Sintering can refer to a manufacturing process that involves the compacting and heating of powdered materials to form a solid mass. In 3D printing, however (especially with metal or ceramic filaments), the word sintering also refers to post-sintering - an additional step required to give the 3D printed part its final mechanical properties. In this context, sintering usually follows debinding (removing the bonding polymer) and involves heating the 3D printed part to a temperature below the material's melting point in order to get rid of any voids or porosities. The metal or ceramic particles are fused together, reducing the porosity and increasing the part's density and strength. The sintering process is typically carried out in a controlled environment, such as a furnace or specialized sintering equipment.

Image 1: A part placed in a sintering furnace. Source: Zetamix.

There are a number of sintering methods, such as conventional sintering (solid-state sintering), pressureless sintering, hot isostatic pressing (HIP), spark plasma sintering (SPS), electric field-assisted sintering, and microwave sintering. The latter utilizes microwave radiation to heat the material rapidly and uniformly. The electromagnetic waves directly interact with the material, generating heat through molecular excitation. Microwave sintering can reduce processing time, enable energy-efficient sintering, and is often employed for ceramics and some metal powders.

Microwave sintering vs. conventional sintering

There are a number of differences that distinguish conventional sintering from microwave sintering:

- Heating methods: in conventional sintering, heat is primarily generated by external heating elements and then transferred to the material through conduction. In contrast, microwave sintering uses electromagnetic waves to directly excite the material's molecules using its dielectric properties. The electromagnetic waves penetrate the material, causing rapid and volumetric heating from within.

- Heating rate and time: unlike conventional radiative heating, which can take hours or even days, microwave sintering achieves the desired results in just a few minutes via volumetric heating.

- Temperature uniformity: microwave sintering can provide more uniform temperature distribution, as the microwave energy is more evenly absorbed by the material, leading to reduced thermal gradients and improved temperature uniformity.

- Energy Efficiency: microwave sintering is generally more energy-efficient than conventional sintering. Since microwaves directly heat the material, there is less energy loss through conduction and radiation. This efficiency can contribute to reduced energy consumption and costs of sintering.

- Porosity and microstructure: the rapid heating and shorter processing times in microwave sintering can affect the size, distribution, and morphology of pores within the material.

- Applicability: microwave sintering, while also applicable to metals, ceramics, and composites, is particularly advantageous for materials that have high dielectric losses and respond well to microwave heating.

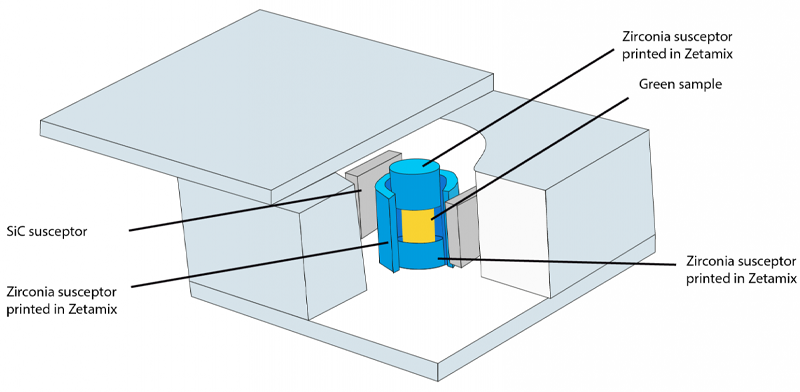

Image 2: Design of the sintering cell. Source: Zetamix.

A feature unique to microwave sintering is the use of susceptors, especially when the sintered material has low dielectric losses or needs enhanced heating efficiency and temperature uniformity. Susceptors are materials specifically chosen for their ability to absorb microwave energy and convert it into heat. They are strategically placed within the sintering system to enhance the heating process. Susceptors are typically materials with high dielectric losses, meaning they have a high capacity to absorb and dissipate microwave radiation. Common materials used as susceptors include graphite, silicon carbide, boron nitride, and certain metal oxides.

The experiment

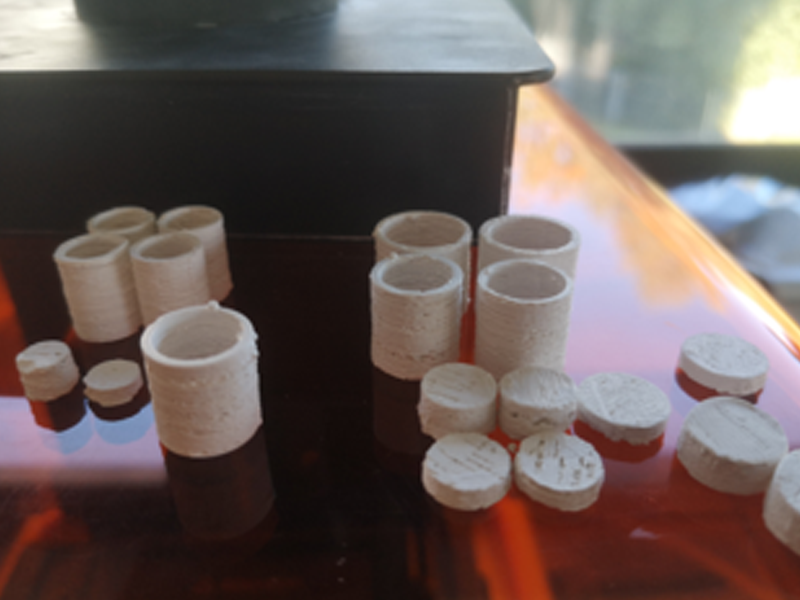

Zirconia, also known as zirconium dioxide or zirconium oxide (ZrO2), is not commonly used as a susceptor due to its relatively low dielectric losses and low microwave energy absorption. Nevertheless, the French CRISMAT laboratory specialized in crystallography and materials sciences decided to use the Zetamix White Zirconia filament to 3D print and test zirconia susceptors for microwave sintering.

The project, developed under the triple supervision of CNRS, ENSICAEN and the University of Caen Normandy, investigates the synthesis and the optimization of the functional and structural properties of ceramics materials, but also the improvement of sintering and development of innovative shaping processes.

The specific technology used is flash microwave sintering, also known as spark plasma sintering (SPS). This advanced sintering technique combines the benefits of microwave heating and electric field-assisted sintering. It is a fast and efficient method used to densify powders into solid materials, typically ceramics, metals, or composites, with enhanced properties.

Additive manufacturing and Zetamix to the rescue

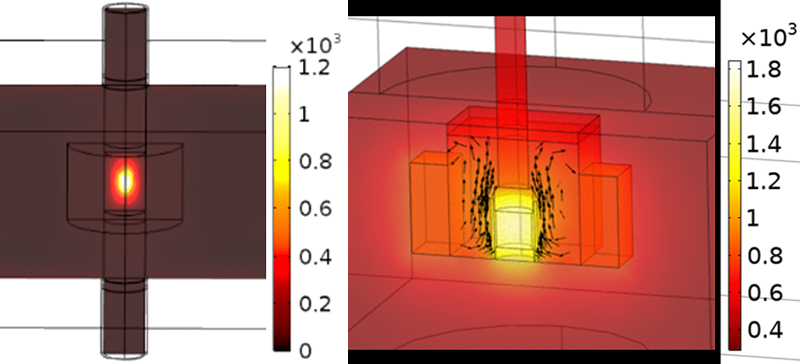

In order for flash microwave sintering to be carried out, the material needs to undergo complete densification within less than 60 seconds. Achieving the required temperature and heating rates requires precise control over thermal gradients. To address this, the laboratory has devised a cascade strategy involving two different susceptor materials: silicon carbide (SiC) and zirconia (ZrO2).

Image 3: Hot spot without susceptor vs homogeneous heating with printed susceptors. Source: Zetamix.

The process is the following: it begins with microwave heating of SiC plates, which subsequently transfer heat to zirconia blocks and cylinders. This sequential heat transfer enables rapid sintering of any material within a few seconds. However, this process can be highly demanding, potentially resulting in sample damage due to thermal gradients. To mitigate this issue and minimize thermal cooling effects, it is crucial for the zirconia susceptor to be an exact fit for the sample. Ordering a customized cylinder from external sources is extremely costly, leaving the laboratory forced to explore alternative solutions, such as additive manufacturing.

Image 4: Zirconia susceptors 3D printed using Zetamix filament. Source: Zetamix.

Through the integration of the flexibility and shape versatility provided by Fused Filament Fabrication (FFF) and the unique characteristics of Zetamix filaments, the CRISMAT laboratory successfully achieved their objectives and produced susceptors that were precisely tailored to suit the specific sample for sintering. In this way, additive manufacturing has once again overcome the cost barrier commonly associated with traditional manufacturing, and contributed to the furthering of science.