

-

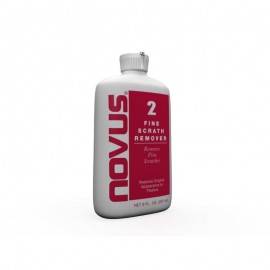

Novus 2 Novus 2

22,00 € tax excl.

22,00 € tax incl.Novus 2 removes fine scratches and discoloured areas from plastics and acrylics. Novus 2 removes fine scratches and discoloured areas from plastics and acrylics.

-

Novus 3 Novus 3

22,00 € tax excl.

22,00 € tax incl.Novus 3 removes heavy scratches and abrasions from plastic and acrylic surfaces. Novus 3 removes heavy scratches and abrasions from plastic and acrylic surfaces.

-

IPA Alcohol IPA Alcohol

16,50 € tax excl.

16,50 € tax incl.Ideal for removing resin residues from parts made with the 3D SLA printer. Ideal for removing resin residues from parts made with the 3D SLA printer.

-

xCLEAN parts washing solution Nexa 3D xCLEAN parts washing solution Nexa 3D

35,00 € tax excl.

35,00 € tax incl.Part washing solution for economical and efficient post-processing. Part washing solution for economical and efficient post-processing.

-

Liqcreate Resin Cleaner Liqcreate Resin Cleaner

74,95 € tax excl.

74,95 € tax incl.Non-toxic residue-free biodegradable resin cleaner compatible with ultrasonic cleaners. Non-toxic residue-free biodegradable resin cleaner compatible with ultrasonic cleaners.

-

TPM Wash Solvent TPM Wash Solvent

89,00 € tax excl.

89,00 € tax incl.Non-flammable solvent ideal for cleaning and dissolving uncured resin in 3D printed parts. Non-flammable solvent ideal for cleaning and dissolving uncured resin in 3D printed parts.

-

Cleaner BASF Cleaner BASF

25,00 € tax excl.

25,00 € tax incl.High quality cleaning fluid developed for BASF Ultracur3D® resins. High quality cleaning fluid developed for BASF Ultracur3D® resins.

-

Ultrasonic cleaner Ultrasonic cleaner

263,28 € tax excl.

263,28 € tax incl.Ultrasonic cleaner for cleaning 3D printed parts with resin. Ultrasonic cleaner for cleaning 3D printed parts with resin.

-

HARZ Labs Glaze HARZ Labs Glaze

33,00 € tax excl.

33,00 € tax incl.Acrylic coating for 3D printed parts that provides higher gloss and surface resistance. Acrylic coating for 3D printed parts that provides higher gloss and surface resistance.

-

Zortrax Inkspire carbon filter Zortrax Inkspire carbon filter

6,00 € tax excl.

6,00 € tax incl.Carbon odour absorbing filter compatible with Zortrax Inkspire. Carbon odour absorbing filter compatible with Zortrax Inkspire.

-

Resin filter (190 microns) Resin filter (190 microns)

0,41 € tax excl.

0,41 € tax incl.Paper filters with a mesh of 190 microns perfect for filtering the resins. Paper filters with a mesh of 190 microns perfect for filtering the resins.

-

Cutting pliers Cutting pliers

5,80 € tax excl.

5,80 € tax incl.The cutting pliers are an indispensable tool in day-to-day 3D printing. The cutting pliers are an indispensable tool in day-to-day 3D printing.

-

Resin vat Phrozen Resin vat Phrozen

75,95 € tax excl.

75,95 € tax incl.Replacement resin vats for the Phrozen 3D printers. Replacement resin vats for the Phrozen 3D printers.

-

Build plate Phrozen Build plate Phrozen

58,00 € tax excl.

58,00 € tax incl.Build plates for the Phrozen Sonic resin 3D printers. Build plates for the Phrozen Sonic resin 3D printers.

-

Light Curing Putty Phrozen Light Curing Putty Phrozen

16,52 € tax excl.

16,52 € tax incl.UV-curable putty for fixing and retouching cured parts 3D printed in resin. UV-curable putty for fixing and retouching cured parts 3D printed in resin.

-

nFEP film Phrozen nFEP film Phrozen

20,62 € tax excl.

20,62 € tax incl.Spare nFEP film for resin 3D printers, designed for long-lasting performance. Spare nFEP film for resin 3D printers, designed for long-lasting performance.

-

Silicone brush Silicone brush

7,40 € tax excl.

7,40 € tax incl.Silicone brush for easier removal of uncured resin from hard to reach places. Silicone brush for easier removal of uncured resin from hard to reach places.

-

Form 2L Build Platform Quick Release Form 2L Build Platform Quick Release

599,00 € tax excl.

599,00 € tax incl.Build platform with quick release technology. Compatible with Form 3L and Form 3BL from Formlabs. Build platform with quick release technology. Compatible with Form 3L and Form 3BL from Formlabs.

-

Ziflex Resin Starter Kit Ziflex Resin Starter Kit

71,00 € tax excl.

71,00 € tax incl.Build plates for resin 3D printers. Great adhesion and easy removal of the models. Build plates for resin 3D printers. Great adhesion and easy removal of the models.

-

FEP film for Anycubic 3D printers FEP film for Anycubic 3D printers

16,45 € tax excl.

16,45 € tax incl.FEP film in various sizes for Anycubic 3D printers. FEP film in various sizes for Anycubic 3D printers.

-

Resin tanks for Anycubic 3D printers Resin tanks for Anycubic 3D printers

24,71 € tax excl.

24,71 € tax incl.Resin tanks for the different models of Anycubic 3D printers. Resin tanks for the different models of Anycubic 3D printers.

-

Non-stick silicone mat Non-stick silicone mat

9,90 € tax excl.

9,90 € tax incl.Non-stock silicone mat for easy resin transfer. Non-stock silicone mat for easy resin transfer.

-

Silicone funnel with filter for resin Silicone funnel with filter for resin

3,95 € tax excl.

3,95 € tax incl.Flexible silicone funnel with stainless steel filter for more efficient resin filtration. Flexible silicone funnel with stainless steel filter for more efficient resin filtration.

-

Loctite 3D Cleaner Loctite 3D Cleaner

20,99 € tax excl.

20,99 € tax incl.Professional cleaners for the post-processing of parts 3D printed with the Loctite resins. Professional cleaners for the post-processing of parts 3D printed with the Loctite resins.

-

Ceramic Wash Solution Ceramic Wash Solution

189,00 € tax excl.

189,00 € tax incl.Specialized cleaning solution for ceramic 3D printed parts. Non-hazardous and non-flammable. Specialized cleaning solution for ceramic 3D printed parts. Non-hazardous and non-flammable.

Key parts of resin 3D printers: Tanks and platforms

Both the resin tank and the building platform are very important elements of 3D resin printers. The resin tank is not only responsible for containing the resin, but also must have at its base a non-stick sheet, which does not stick the piece during manufacturing, and in turn let the laser pass without causing any disturbance about him. At the moment that this sheet presents certain wear, the tank must be changed to avoid fabrication errors and solid residues of resin, which can contaminate the rest of the liquid resin. Manufacturing platforms usually have a longer life than resin tanks, as long as they are used correctly and following the manufacturer's recommendations, especially when extracting the parts.

Essential tools for 3D resin printing

To carry out all the processes involved in printing 3D resin pieces, a series of tools is needed.

The IPA alcohol is the indispensable product to work with any type of 3D resin printer. This liquid is used in the most important operations, such as cleaning the build platform, cleaning the resin tank and, above all, removing the non-solidified resin from the surface of the piece. For this process it is recommended to have two containers with IPA alcohol, the first to remove the surface resin that has not completely solidified and the second to make a rinse. Other important elements are the Novus 1 and the PEC*PAC wipes, which help keep all parts of the 3D resin printer clean, especially key areas such as the element through which the laser is projected (glass, LCD, etc.).