No products

Product successfully added to your cart

0 products in the cart 1 product in the cart

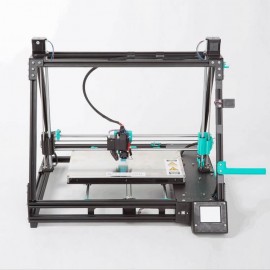

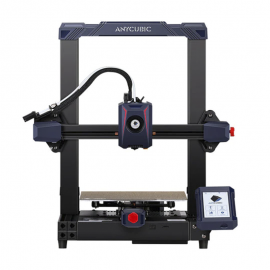

Artillery Sidewinder X3 PRO/PLUS - FDM 3D printers

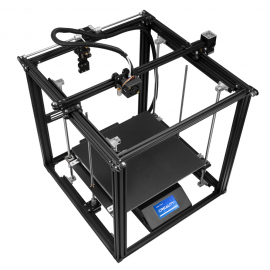

Artillery is a renowned producer recognized for the excellence of its FDM 3D printers. Artillery it offers a range of models that are highly cost-effective for casual users, granting them access to certain advanced features at a budget-friendly rate. One of the most famous printer lines by Artillery is the Sidewinder family of printers with models such as the Sidewinder X3 PRO and PLUS, high-speed 3D printers designed to print with efficiency.

Image 1: Artillery Sidewinder X3 PRO and X3 PLUS. Source: Artillery.

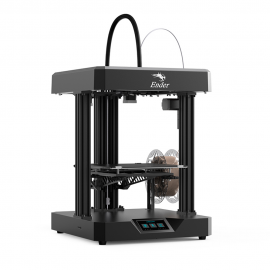

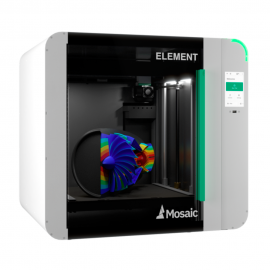

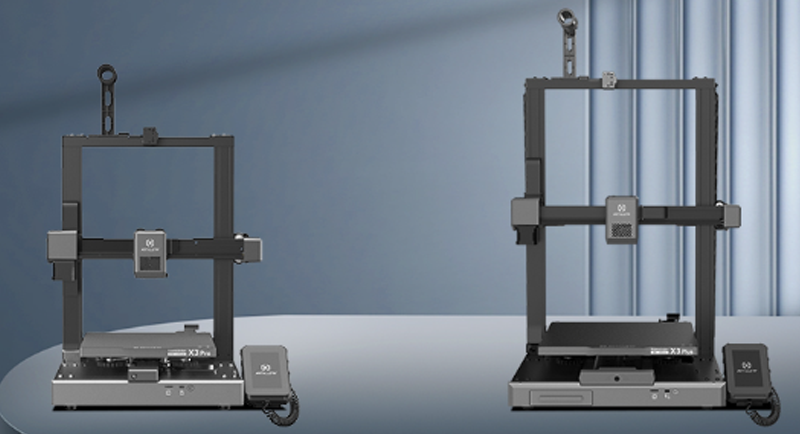

The Marlin-based X3 PRO and X3 PLUS 3D printers come 98 % assembled and are considered plug-and-play since their assembly only takes a few minutes and does not require advanced skills or tools. Detailed assembly instructions for each printer can be found in the Usage Tips section.

Image 2: The assembly only takes 5 quick steps. Source: Artillery.

Both printers' designs have received a significant upgrade with respect to their predecessor, the Sidewinder X2. The improvements include a faster printing speed, a higher extrusion and bed temperature, a wider range of compatible materials, as well as numerous hardware and usability upgrades.

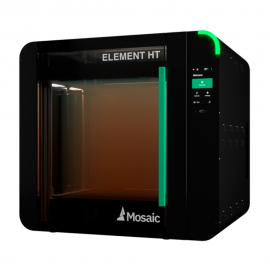

Shared features

One of the main differences between the X3 PRO and X3 PLUS 3D printers consists in their size and build volume. While the X3 PRO has the dimensions of 425 x 450 x 507 mm and a build volume of 240 x 240 x 260 mm, the X3 PLUS printer measures 492 x 507 x 610 mm and offers a build volume of 300 x 300 x 400 mm (just like Sidewinder X2).

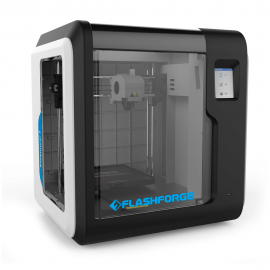

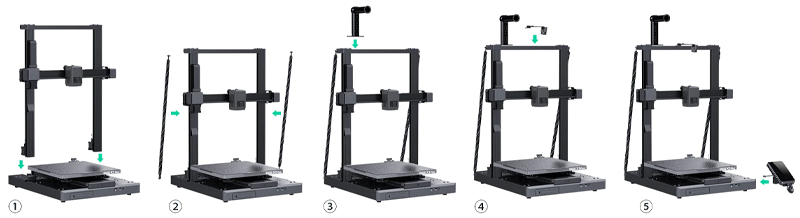

Image 3: The POM wheel and FFC cable are examples of the X3 printers' smart design. Source: Artillery.

Both 3D printers from the X3 series have a sturdy and durable chassis (in metal and ABS), all-metal guide rails and dual Z-axes with dual motors for improved coordination and stability at high printing speeds. Both printers' design has an integrated FFC (Flexible Flat Cable) cable design and a POM wheel for smooth and reliable motion with minimal friction and backlash. The FFC cable design allows for a compact and efficient layout, reducing the need for additional wiring and connectors, while also providing flexibility and reliability in data transmission or power distribution.

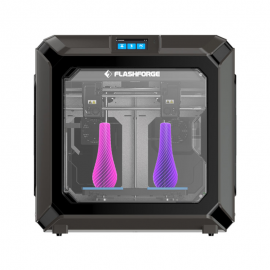

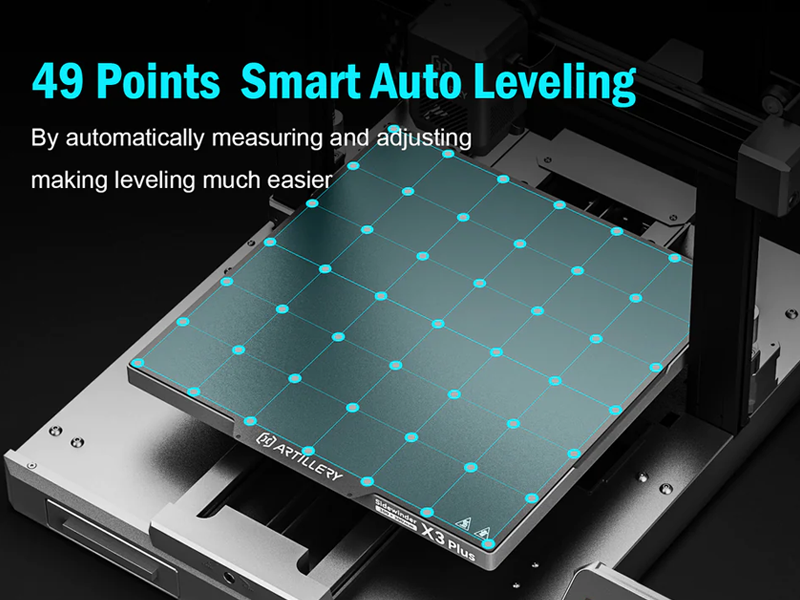

Image 4: The 49-point automatic bed leveling reduces the risk of human error. Source: Artillery.

The X3 series printers are both equipped with a PEI magnetic platform to ensure optimal first layer adhesion and successful prints. This kind of build platform has the added benefit of easy part removal by simply bending the build platform gently, reducing the risk of damaging the part of the build plate with tools. The build platform is automatically levelled via 49-point bed leveling with an inductive sensor to detect and compensate for unevenness in the heated bed.

Image 5: The 300 mm/s printing speed allows for significant productivity gains. Source: Artillery.

Both the X3 PRO and X3 PLUS 3D printer offer a maximum printing speed of 300 mm/s (acceleration speed of 3000 mm/s²). By incorporating the 5015 cooling fan, the enhanced cooling system of the Sidewinder X3 Pro ensures rapid cooling of prints at increased speeds, resulting in impeccable layering. This reduces the risk of warped prints and opens the doors to intricate designs and flawless outcomes.

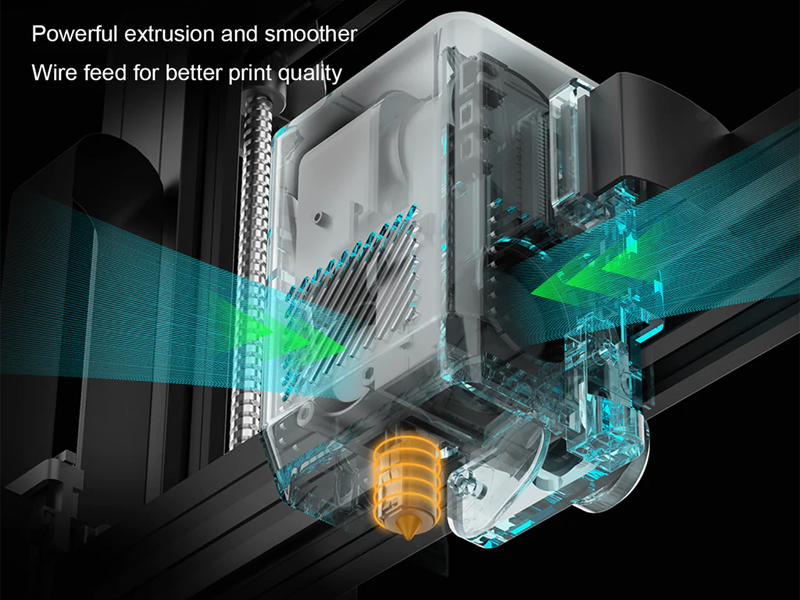

Image 6: The extruder featured in the X3 series. Source: Artillery.

The Artillery self-developed direct drive extruder, constructed entirely from metal and equipped with a dual gear set, enhances the 3D printer's drive ratio while reducing motor weight. This results in improved extrusion precision and facilitates the printing of flexible materials. Featuring an all-metal hotend with expansive melting zones and a quick-swap 0.4 mm Volcano high temperature nozzle, the Sidewinder X3 PRO and X3 PLUS offer an extrusion temperature of 300 ºC.

Image 7: The automatic cleaning nozzle featured in the X3 series. Source: Artillery.

The automatic nozzle cleaning system prevents buildup of melted polymer, thus improving the quality of the 3D printed parts and prolonging the lifespan of the nozzle and hotend by preventing clogging and deterioration. This setup guarantees efficient high-speed and high-temperature 3D printing. This capability, together with the 100 ºC bed, broadens the scope of 3D printing materials beyond PLA, PETG, TPU, fulfilling the requirements for robust filament materials such as ABS, PET and carbon-reinforced materials.

Video 1: Artillery Sidewinder X3 PRO print test. Source: Artillery.

Both printers offer an intuitive user experience featuring precise control, streamlined workflow, and real-time monitoring. The straightforward and uncluttered operational interface is available in 8 languages and has a minimalist interactive design displayed on a 4.3" color touchscreen for smoother swiping and scrolling.

Image 8: The UI of the X3 series printers is displayed on a 4.3-inch color touchscreen. Source: Artillery.

The X3 series 3D printers are both equipped with intelligent functions such as a filament runout sensor and a power loss function. The filament runout sensor prevents material waste and reduces the rate of failed prints, the power loss resume function minimizes print failures by allowing the printer to continue from where it left off after power is restored, enhancing overall print reliability and user convenience.

X3 PLUS extra features

The X3 PLUS 3D printer has two extra functions that the X3 PRO version does not include. One of them is the segmented build plate. This feature offers numerous benefits such as reduced warping and adhesion issues, simplified maintenance and cleaning, enhanced versatility in material and surface choices, as well and increased printing efficiency due to reduced cooldown time.

The last extra features incldued in the X3 PLUS printer is a top lighting. A top light in a 3D printer provides improved visibility of the print bed and surrounding area, facilitating easier monitoring of print progress and troubleshooting potential issues. Additionally, it enhances user experience by illuminating the workspace, making it more convenient to interact with the printer during operation.

| Hide color variations | (Hide color variations) |