Note: This guide deals with the concepts in a general way and without focusing on a specific brand or model, although they may be mentioned at some point. There may be important differences in calibration or adjustment procedures between different makes and models, so it is recommended to consult the manufacturer's manual before reading this guide.

The final quality of the printed parts is strongly influenced by the quality of the raw material used in the production of the filament, as well as by the preservation of the filament.

This is because the more homogeneous and constant the filament properties are, the more uniform the extrusion will be and the better the surface quality of the final part will be.

Regarding the quality of the raw material, the use of resins from different manufacturers or the addition of recycled material can affect the thermal and rheological properties of the material. If the mixture is not completely uniform, the properties can vary throughout the filament causing small inconsistencies in the extrusion that will be reflected in the part. This is why purchasing quality filaments from reputable and reliable manufacturers is often the best option when looking for the highest print quality.

Another important factor is the preservation of the filament. The best quality filament can give poor quality or unexpected results if not stored properly. Temperature and humidity can alter and degrade the properties of the printing materials.

Effect of moisture on filaments

One of the critical factors in the preservation of printing materials and the one that often causes the most problems is the preservation of filaments in humid environments.

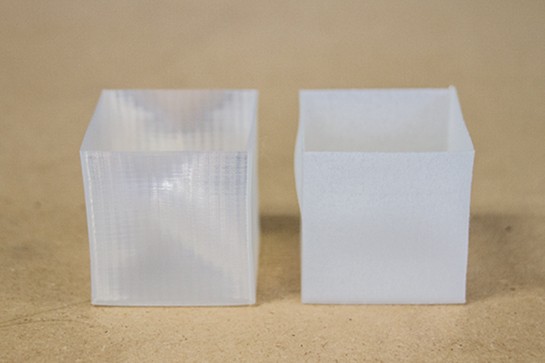

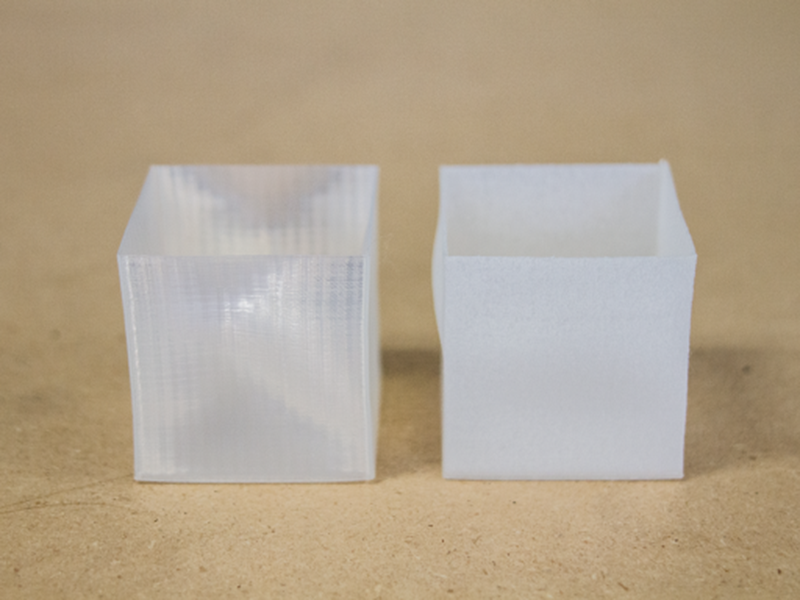

Image 1: Printed part with a filament without moisture (left) and with moisture (right). Source: all3dp.com

All plastic materials have a property known as hygroscopicity. This property defines the material's ability to absorb moisture.

To a greater or lesser extent, all filaments absorb moisture, however plastics are often classified as hygroscopic and non-hygroscopic.

Hygroscopic plastics have a high affinity for moisture uptake in large percentages. This moisture is absorbed at the molecular level throughout the material, even inside the filament. Within the filaments, the materials considered hygroscopic are:

- ABS

- ASA

- PETG

- CPE

- Nylon

- PC

- TPE

- TPU

- All derivatives of the above

To ensure maximum print quality, it is advisable to dry these materials periodically. Some, such as nylon or PC, must be dried before each use, while others, such as ABS or ASA, provide acceptable results even when saturated with moisture, due to their low degree of hygroscopicity. To reduce the drying periodicity of the filaments, it is advisable to keep them free of moisture in airtight containers with desiccant.

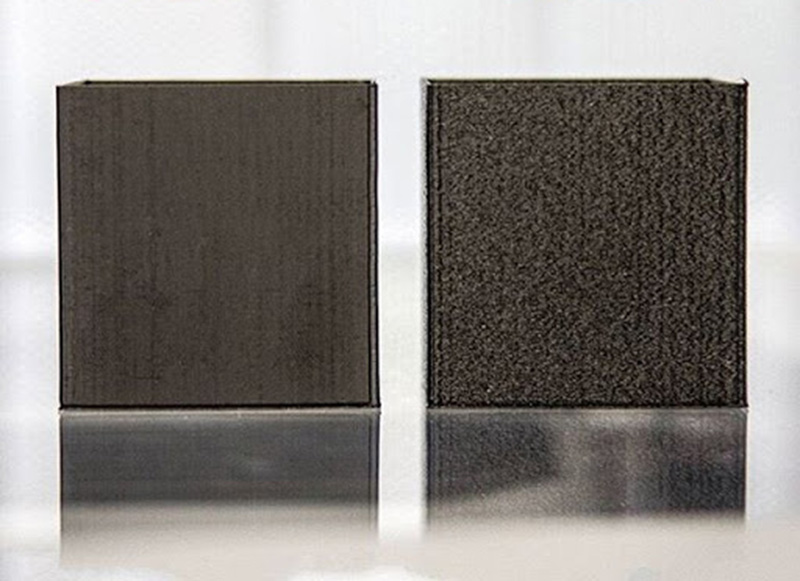

Image 2: Piece printed with wet nylon filament before drying (right) and after drying (left). Source: all3dp.com

In general, such filaments fully recover their properties after drying, however there are some specific cases of hygroscopic plastics where it is not possible to completely regenerate the material after drying. These materials are:

- PLA

- PVB

- PVA

- BVOH

- Any filament derived from the above or from water-soluble support materials.

The presence of moisture in these materials produces an effect known as hydrolysis. In this process, the water molecules break down the ester groups of the polymer, thus causing the natural degradation of the material. This is the principle by which, for example, PVA supports dissolve in water.

For these materials, storage is critical and they must be kept free of moisture in storage at all times.

Image 3: Printdry container for vacuum filament storage. Source: Printdry.com

Some filaments, such as PLA, have a very slow hydrolysis rate, so it takes weeks for the material to degrade in the presence of moisture. In these cases, the spool can be exposed to air during printing and kept dry only during storage. It is advisable to dry the material periodically to extend its life. The main indicator that a PLA filament has been degraded by hydrolysis is embrittlement of the material. A PLA degraded by moisture will be brittle and tend to break easily. In these cases, drying the filament will help to achieve an acceptable print quality, but the properties of the material will not be recovered, so the parts obtained will also be more brittle.

Image 4: Printdry pro active filament dryer. Source: Printdry.com

In the case of water-soluble support materials, such as PVA or BVOH, their hydrolysis rate is very high and the material can degrade within a few hours of exposure. It is highly recommended to store these materials in specific containers even during printing. In this case, drying the spool can be useful if the material has not been exposed to humidity for a long time, but if it has not been properly preserved it will be, in most cases, unrecoverable. A wet PVA or BVOH filament will have very poor adhesion and in many cases will cause clogging in the hotend.

Although the best way to store this type of material is to store it vacuum-packed, the most common way is to store it in airtight containers with desiccant material. However, this is usually done inadequately.

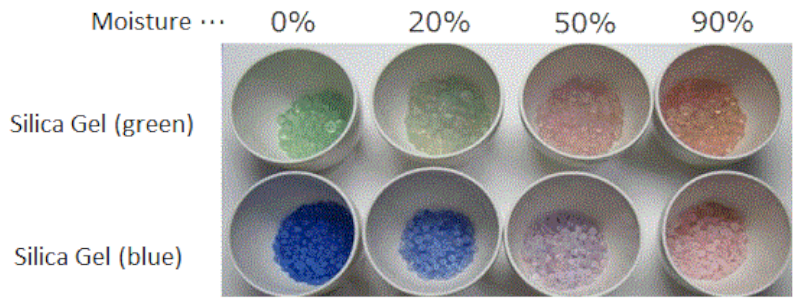

The most commonly used desiccant material is silica gel, which consists of microporous sodium silicate beads capable of capturing a large amount of moisture. This desiccant has a limited capacity to capture moisture, and once saturated, it loses its effectiveness completely.

Image 5: Silica gel bags. Source: Pixabay.com

The desiccant bags that include the filaments are usually almost saturated when we buy a material, as the manufacturers include them to remove moisture from inside the airtight bag and ensure the preservation of the material during storage prior to sale. However, when a new filament is opened for the first time, moisture is introduced back into the airtight bag, so it is advisable to replace the desiccant bags periodically..

A recommended option is to purchase reusable silica gel. This material changes colour when it becomes saturated with moisture indicating that it needs to be replaced. Saturated silica gel can be regenerated indefinitely for reuse by heating it in an oven at 180°C for a couple of hours.

Image 6: Reusable silica gel with moisture indicator. Source: labchem-wako.fujifilm.com/

A few 3D printing materials are considered non-hygroscopic and therefore do not require any special preservation measures. These are:

- PP

- HIPS

- PVC

Effect of temperature on filaments

Temperature is not usually a critical factor in the preservation of 3D printing filaments, however, there is one factor to take into account that in some specific situations can cause problems.

All thermoplastics, whether amorphous or semi-crystalline, have a property known as the glass transition temperature (Tg). When a plastic is heated above its glass transition temperature, it becomes viscoelastic, which means that any deformation of the material becomes permanent.

In general, all filaments have Tg well above the usual storage temperatures, however the problem can arise when trying to dry a filament using temperature. It is very important not to exceed the Tg for long periods of time, as this can cause variations in the filament diameter, or in extreme cases cause filament fragments to fuse together. This is why the filament should not be dried using kitchen ovens, which are unable to adequately control the temperature.

On the other hand, PLA filaments, especially the higher quality ones, have very low Tg, between 45°C and 55°C. This makes it possible to exceed this temperature in certain common situations, such as the interior of a car in summer. This makes it possible to exceed this temperature in certain common situations, such as the interior of a car in summer.

It is very important to protect 3D printing materials from humidity in order to achieve a good final quality of the parts. Some materials such as nylon or PETG can be easily dried to regenerate their properties, but others such as PLA or PVA degrade in the presence of moisture, changing their properties permanently. When drying filaments with heat, it is very important to use specialised equipment capable of precisely controlling the temperature to avoid producing deformations in the filament that could affect the print.

To ensure optimum print quality and maximum preservation of the material, it is essential to store it in suitable temperature and humidity conditions.