For some time now, it has been possible to find metal filaments for FDM 3D printing on the market, but they are not all the same. What are the differences between them?

To answer this question, the difference between metallic coloured filaments and metallic filled filaments must be taken into account. The former contain a small amount of metallic particles (5 % - 40 %) to give a metallic appearance, used solely for their aesthetic properties. The higher the percentage of particles, the better the simulation of the metallic material in question.

In the case of metal-filled filaments, the metal particle loading is usually very high (over 80 %) and it is possible to subject 3D printed parts to a sintering process whereby the binding polymer is removed, resulting in 100% metal parts.

Currently, BASF and The Virtual Foundry are two of the best known manufacturers offering such materials with which to manufacture all-metal parts using FDM 3D printing and a sintering process.

BASF offers Ultrafuse filaments, including Ultrafuse 316 L and Ultrafuse 17-4 PH.

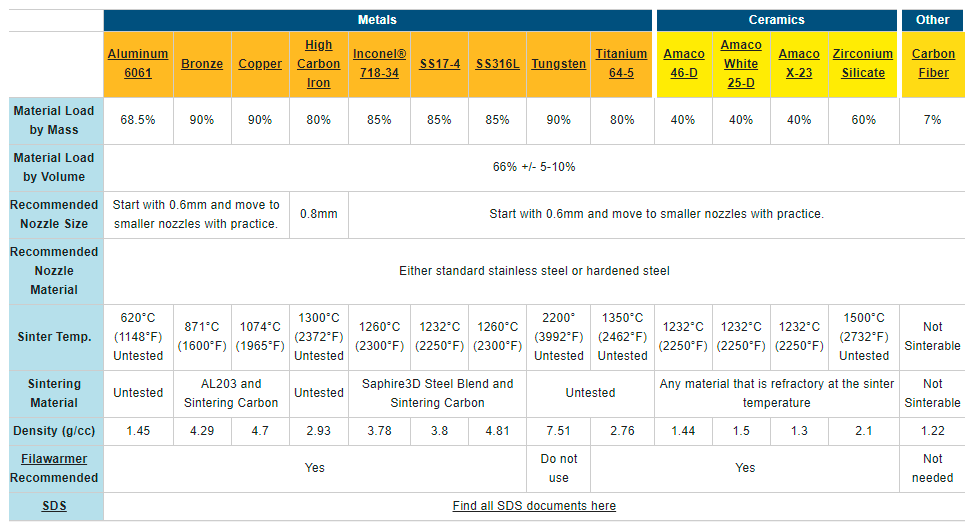

The Virtual Foundry, on the other hand, has developed a large number of metal filaments under the Filamet name, such as: Filamet Stainless Steel 316L, Filamet Bronze, Filamet Copper, Filamet Aluminium 6061, Filamet High Carbon Steel, Filamet Tungsten, Filamet Inconel 718-34 or Filamet Titanium 64-5.

Compatibility with FDM 3D printers

One of the key features of metal filament is that you don't need to have industrial FDM 3D printing equipment, or even a professional one. Metal filaments such as Ultrafuse or Filamet are characterised by the fact that they can be 3D printed on almost any FDM 3D printer on the market.

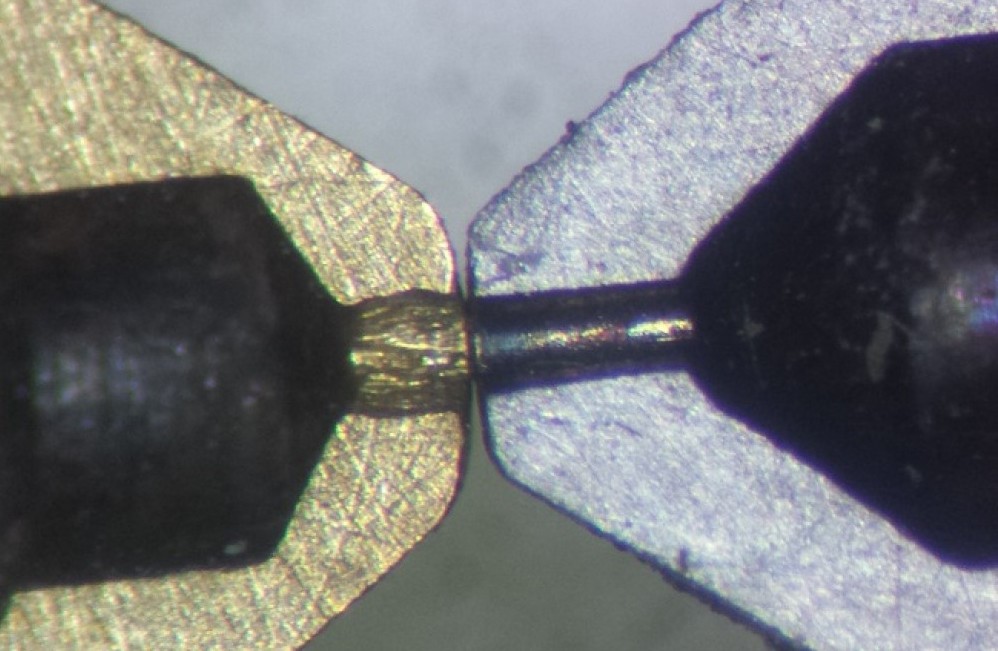

Due to the high metal loading of these filaments, a hardened steel nozzle must be used to reduce the abrasion of the filament. Print and hot bed temperatures vary by manufacturer and material, but do not exceed 245°C print temperature and 120°C for the hot bed.

Image 1: Wear of brass nozzle vs. hardened steel. Source: E3D.

In the case of Basf's Ultrafuse filaments, the nature of the filament offers a certain flexibility and is not very brittle, making it very easy to print.

The Virtual Foundry's Filamet filaments are composed of a high percentage of metal filler and PLA as the binding polymer. Depending on the metal and filler percentage of the material, Filamet filaments can be somewhat brittle, and can be difficult to print on some 3D printers because of the path the filament must take from where the spool is placed to the extruder. However, this is not a problem, as The Virtual Foundry has developed Filawarmer, a device that ensures that the filament is completely straight before printing, eliminating the curvature of the winding and achieving optimal 3D printing of the material.

Video 1: Filawarmer installation. Source: The Virtual Foundry.

Dimensional shrinkage

Metal filaments require sintering post-processing to remove the bonding polymer from the filament, resulting in all-metal parts.

As it is a process in which material is removed, it must be taken into account that the dimensions of the resulting parts will have certain variations with respect to the original measurements. That is to say, the parts will undergo greater or lesser shrinkage during the sintering process depending on the material and the brand of filament.

This is undoubtedly a difficulty when manufacturing functional parts where dimensional accuracy is a priority. However, it is possible to find the shrinkage factor and scale the CAD models to obtain the desired dimensional results.

Here, Ultrafuse and Filamet materials have some differences. Ultrafuse filaments have a shrinkage range of 16-17% in the XY axis and 19-20% in the Z axis, compared to a shrinkage of 7-10% for Filamet filaments.

In the case of Filamet, the final parts have a density of 80-85 %, although the parts can be sintered for a longer time, which would imply a higher density and a higher shrinkage compared to the original parts.

For Ultrafuse, BASF offers a comprehensive user guide including information on tolerances, shrinkage and scaling, recommended wall thickness, etc. which can be very useful.

Video 2: Ultrafuse Design Guide. Source: BASF.

Sintering process

The sintering processes developed for Ultrafuse and Filamet filaments have certain differences between them.

BASF uses a specific binder polymer in Ultrafuse filaments that requires catalytic debinding prior to the sintering process, so the post-processing can be considered somewhat more complex than for Filamet filaments. However, within the Filamet filaments, there are some that still have an experimental sintering process, which does not offer any kind of guarantee in terms of results.

Also, most of the Filamet filaments have fewer requirements in terms of sintering facilities, as most of them can be sintered in an open environment furnace.

Image 2: Filamet information table. Source: The Virtual Foundry.

A priori, the use of these filametes may raise certain doubts and difficulties, especially if the user does not have the means to carry out the sintering of the materials. However, both manufacturers offer solutions in this respect. BASF has its own sintering service, while users who wish to work with Filamet filaments can contact us to assess the feasibility of their projects and carry out the necessary post-processing to obtain the desired result.

Image 3: BASF's sintering service.

Conclusions

Filamet's range of metal filaments is undoubtedly the widest on the market. The Virtual Foundry was the first manufacturer to launch sinterable metal filaments on the market and has developed a wide range of materials suitable for a multitude of applications.

The Ultrafuse filament range currently specialises in the development of stainless steel filaments, although they can be used for a wide range of applications such as tooling, jigs and fixtures, small series production, functional parts and prototypes.

When it comes to 3D printing, Filamet filaments require a lower printing and bed temperature than Ultrafuse filaments, although some Filamet materials require the use of external devices such as Filawarmer to ensure an optimal result.

Ultrafuse filaments allow the use of smaller exit diameter nozzles, while Filamet filaments require the use of a 0.6 mm nozzle, with the exception of Filamet Tungsten.

As for the sintering process, the post-processing to which Filamet metal filaments must be subjected is simpler and, in many cases, does not require the use of an inhert atmosphere furnace, so it can be relatively easy to have the necessary facilities and machinery to sinter 3D printed parts with Filamet. Furthermore, if the user does not have the necessary facilities or knowledge to carry out the sintering, he can contact us. On the other hand, some of the Filamet filaments are in the experimental phase, so there are no guarantees regarding the sintering of these materials.

In the case of Ultrafuse, parts 3D printed with these filaments must undergo somewhat more complex post-processing, although BASF offers a comprehensive guide with relevant information on how to achieve optimal results with Ultrafuse filaments. In addition, BASF has a debinding and sintering service provided by ELNIK, based on the purchase of vouchers that cover the debinding and sintering process, as well as the shipping and return of the parts.

Undoubtedly, metal filaments are innovative materials that enable FDM 3D printer users to manufacture all-metal parts for a variety of applications. With Ultrafuse and Filamet, users can find the material that best suits their needs.