No products

Product successfully added to your cart

0 products in the cart 1 product in the cart

View larger

View larger

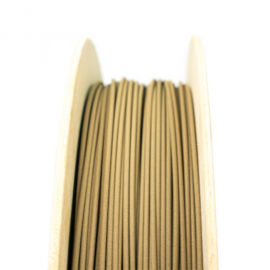

The FTile Silica filament by Colfeed4Print is a composite material made up of inorganic silica frit and a PLA matrix. This filament was designed for the additive manufacturing of complex designs that will turn into colored glass glazes after a thermal treatment at 800-900 ºC.

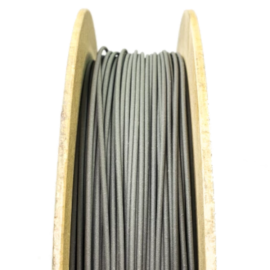

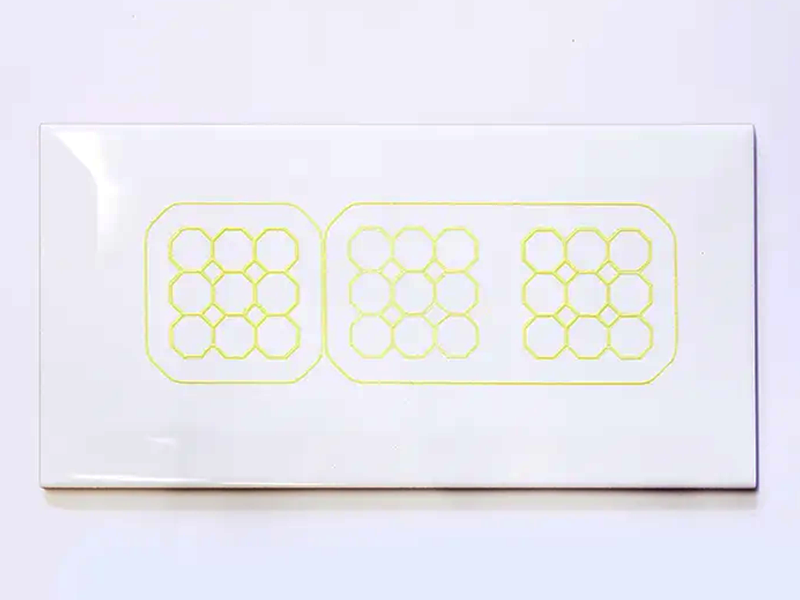

Image 1: Pattern 3D printed with the FTile Silica filament before firing. Source: Colfeed4Print.

Frit is a powdered glass material that is used in the creation of ceramic objects via ceramic 3D printing. In the case of the FTile Silica filament by Colfeed4print, the silica frit (silicon dioxide, 40 vol. %) is mixed with high quality biodegradable PLA as the binder to create the FTile Silica filament. During the firing process of the part 3D printed with the FTile Silcia filament, the PLA binder burns away, leaving behind the solidified frit particles fused together to form the final glass object.

Image 2: Pattern 3D printed with the FTile Silica filament after firing. Source: Colfeed4Print.

The FTile Silica filament is a great solution for artists and designers who want to create highly customized and complex sculptures, art installations, and decorative objects with glazed ceramic reliefs with a glassy look with the help of additive manufacturing.