No products

Product successfully added to your cart

0 products in the cart 1 product in the cart

View larger

View larger

Flashforge Guider 3 Ultra - FDM 3D printer

FLASHF-GUIDER-3-ULTRA

This product could be delivered in a period exceeding the standard.

New product

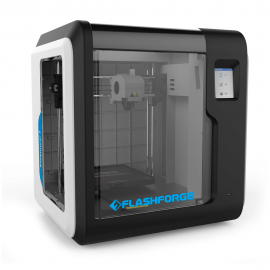

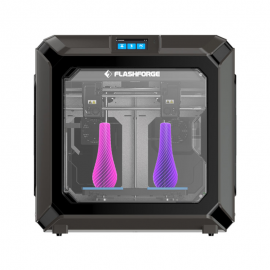

One of the FDM 3D printers offered by Flashforge in their industrial series is the fully enclosed Guider 3 Ultra printer. This 3D printer's key features include ultrahigh printing speed, lightweight and stable design, dual extrusion and a large build volume of 330 x 330 x 600 mm (single extruder) or 300 x 330 x 600 mm (dual extrusion).

Video 1: The key features of the Flashforge Guider 3 Ultra 3D printer. Source: Flashforge.

The Guider 3 Ultra printer is ideal for applications where printing speed but also part quality are both of utmost importance. Guider 3 Ultra will be a perfect addition to the additive manufacturing workflow in rapid development and validation, manufacturing assistive devices (tools, jigs, fixtures), end-use parts, architecture and art, or teaching aids.

Upgraded extrusion and leveling

The extruder of the Guider 3 Ultra printer has been redesigned with ultrahigh printing speeds in minds. By making the extruder and beam much lighter, Flashforge have managed to achieve a significant reduction in innertia at very high speeds. To make printing even faster, Flashforge has made the maintenance quicker too by including a tool-free 3-second quick-release nozzle changing system.

Image 1: The extruder structure of the Guider 3 Ultra printer. Source: Flashforge.

The Guider 3 Ultra extrusion system is capable of working at temperatures of up to 350 ºC. This and the printers well-insulated fulle enclosed chamber allow for the use of a very wide range of standard as well as engineering filaments requiring very demanding and controlled printing environments. Furthermore, the powerful dual-fan part cooling system of the Guider 3 Ultra printer also contributes to excellent printing results by ensuring that the extruded filament as well as each layer are cooled fast enough at such high printing speeds.

Video 2: Dual extrusion with Guider 3 Ultra. Source: Flashforge.

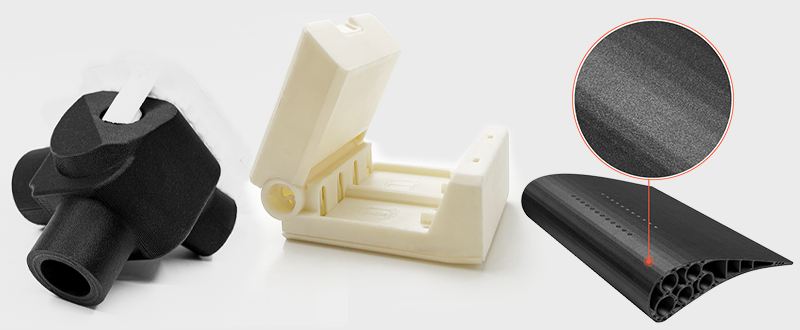

Thanks to this efficient extrusion system, Guider 3 Ultra can work with a wide variety of filaments, such as ABS, PLA, PC, PA, PP, ASA, HIPS, TPE and PETG, and even fiber reinforced filaments such as PA CF, PLA CF, PETG CF, PETG GF or PA GF (this will require an abrasion resistant nozzle with a >0.4 mm diameter). What's more, Guider 3 Ultra is an open material printer, which means that third party materials can be used, for example by BASF or Polymaker. This makes the printer even more versatile, allowing the user to choose from the rich offer of 3D printing filaments available on the market.

Image 2: One-click automatic bed levleing ensures ultimate accuracy. Source: Flashforge.

As far as bed leveling, this feature has been upgraded too in order to give the Guider 3 Ultra printer even more reliable. With just one click on the printer's highly responsive 7" LCD touchscreen the user can begin a fully automatic bed leveling and enjoy precision with no room for human error and no user intervention.

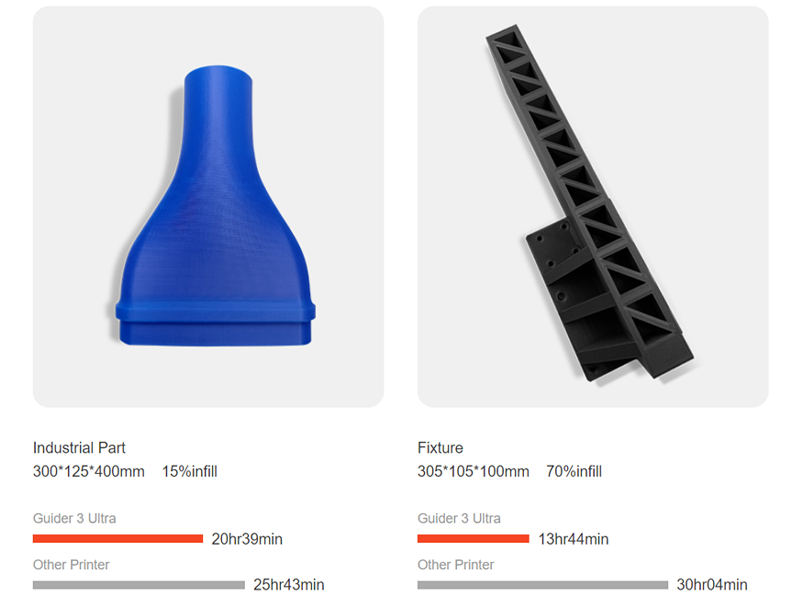

Speed and stability

Guider 3 Ultra was built to deliver superb performance in high-speed environments. With a printing speed of up to 500 mm/s, acceleration of up to 20000 mm/s² and a flow rate of up to 32 mm³/s, Guider 3 Ultra delivers large parts or batches of parts up to 3-5 times faster than most similar printers on the market, allowing for agile production of regular-size models within 24 hours and a productivity increase of up to 400 %.

Image 3: Guider 3 Ultra facilitates same-day additive manufacturing. Source: Flashforge.

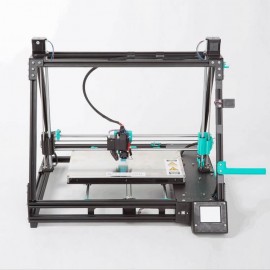

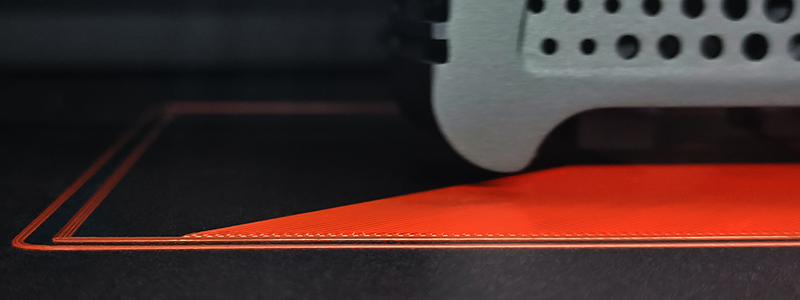

High printing speeds carry the risk of reduced stability and thus lower performance of a 3D printer. Nevertheless, Guider 3 Ultra has been carefully designed and built with high quality materials and components to ensure ultimate stability even at printing speeds of 500 mm/s. Guider 3 Ultra is equipped with high-strength dual Z-axis TBI ball screws and a stable load-bearing platform, which guarantees precise positioning of each layer.

Image 4: The stability of the printer's structure ensures perfect layers. Source: Flashforge.

Guider 3 Ultra offers the same level of stability even after 10000 hours of continuous use. Furthermore, extruder switching in the dual extrusion printing mode does not influence the printer's stability, as demonstrated in 100000 trials performed at the Flashforge laboratory.

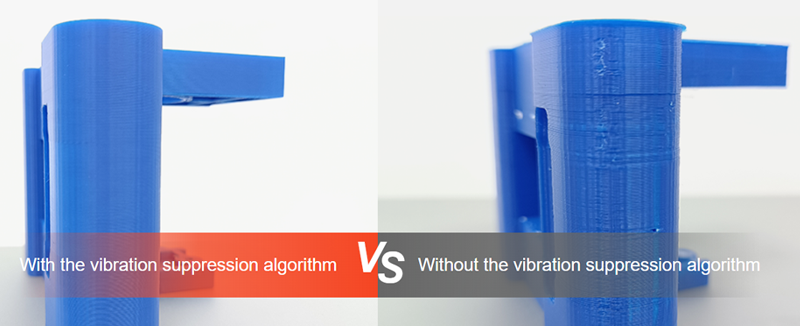

Image 5: The results of printing with and without the vibration suppression algorithm. Source: Flashforge.

Another way in which Flashforge ensures the stability of Guider 3 Ultra and perfect prints each time is by employing the vibration suppression algorithm in the FlashPrint laminating software. With the help of this technology, each layer is deposited perfectly, with a smooth finish and no ghosting/ringing. This happens with the help of a precise management of the quantity of the extruded filament in advance.

Image 6: Curves and complex geometries printed with the Guider 3 Ultra printer. Source: Flashforge.

Guider 3 Ultra also perfectly executes challenging prints such as curvatures or complex geometries and structures (overhangs, bridges and hollow structures) with stunning surface finish and great dimensional accuracy (±0.15 mm tolerance). This is also facilitated by the dual extrusion system of the printer which allows for the use of support filaments.

Smart and safe printing

Guider 3 Ultra has been given many features that make it an intelligent 3D printer that is easy to use, sustainable, and allows for a high level of control over the production process:

- Power loss recovery: in case of an unexpected power failure, Guider 3 Ultra will automatically save the printing progress, making it possible to continue printing once the printer has been restarted.

- The printer turns off automatically once the model is ready. This saves power consumption and guarantees safe operation.

- The printer detects any abnormal filament behavior such as filament run-out or clogging, stops automatically and notifies the user. This prevents the part and nozzle from being damaged, and helps save material and energy.

- The dust, odor and particles generated during the printing process are effetively removed by the inbuilt HEPA 13 air filtration system. Any harmful gases are discharged through pipes connected outside, thus ensuring an environment-friendly and safe working environment.

Video 3: The inbuilt filament drying chamber. Source: Flashforge.

Guider 3 Ultra also has an inbuilt sealed filament drying chamber in the back of the printer to ensure optimal filament condition for every print even with the most hygroscopic materials.

Remote control

The Guider 3 Ultra user interface is simple and intuitive but very powerful and highly sensitive. The 7-inch LCD touch screen and the integrated HD camera function allow the user to fully control, coordinate and monitor (time-lapse videos) the 3D printing process at all times.

This is also possible through remote multi-platform management of 3D printers via the FlashPrint laminating software. The intelligent maintenance assistant provides solutions to common printing problems, saves communication time and realizes efficient maintenance. This feature, in combination with the Guider 3 Ultra intelligent functions described above, is especially convenient on 3D printing farms as it allows for a stable and continuous 24/7 operation, with minimium user intervention.

Video 4: The FlashPrint 5 laminating software. Source: Flashforge.

The FlashPrint laminating software ensures highly successful slicing even for beginners, making available to the user default parameters for most common filaments. The accepted input formats are 3MF, STL, OBJ, FPP, BMP, PNG, JPG and JPEG, and the output formats are GX, G file and Gcode.

The Guider 3 Ultra offers many connectivity options through a USB drive, Ethernet or WiFi, and it is compatible with Windows XP, Vista 7/8/10, and Mac OS. Users who are used to working with the Slic3r or Cura laminating software can continue doing so as Guider 3 Ultra is also compatible with them (set up required).

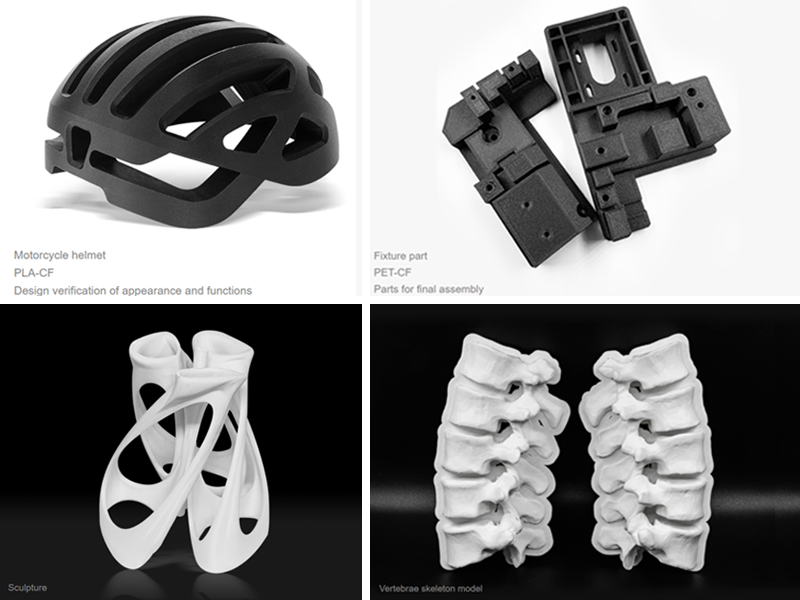

Multiple applications

By designing the Gudier 3 3D printer, Flashforge has created a powerful industrial-grade tool for tasks as varied as rapid prototyping, the manufacture of jigs and fixtures, end-use-part manufacturing, or uses in the world of teaching or architecture, design and art.

Image 7: The potential uses of the Guider 3 Ultra printer. Source: Flashforge.

The ultrafast printing speed, high stability, excellent surface finish, dual extrusion, high material compatibility and multiple safety features of the Guider 3 Ultra printer make it an incredibly rentable, versatile and reliable investment that is going to increase productivity, agilize the 3D printing workflow and allow for coordinated additive manufacturing with multiple printers for even better results.