No products

Product successfully added to your cart

0 products in the cart 1 product in the cart

The Industrial Rigid Black resin is a high-performance 3D printing resin from the portfolio of Harz Labs. Known for its exceptional chemical resistance, rigidity, and hardness, this resin was initially developed for fertilizer mixers, and has since found many applications such as lighting devices, PCB washing systems, conveyor line mounts requiring sterilization, as well as componentes of car camera washers. The resin is ideal for creating 3D-printed fittings, adapters, washing equipment components, and complex geometric models, serving both functional prototypes and finished products in demanding industrial applications.

Video 1: The Industrial Rigid Black resin. Source: Harz Labs.

Key features of this resin include low shrinkage (less than 0.5 %) and excellent dimensional accuracy, ensuring that printed models retain the exact size as designed in digital form and remain unchanged after post-curing. The resin is highly stable, with no sedimentation or gel formation occurring in the vat, eliminating the need for mixing. Additionally, it is odorless, causes no irritation, and contains no volatile monomers, making it safe for use with natural ventilation even in small workshops.

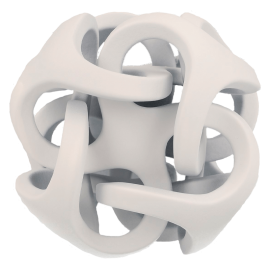

Image 1: Parts 3D printed with the Industrial Rigid Black resin. Source: Harz Labs.

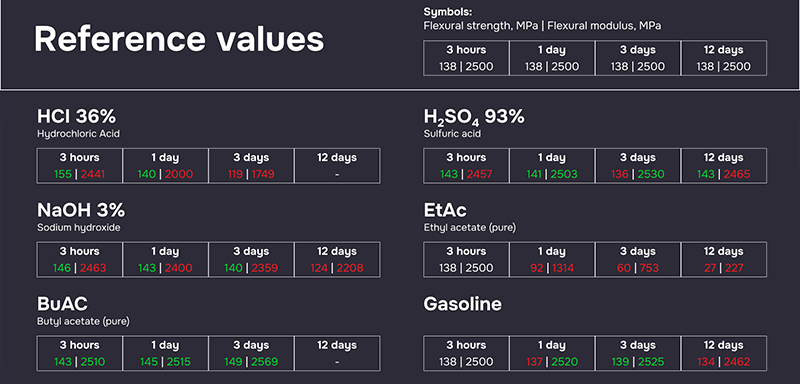

The Industrial Rigid Black resin exhibits impressive mechanical and thermal properties, including a high hardness level of Shore D 86 ± 3 and tensile strength of 75 ± 5 MPa. The material also boasts significant elongation at break of 17 ± 3% and a tensile modulus of elasticity of 970 ± 100 MPa. With a Heat Deflection Temperature (HDT) of 90 ºC at a load of 0.45 MPa, this resin is well-suited for high-temperature applications. It maintains stability when exposed to solvents and aggressive inorganic media such as acids and alkalis (see image below), making it an ideal choice for harsh industrial environments.

Image 2: The chemical resistance offered by the Industrial Rigid Black resin. Source: Harz Labs.

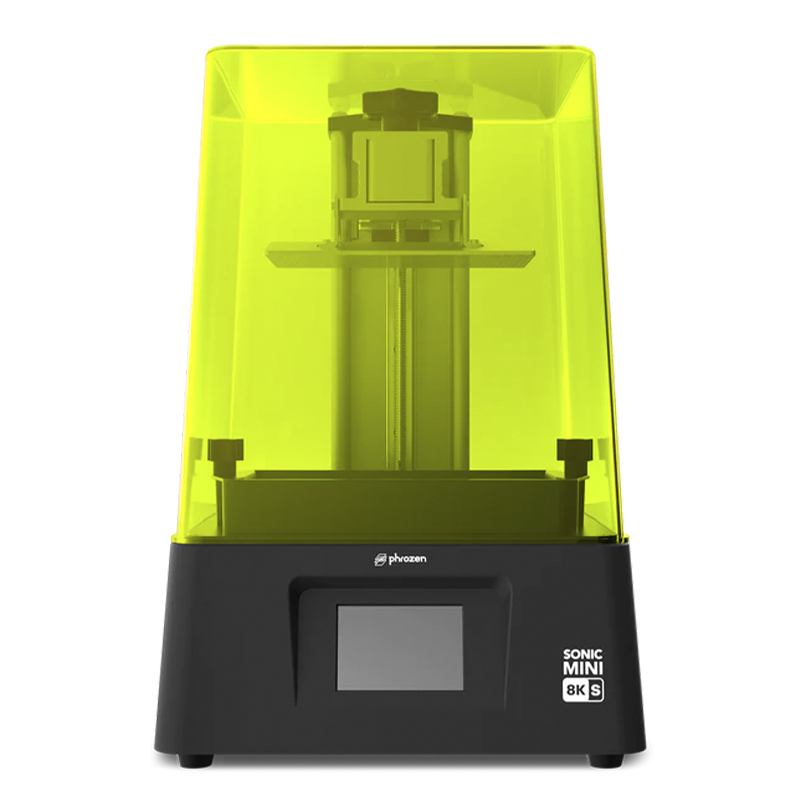

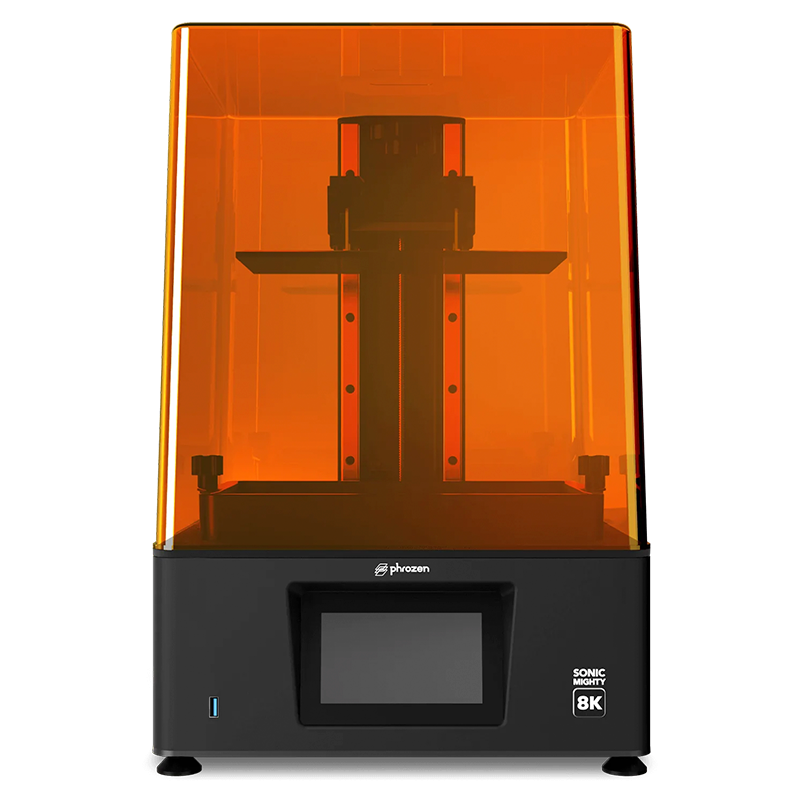

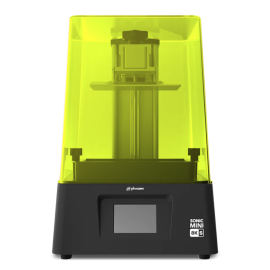

The Industrial Rigid Black resin by Harz Labs is compatible with a wide range of LCD/DLP resin 3D printers, for example the Creality Halot Mage printer, the Elegoo Mars 4 Ultra printer, the Phrozen Sonic Mini 8K S printer or the Phrozen Sonic Mighty 8K printer. The full list of compatible resin 3D printers can be consulted on the manufacturer's website.

| Elongation at break (%) | 17 |

| Tensile strength (MPa) | 75 |

| Tensile modulus (MPa) | 970 |

| Flexural strength (MPa) | 138 |

| Flexural modulus (MPa) | 2500 |

| Surface hardness | 9 |

| Chemical resistance | Chemical resistance |