No products

Product successfully added to your cart

0 products in the cart 1 product in the cart

View larger

View larger

PolyMide PA612-CF is a long chain copolyimide filament from the Polymaker portfolio, reinforced with 15% chopped carbon fibers by weight. Thanks to its chemical structure, this product has lower moisture sensitivity compared to PA6/66 and PA6-based materials, and better mechanical properties than PA12-based materials. PolyMide PA612-CF's aditional advantages include high rigidity, toughness, and resistance to high temperatures. The surface finish of printed PolyMide PA612-CF objects is excellent due to better fluidity of PolyMide PA612-CF and less fiber content.

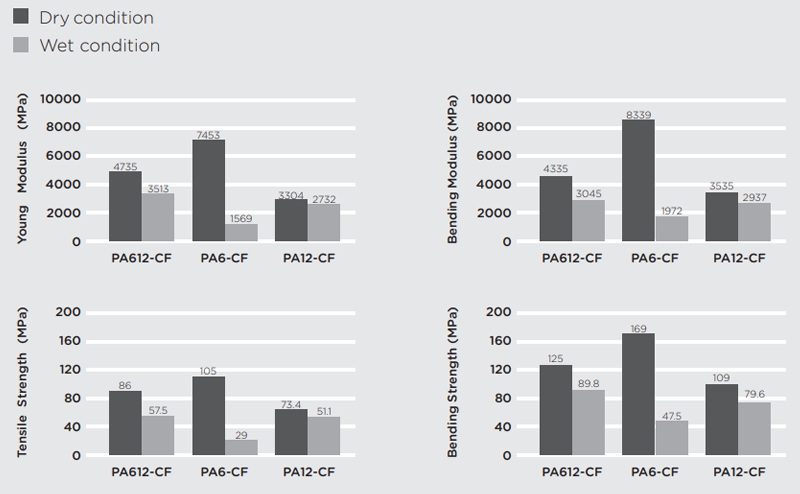

Image 1: The mechanical properties of annealed parts 3D printed with PA612-CF versus PA6-CF and PA12-CF. Source: Polymaker.

Image 1 shows a comparison of mechanical properties between the various varieties of nylon offered by Polymaker, in this case the PolyMide PA612-CF compared with the PA6-CF and PA12-CF. The dry samples were annealed at 80 ºC for 24 h and dried for 48 hours prior to testing. On the other hand, before being tested, the wet samples were immerged in ambient temperature water for 3 days.

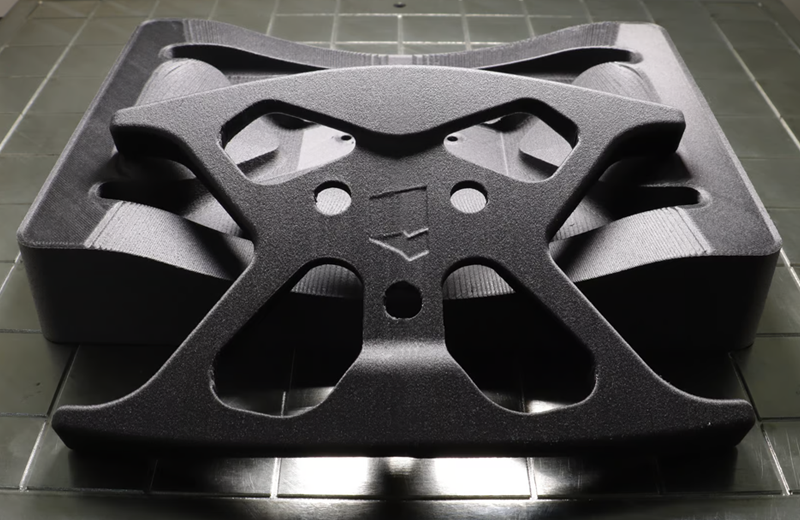

Image 2: Mounting plates for an agricultural drone 3D printed with PA612-CF filament. Source: Polymaker.

Due to is unique thermomechanical properties, the PolyMide PA612-CF filament turned out to be the perfect fit for 3D printing mounting plates for an agricultural drone. The use of PA612-CF in this application ensured the parts' vibration resistance, dimensional stability, and resistance to humidity. More about this use case can be read on the Polymaker website.

Polymaker advanced technologies

Nylon tends to warp due to its crystallization behavior, and this phenomenon can significantly influence the dimensional accuracy of printed parts. This is why, in addition to reinforcing the PA612 base with carbon fibers, Polymaker used the proprietary Warp-Free technology to enhance the size stability of the prints produced with the PolyMide PA612-CF filament. The Warp-Free technology is achieved by the fine control of micro-structure and crystallization behavior of the source nylon, which can help printed parts prevent warping and realize excellent dimensional stability.

Image 3: Part 3D printed with PA612-CF filament. Source: Polymaker.

Another cutting-edge technology applied in the PolyMide PA612-CF filament is the Fiber Adhesion technology. This solution dramatically improves the Z-axis strength, via engineering the surface chemistry of the fibers to achieve a strong fiber/matrix bonding. In contrast to conventional fiber-reinforced filaments, which exhibit considerable reduction in Z-axis strength, PolyMide PA612-CF provides higher interlayer adhesion compared to unreinforced PA612.

Printing recommendations

When using PolyMide PA612-CF as a self-support, it is important to remove the support structure right after printing. Leaving the part exposed to atmospheric moisture may result in strong bonding between the support and printed part, making support removal difficult. Alternatively, the PolySupport For PA12 can be used to 3D print the support structures for PolyMide PA612-CF. In that case, a 3D printer with a dual extruder setup is best, for example the Raise3D E2CF printer designed specially for working with fiber-reinforced filaments.

| As printed | Annealed at 80 ºC | |

|---|---|---|

| Tensile Strength (MPa) | 60.6 ± 0.27 | 86.1 ± 1.0 |

| Young’s Modulus (MPa) | 3364.6 ± 174.0 | 4735.7 ± 87.9 |

| Bending Strength (MPa) | 88.3 ± 1.8 | 125.1 ± 2.6 |

| HDT @ 1.8 MPa | 55 ºC | 115 ºC |

Table 1: The annealing process increases the parts' mechanical and thermal resistance. Source: Polymaker.

Polymaker highly recommends annealing all models printed in PolyMide PA612-CF. This allows users to take advantage of the full mechanical and thermal properties of this material. The annealing process consists of putting the model in an oven at 80˚C for 6 hours. Once annealed, the parts demonstrate significantly higher tensile strength, tensile modulus, bending strength and heat deflection temperature.

Equipment recommendations

If printing PolyMide PA612-CF at low temperature (250-260 ºC) on a general desktop 3D printer, it is highly recommended to use a hardened nickel-coated brass nozzle, for example, the Bondtech CHT BiMetal nozzle. Brass nozzle will give better thermal conductivity than a hardened nozzle such as stainless steel. Polymaker also recommends using a 3D printer equipped with a full metal hotend that can maintain a stable temperature of at least > 250 ˚C. Furthermore, PolyMide PA612-CF is a very stiff filament, so it is required to have a good setup to ensure good feeding by avoiding excessive bending in the filament guide system.

| Elongation at break (%) | 3 |

| Tensile strength (MPa) | 86 |

| Tensile modulus (MPa) | 4735 |

| Flexural strength (MPa) | 125 |

| Flexural modulus (MPa) | 4331 |

| Fiber reinforced | Fiber reinforced |

| Moisture resistance | Moisture resistance |

| Chemical resistance | Chemical resistance |

| Hide color variations | (Hide color variations) |