Product successfully added to your cart

0 products in the cart 1 product in the cart

Our webstore uses cookies to offer a better user experience and we recommend you to accept their use to fully enjoy your navigation.

More information Gestionar cookiesGestión de cookies

- Third-party cookies for analytical purposes.

- Show personalized recommendations based on your browsing on other sites.

- Show custom campaigns on other websites.

- Necessary to navigate this site and use its functions.

- Identify you as a user and store your preferences such as language and currency.

- Customize your experience based on your browsing.

Loctite 3D Cleaner

This product could be delivered in a period exceeding the standard.

New product

0 Item Items

Warning: Last items in stock!

Availability date:

Before being post-cured, parts 3D printed with resin must be cleaned in order to remove any uncured resin from the 3D printing process. While IPA alcohol is the most used substance, it does have a few disadvantages that make the Loctite Cleaner a superior cleaning solution:

- A greener, non-flammable and water rinsable alternative to IPA alcohol.

- Thoroughly cleans even complex parts such as lattice structures.

- Does not damage "green" or cured parts when used as recommended.

- Can be used for longer wash cycles when compared to IPA.

- Leaves no residue, cracks or tackiness.

The Loctite Cleaner is available in two versions: Cleaner C and Cleaner T. The main difference between the two types of the Loctite cleaner is that Cleaner C (SLA/DLP) can be used at temperatures of up to 50 ºC whereas Cleaner T (DLP) can operate safely at temperatures of up to 80 ºC.

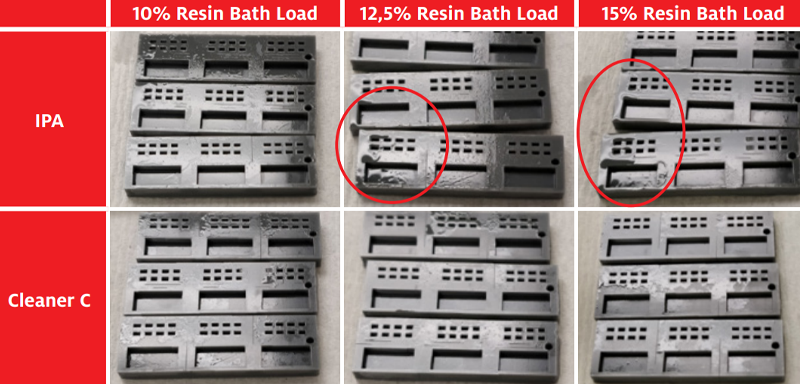

Image 1: The results of using IPA vs. the Loctite C cleaner with different levels of bath saturation. Source: Loctite.

Cleaner T is specially formulated to avoid generation of peroxides at elevated processing temperatures, which makes it perfect for the post-processing of more demanding materials such as the Loctite flame retardant 3955 HDT280 FST resin.

The post-processing instructions for both cleaners can be found in the Datasheets in the Downloads section.

| Hide color variations | (Hide color variations) |

The instructions for use of Loctite cleaners are as follows:

Loctite Cleaner C:

- Ensure you use personal safety equipment and that the workspace is properly ventilated.

- Use Cleaner C at a temperature of 20-50 °C.

- Immerse the part in Cleaner C at intervals of 2-4 minutes (typical) with a suitable mixture.

- Rinse the part with clean DI water for 1-2 minutes with agitation, optionally rinse with IPA if indicated in the material TDS.

- Dry the part properly before UV curing (typical drying settings are 60 minutes at 20-25 °C).

- Cleaning time varies depending on resin type, temperature, agitation, and part complexity.

Loctite Cleaner T:

- Ensure you use personal safety equipment and that the workspace is properly ventilated.

- Use Cleaner T at a temperature of 20-80 °C.

- Immerse the part in Cleaner T at intervals of 2-4 minutes (typical) with a suitable mixture.

- Rinse the part with clean DI water for 1-2 minutes with agitation, optionally rinse with IPA if indicated in the material TDS.

- Dry the part properly before UV curing (typical drying settings are 60 minutes at 20-25 °C).

- Cleaning time varies depending on resin type, temperature, agitation, and part complexity.

Validated printing and post-processing workflows must be followed to achieve part properties. The most up-to-date information on workflow for best results can be found here.

| Quantity | 1 kg 18 kg 195 kg |

|---|---|

| Color | - |

| Density | Cleaner C: - Cleaner T: 0.96 g/cm³ |

| Viscosity (20 ºC) | Cleaner C: 14 cP Cleaner T: 4-6 cP |

| Boiling Point | Cleaner C: 190 ºC Cleaner T: 200 ºC |

| Compatibility | Loctite Resins |

| HS Code | 2905.1 |

| Hazard and Precautionary Statements | - |

Accessories

30 other products in the same category:

-

Build Platform 2 Quick release (FormLabs)

229,00 €

-

Form 2 / Form 3 Build Platform (FormLabs)

99,00 €

-

Form 3L / Form 3BL Build Platform (FormLabs)

349,00 €

-

Inkspire resin tank (Zortrax)

115,89 €

-

Inkspire Manufacturing Platform (Zortrax)

101,65 €

-

Zortrax Inkspire FEP Films

27,45 €

-

SLASH Resin Tank (UniZ)

141,00 €

-

SLASH Build Platform (UniZ)

119,00 €

-

SLASH Cover Resin Tank (UniZ)

42,00 €

-

Resin pump tubing (UniZ)

39,00 €

-

XYZ Nobel Resin Tank

153,30 €

-

Resin tank Foto 13.3

164,68 €

-

Manufacturing platform Foto 13.3

98,80 €

-

FEP Film Foto 13.3

99,00 €

-

PEC*PAD wipes

33,50 €

-

Novus 1

22,00 €

-

Novus 2

22,00 €

-

Novus 3

22,00 €

-

IPA Alcohol

16,50 €

-

xCLEAN parts washing solution Nexa 3D

35,00 €

-

Liqcreate Resin Cleaner

74,95 €

-

TPM Wash Solvent

89,00 €

-

Cleaner BASF

25,00 €

-

Ultrasonic cleaner

263,28 €

-

HARZ Labs Glaze

33,00 €

-

Zortrax Inkspire carbon filter

6,00 €

-

Resin filter (190 microns)

0,41 €

-

Cutting pliers

5,80 €

-

Resin vat Phrozen

75,95 €

-

Build plate Phrozen

58,00 €

Categories

- Spring Sales

- 3D Printers

- 3D scanners

-

Filaments

- PLA Basic

- PLA Smartfil

- PLA Premium

- SPECIAL PLA

- Fast printing

- ABS Basic

- ABS Smartfil

- ABS Premium

- SPECIAL ABS

- ASA

- Graphene

- ADVANCED

- Metallic / Ceramic

- Flexible (TPE / TPU)

- Nylon (PA)

- Copolyesters (PET)

- HiPS

- PC (Polycarbonate)

- PP (Polypropylene)

- Support / Solubles

- Wood / Stone

- LAY / Castable

- BIO / Sustainable

- 4D filaments

- Tribo

- Cleaning

- Accessories

- Components

- Resins

- Powders

- Pellets and coloring

- STEM and education

- Handicrafts