In the use of 3D printers (FFF/FDM), problems and unforeseen events (especially in non-professional 3D printers) can appear when printing the models that the user needs. This causes inconvenience, delays and other inconveniences that the user of the 3D printer never wants to happen to him. This article then provides a series of advice on how to solve these typical problems.

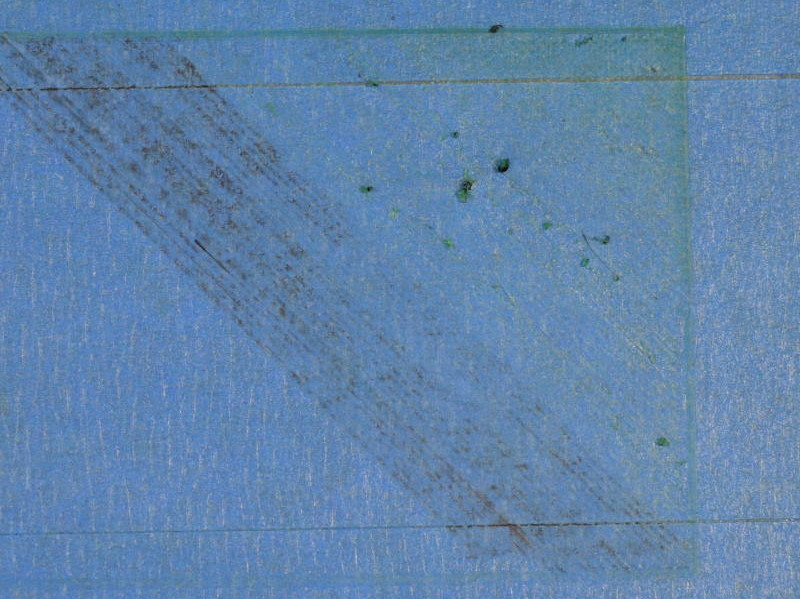

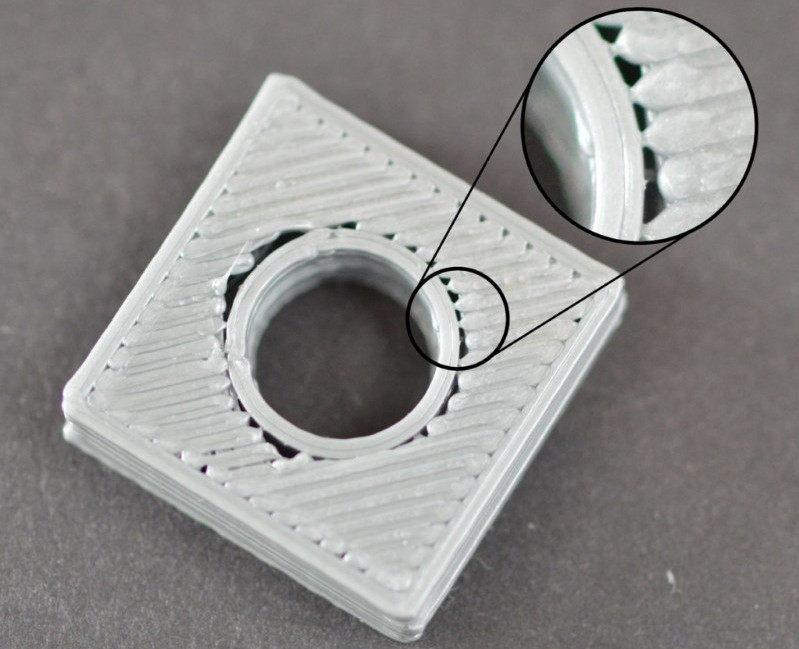

Absence of filament at the beginning of printing

When printing begins, it may be the case that no amount of filament is released. This may be due to:

Base height very close to the nozzle

This is solved by making a leveling of the base.

Extruder excessive temperature

Due to waiting at the beginning of printing, it may be the case that the material that is at the end of HotEnd is deposited in the base due to the effect of gravity itself, causing an absence of material at the time of printing.

Bad regulation of extruder tension

If the tensioner is very loose, it can happen that the filament does not move through the extruder, however, if it is very tight, it will mark the filament causing poor surface quality of poor quality.

Clogged extruder

This problem is one of the worst that can happen to a 3D printer. When this happens, the first step is to overheat the temperature in about 10 - 20 °C in reference to the last material used and introduce a cleaning filament (Smart Clean cleaning filament) until it comes out clean and continuous.

A good trick is to activate the option of the contour line around the piece (skirt) and thus ensure the output of material from the extruder before starting the printing of the piece itself.

Image 1: Absence of filament at the beginning of printing. Source: Simplify3D.

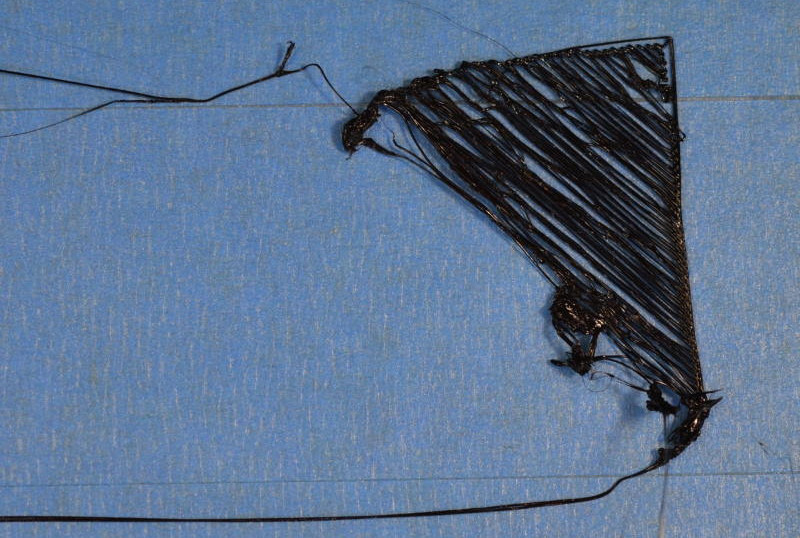

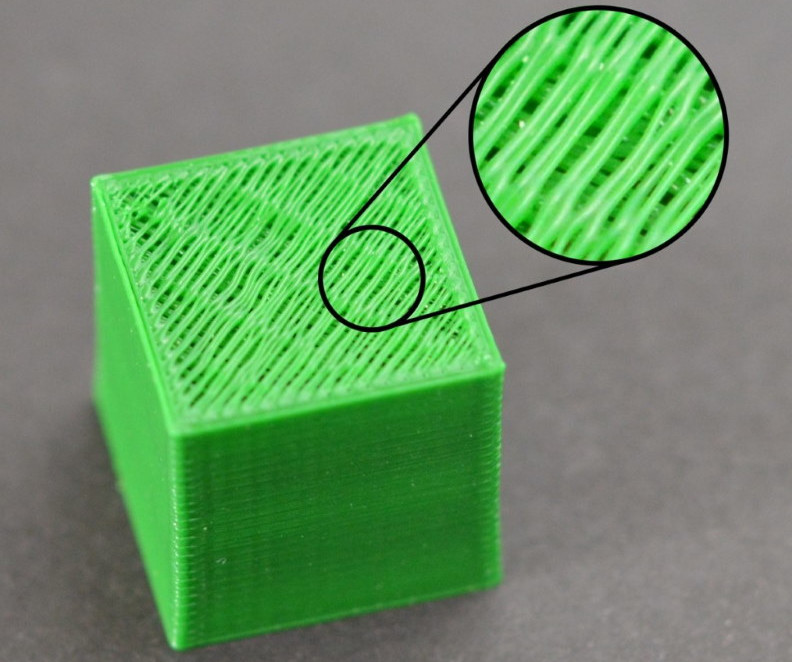

Problems with the first layer

Having solved the problem of the lack of filament at the beginning of printing, it may happen that the first printed layer does not adhere to the base. This may be due to:

Too much height between the extruder and the base

This problem is observed by visually checking this distance, when the 3D printer is making the first layer.

Inadequate base temperature

Certain types of filaments need the base to have a temperature higher than that of the environment, for example ABS. If this parameter is not met, surely this problem appears. Apart from the temperature, there are materials that require an adhesive for the base (DimaFix or Magigoo). Before applying these adhesives it is advisable to wash the base well.

Excessive printing speed

For most 3D printers a first layer speed of 25 mm/s is recommended. If this speed is significantly exceeded, the risk that the first layer does not adhere to the base is very high.

Image 2: Problems with the first layer. Source: Simplify3D

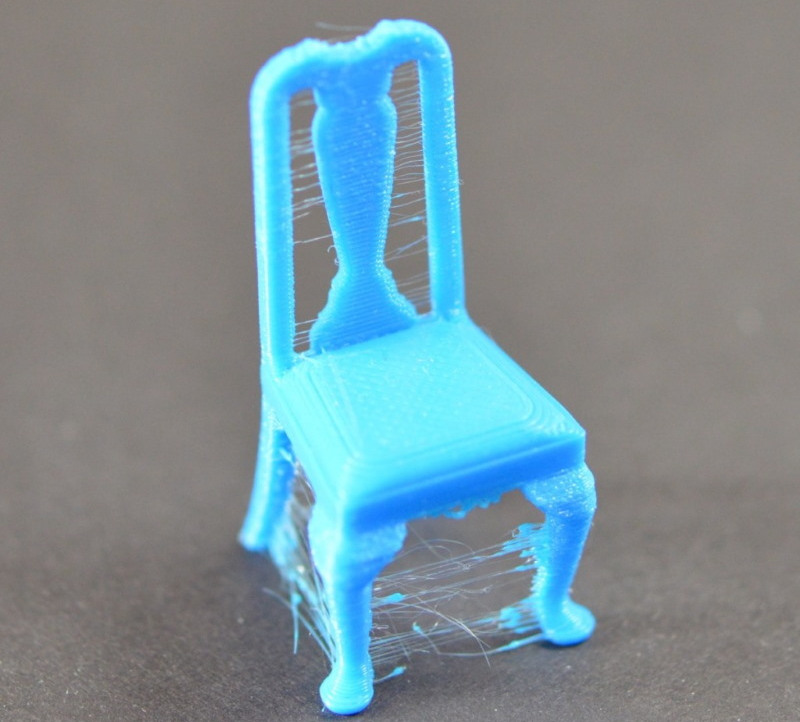

Threads surrounding the piece(s)

It is common to see in 3D prints threads of material surrounding the piece or between the pieces that are being made simultaneously. This error is usually due to parameters linked to the retraction of the extruder:

Insufficient retraction distance

This error is very common in "bowden" systems, where there is a long distance between the extruder engine and the Hotend. This distance varies with the type of material, being 8 mm a good measure to start and increase if the problem persists.

Retraction speed

For this parameter, the size of the piece and the distance between pieces must be considered. If the part or distance is small, more speed is needed to give the extruder motor time to make the filament recoil path. If the speed is excessive, bubbles will be created inside the HotEnd and the extruder pulley will mark the filament a lot.

Image 3: Threads surrounding the piece. Source: Simplify3D

Black dots (charred) on the printed piece

When this printing error is visible, it is because there were filament remains on the outside of the nozzle. These depositions become viscous with the temperature and with the movement of the extruder they are transferred until arriving at the piece that is being printed. These depositions usually occur at the beginning of printing, at the time that the extruder performs in the "home" of the z axis, remains that hang from the nozzle are placed on the outside of it. To avoid the problem, at the beginning of the printing it is necessary to check that this does not happen, and in case it happens, remove the filament from the nozzle with tweezers.

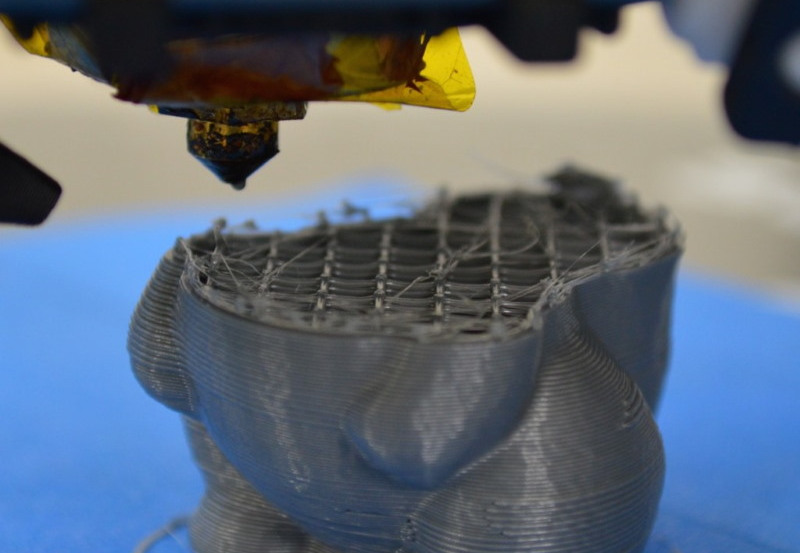

Pieces half done

This problem is one of the worst due to the delay that occurs in the time of printing a piece, and, because it occurs for reasons that are easy to correct. Before starting an impression, ensure that the amount of filament available is sufficient, weighing the filament. A practical tip (small or medium pieces) to approximate the available filament length is to measure the diameter of the rolled filament, calculate its perimeter and multiply it by the number of turns in the coil. Another reason may be that an overlap of the filament occurs, preventing the material from entering the pulley of the extruder motor. Finally, if the tensioner of the extruder pulley does not have enough tightening, the filament will not advance through it, stopping the exit of material through the nozzle.

Image 4: Half-made pieces. Source: Simplify3D

Separation between layers

3D FDM printing works by building objects layer by layer until the desired shape is obtained. If the adjacent layers do not join correctly, the final piece can be broken by joining the layers. This problem may be due to two reasons:

Excessive layer height

During 3D printing of a part, it must be ensured that each layer that is being manufactured presses on the lower layer sufficiently so that the two layers are joined in a resistant way. It can be taken as a general rule that the layer height cannot be more than 80 % of the nozzle outlet diameter. For example, when using a 0.4 mm nozzle, the layer height should not be greater than 0.32 mm. If a separation between layers is detected during printing, it is recommended to reduce the layer height.

Extrusion temperature too low

Once the layer height is verified to be correct, but the separation between layers persists, the problem is in the extrusion temperature. If the temperature reached by the filament is not hot enough, the adhesion with the lower layer will be bad, which will cause it to easily break the piece. For example, thel PLA can be printed at 180 °C but when a user makes parts with high speeds (60 mm/s), the extrusion temperature is not enough for the layers to adhere strongly, so the temperature must be increased at intervals of 10 °C until a good connection between layers is achieved.

Image 5: Separation between layers. Source: Simplify3D

Lack of material between the outer layers and the filling (overlap)

This symptom is easily determined, since you only have to observe the piece with determination a few seconds and see the separation between the outer layers and the filling. To solve it, you must increase the percentage of "overlap", which is usually 15 %, raise it to 20 % or 25 % if you have this problem.

Image 6: Overlap. Source: Simplify3D

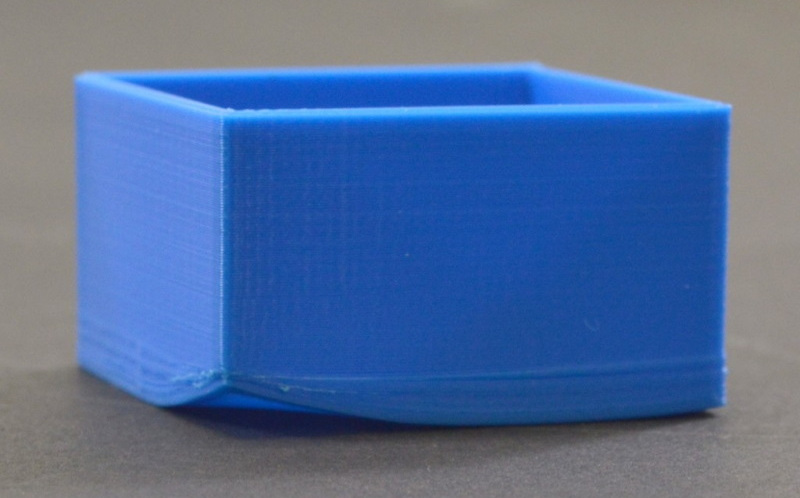

Warping

It is called "warping" to buckling the layers of a piece that are in contact with the base. This buckling is common in materials such as ABS, materials with high extrusion temperatures and which tend to deform as they cool. To avoid this problem, we usually resort to:

Hot print base

Currently most 3D FDM printers have a hot base for printing. For materials sensitive to temperature changes, such as ABS, using a base temperature of 100 - 120 ºC is key to maintaining dimensional stability.

Enclosed

When a user wishes to make parts in ABS of medium or large size, using only a hot base is not enough to prevent warping. In this case the 3D printer must have an enclosed and in case you need to make large volume parts, a heated environment is recommended.

Image 7: Warping. Source: Simplify3D

Gaps between the passes of the last layer

When a poor finish of the upper layer is observed, with an aspect that conveys a feeling of lack of material it may be due to a slightly dense inner filling, with holes that are too large and difficult to cover. Another factor that produces this is an insufficient number of layers after filling, to completely cover the surface. This error may also appear due to insufficient filament flow, especially in large pieces, where continuous passes are large. To check if there is a problem of low flow, a check of external measurements is made, if these are smaller, the flow must be increased from 5 % to 5 % until the part has the design measure.

Image 8: Gaps between the passes of the last layer. Source: Simplify3D

Conclusion

With everything explained above, users of a 3D FDM printer should know how to solve most of the problems that can occur in the day to day of 3D printing.

hola, les comento ya que tengo un problema con mi impresora 3D y espero me puedan ayudar, el problema surge cuando mando a imprimir y a mitad de la impresión, la impresora se detiene y arroja como error impresión pausada, es decir, de la nada se detiene, el detalle es que en tiempo atrás ya había impreso piezas y habían salido correctamente, esto me ha pasado últimamente, sin tener respuesta alguna ni solución, cualquier información seria de gran ayuda. saludos

Hola Daniel, Es probable que se deba a que la placa no es capaz de procesar la inforamación que recibe del BUS (sistema de comunicación SD o cable a PC). ¿Cómo se está enviando el .gcode?

Hola, consulta, tengo una ender 3 y de un momento a otro dejaron de funcionar los ventiladores, los cambie , pero al imprimir cuando llega al 5% se detienen, que podra ser ? saludos

Hola Daniel a mi me sucedio lo mismo en algun momento, y desarme y cambie la placa (aprovechando en poner una placa silenciadora) pero siguio igual, luego me di cuenta que era la microsd, no era compatible al parecer, y con eso solucione mi problema.

Hola! sucede lo mismo en mi Ender 3, de la nada se corta la impresión y me salta el error RESUME.- que al iniciar nuevamente la impresión queda marcada una mala capa en la pieza. Siempre use la MicroSD que vino en caja con la impresora, probare cambiarla y ver si se soluciona.

Amigo, me paso lo mismo, probé de todo y resultó ser más simple de lo que parece...resulta que en el sensor de filamento estaba un poco doblada la ruedita por dónde pasa el pla...la doble para que mantenga presionado el botón

Hola, buen día, hace unas semanas compré una Ender 3 pro, con cama magnética, solo eh imprimido en PLA, funcionado bien, pero solo puedo imprimir si uso una balsa, de otro modo se despega enseguida y arruina la impresión. Cuál puede ser el problema?Si uso una balsa para imprimir, no hay problema, pero consume más PLA, además no me genera los soportes, ya nivele la cama lo mejor que pude, soy nuevo en esto de la impresión 3d, uso el crality slicer porque con el ni un diseño se adhiere

Hola Andrés.

¿Qué producto de adhesión estás utilizando para la base? Te aconsejamos alguno de los que disponemos en la categoría Adherencia a la base.

Hola Andrés te sugiero 1.- Primero nivelar la cama 2.-Reducir al mínimo el espacio que existe desde la cama al extrusor e imprimir la primera capa 3.- usar siempre la cama caliente esto es lo que a mi me solucionó el.problema 4.- usar una habitación que mantenga una temperatura sobre los 15 grados, al enfriarse el material se despega de la cama. 5.- Pulverizar con alguno de los materiales sugeridos la cama antes de imprimir, si no tienes donde comprar usa laca de pelo, es un spray que usan las mujeres para fijar los peinados Respecto a los soportes donde dice soportes, debes configurar: tocando la cama caliente Eso habilita los soportes Y paciencia mucha paciencia Un abrazo

Buen dia! Tengo una impresora con sistema bowden, hace un tiempo que empezo a tener el mismo problema en cada impresión, cuando llega a los 5 mm de altura se tapa y ya no sale mas plastico, que puede ser?

Hola Javier.

Puedes echarle un vistazo a los consejos y soluciones que comentamos en nuestro post Consejos para la impresión 3D: Durante la impresión.

Tengo exactamente el mismo problema, con cualquier pieza, a unos 5mm, 4,5mm para ser más exactos, se aparta el extrusor, vuelve a la pieza y parece que sigue imprimiendo, pero no suelta PLA, se pone a imprimir en el aire sin echar nada, siempre me pasa igual con diferentes tipos de piezas

amigo te recomendaria que buscaras si es un problema con el tubo de teflon de la impresora

Buenos días, tengo un problema al imprimir una base en PVA (que también uso para los soportes tanto internos como externos) y después imprimir en PLA debido a que no se adhiere y al despegarse se arruina la pieza

No sé si te refieres a que el problema de adhesión es entre el PVA y la base o entre el PVA y el PLA. Si el problema está está en la adherencia entre el PVA y la base puedes solucionarlo fácilmente usando algún producto para mejorar la adhesión como los que tenemos disponibles en nuestra tienda: https://filament2print.com/es/229-adherencia-base Si el problema es la adherencia entre el PVA y el PLA, la cosa es más compleja. El PVA y el PLA no tienen buena adherencia entre sí, y esta empeora a medida que el PVA se hidrata. Te recomiendo que sitúes la pieza de PLA directamente en contacto con la base y uses el PVA sólo para los soportes. Si aún así quieres imprimir una base de PVA entre la pieza de PLA y la base, asegúrate de que el filamento de PVA esté en las mejores condiciones y no haya captado humedad.

Bonjour, J'ai une imprimante 3D Tevo Tornado avec un buse de 0.2mm. J'ai des séparations au niveau de mes couches d'impression à certaines hauteurs (toujours aux mêmes niveaux) ce qui fait que mes impressions cassent facilement. Ce problème est présent même si j'imprime avec un hauteur de couches de 0.1 mm ou 0.15 mm inférieur à 80% du diamètre de la buse comme indiqué plus haut. J'ai nettoyé mon axe Z et mis de la graisse mais ceci ne change rien à mon problème si vous avez une idée. Je vous remercie d'avance de votre réponde et prenez soins de votre santé :)

salut j'ai le même problème que toi, à tu trouvé une solution ? merci !

Il s'agit probablement d'un problème d'adhérence entre les couches. Pour améliorer l'adhérence entre les couches, vous pouvez essayer d'augmenter la température d'impression de 5 à 10 ºC et d'augmenter l'épaisseur de la paroi à 1 mm. Si vous utilisez de l'ABS, assurez-vous que le ventilateur de calque est éteint.

estoy haciendo impresiones de mascarillas y me he dado cuenta que al hacer el relleno la impresora se me va de varas y me saca filamento de la figura dejando unas lineas verticales en los laterales de la pieza. Acabo de ponerme el cura y soy un poco inexperto con el (antes tenia el simplify y me iba todo de lujo). Sabriais decirme de algun parametro que pueda causarme este problema? Velocidad, temperatura o algo en la parte del relleno? lo tengo en modo rejilla

Hola Leo, si el problema es que te imprime el relleno por fuera del perímetro, comprueba que el valor de "Porcentaje de superposición del relleno" dentro del apartado "Relleno" sea inferior a 100%. Lo habitual es usar un valor entre 10% y 50 %.

Buenos dias tengo un problema de coordinacion de tiempo de impresion con mi impresora Ender 3 Pro, actualmente estoy usando Simplify 3D para editar la impresion, el problema es que cuando preparo para imprimir el programa de dice por ejemplo 1 hora y 30 min en total....luego cuando imprimi la pieza supera las 2horas.... a que se deberaaguardo si ayuda, desde ya muchas gracias!!!!!!

Buenas tardes, estoy haciendo viseras para pantallas, al principio me salieron muchas bien, ahora no me salen verticales( se inclinan), por lo cual son inservibles. La regule y no mejora. Espero vuestra respuesta com prisa por ayudar. Muchísimas gracias. P.D: las estoy regalando a los hospitales, personas de riesgo...etc.

Hola, me estoy iniciando en esto de la impresión 3d con una geeetech I3 pro w y aunque está calibrada (o eso creo) cuando le doy a imprimir, se me va a media altura y empieza a imprimir la pieza en el aire, a unos 15 cm de la cama ¿En qué estoy metiendo la pata?

Podría ser que en el slicer estás colocando la pieza girandola a horizontal pero no le ordenado después que haga un lay-down o descansar sobre la base y entonces no empieza pegado a la base

Yo creo que en algun momento por error marcaste ese lugar como Home de la impresora, te recomendaria que desde la misma impresora hagas que se mueva hasta la altura que tu quieres, En el caso de la ender 3 con "Auto home" lo hace sola si la armaste bien o sino con "Move axis" lo colocas donde quieres y ahi seleccionas en la impresora que ese lugar es donde se parte la imprecion, denuevo en el caso de la ender 3 esa opcion se llama "Set Home Offsets"

Hola tengo una ender 3 pro y cuando imprimo no hace la pieza completa en el eje Z, la impresora da por terminado el trabajo pero falta por terminar me da la impresion que el eje z se queda estancado en cierto momento aunque si lo pruebo solo moviendo el eje Z sube lo que corresponde. PD: estoy haciendo viseras para mascarillas.

Hola estoy teniendo problemas con la impresion de las primeras capas salen como con ciertos relieves esto empezo a ocurrir desde que cambie mis pololus a unos drv8825 con una ramps 1.6 sera que regule algo mal? Saludos y gracias!

Hola tengo un problema con mi Ender 3 pro, quiero hacer mascarillas pero tengo 2 graves problemas. 1. El objeto cuando lo veo en Cura se ve bien, pero cuando imprime no se ve igual que en cura. 2. Ese mismo objeto cuando se imprime, el relleno no toca las paredes. Ya calibre los 4 puntos de la cama, la temperatura es de 60 - 70°c y de la boquilla a 205°c, Ya corregí los steps/mm para que se mueve y saque de filamento PLA lo que digo. Moví un montón de parámetros y sigue igual, yo moví el overlap que se lo subi a 100% y sigue igual. la verdad ya no se que hacer, p

Buenos días tengo una impresora Prusa i3 prob y no puedo hacer que arranque la impresora esta todo bien conectado pero al momento de encenderla no arrancan la luces de procesamiento de la placa madre.

Tengo una Ender 3 pro, mi problema es que cuando hace la línea de testeo y la finaliza para hacer el viaje al centro de la cama esa línea no la corta como antes y me la arrastra hasta el borde de la pieza eso hace que se me haga una pelota de filamento en la boquilla, estoy imprimiendo ptge y probe con distintos rollos y me hace lo mismo, la cama esta bien nivelada. termine de hacer una pieza y quise repetir y ahí empezó el problema, cambié el tubo de ptfe y me sigue haciendo lo mismo ya hice miles de pruebas y sigo igual con la máquina ya no se que más hacer si alguien me puede orientar para solucionar ese problema.gracias!!!

Ezequiel yo tengo el mismo problema que te sucedió a ti, finalmente conseguiste solucionarlo? de ser así, serías tan amable de compartir con nosotros cómo hacerlo? Muchas gracias

Hola tengo el problema con la impresora 3d dream maker que el error que aparece es interruptor atascado detenido

Hola estoy intentando imprimir filaflex de recreus 82A en una Artillery X1 que es de extrusión directa y lleva un volcano, el problema es que en la pieza sale con porosidad y por mucho que lo intento secar el filamento con una Ebox no lo consigo y necesito que la pieza sea estanca, he probado con varias temperaturas y velocidades y nada, algun consejo gracias

Buenos días Carlos. En primer lugar comprueba que la tensión del tornillo del extrusor sea la correcta. Tanto si la tensión es demasiado alta como demasiado baja, se pueden producir problemas de extrusión con filamentos flexibles. Una vez tengas la tensión correcta, fija el flow de tu impresora entre un 110 % y 120 %.

Hola, tengo Anet A6 y A8. En ambas se me atasca el hotend de un modo tal que no puedo retirar el filamento. Qué puede ser?

Buenos días Jorge, Tanto la Anet A6 como la A8 usan extrusor directo, así que lo primero que deberías comprobar el que distancia de retracción tienes configurada. Debería estar entre 0.5 y 1.5 mm. Si es superior a 1.5 mm prueba a bajarla hasta 0.8 mm.

Hola buenos días, tengo un problema y quisiera saber si me pueden ayudar, tengo una ender3 Y estoy imprimiendo unas piezas pero en la última capa me deja el punto de la boquilla marcada cada vez que termina una línea Y la figura me queda llena de puntos o arrastra La boquilla y me deja marcas en las piezas, Si me pueden ayudar se los agradezco

Buenos días Cristian, En primer lugar, asegúrate de que tienes las retracciones activadas y correctamente configuradas. Si es así, prueba a activar las funciones "Retracción en el cambio de capa" y "Salto en Z en la retracción" en tu software de laminado.

Hola. Gracias por vuestra atención. El caso es que no hace ni seis meses que me propuse aprender a imprimir. He ido mejorando e investigando (en este punto vuestro blog me ha aclarado muchos puntos) pero hay un problema que no se cómo denominar y por tanto no se cómo encontrar la solución. Las capas verticales, empiezo a dominarlas y no me dan problemas, pero las horizontales, algunas, no da relleno suficiente y se ve el borde del filamento. Creo que es algo de configuración, por favor ¿me podéis identificar el problema y darme pistas para solucionarlo? Gracias de nuevo, un saludo. https://subefotos.com/ver/?76e4b2a22663f6708d819db0b96b11efo.jpg

Buenos días Juan, Una solución para minimizar esos huecos que aparecen entre capas es aumentar el número de perímetros y reducir la altura de capa. Reduciendo la altura de capa conseguirás transiciones más suaves en superficies complejas como las de tu pieza y con un mayor espesor de pared reducirás la aparición de esos huecos.

Hola! Yo tengo el problema de los hilos (a un nivel exageradísimo), pero no es la retracción (toqué mil parámetros y nada..) al final hice un test para ver si imprimía lo que tenía que imprimir (midiendo la extrusión del filamento) e imprime más de lo que debe... esto ha sido justo después de cambiar unas piezas del extrusor.. (la rosca dentada es más pequeña) tiene lógica pero... como puedo solucionarlo? Saludos y gracias de antemano!

Buenos días Jorge, Para solucionar el problema debes calibrar el flujo de tu impresora. Puedes echar un ojo a este post en el que explicamos como hacerlo paso a paso: https://filament2print.com/es/blog/33_flow-impresion-3d.html

Hola, tengo un problema con mi Ender 3 y quizás ustedes puedan ayudarme. Espero que sí. Desde hace meses comienza mprímiendo bien, pero pasado un tiempo, o cierto número de capas (un cm de altura o si, depende de la pieza) comienza a fallar. Deja huecos hasta que el plástico deja de fluir correctamente. Espero que me puedan orientar porque empiezo a estar un poco desesperado. Mil gracias por anticipado.

Hola, no vi mi problema aqui y quizas puedan ayudarme. Tengo una ANET ET4 y creando varios modelos planos al mismo tiempo, cuando cambia de un modelo al siguiente arrastra la boquilla por las piezas y hace que se levante el PLA que estaba en la base y lo arruina. Qué podria hacer? cambiar el Z hop de 0.080 a uno mas alto? Gracias

Hola a todos, necesito de su ayuda ... tengo la CR10S5, imprimia bien hasta hace unos días a pesar del problema de la calibración que ya logre ... uffff ... pero ahora tengo el siguiente problem Cuando esta imprimiendo, mas o menos al 50% va todo bien impresiona limpia y todo, pero esta se corre mas o menos 1 mm, como que a cierta cantidad de porcentaje esta se traslapa ... después continua y termina de imprimir bien como nada hubiese pasado ... espero me puedan ayudar ...

Hola Carlos, consulta, como lograste calibrar la ender cr10s5?, te pregunto porque tengo la misma y ha sido un parto calibrar la cama ya que cuando posiciono el nozzel para nivelar la cama en los 4 extremos queda relativamente bien pero el centro se hunde y queda como 1 o 2 mm de la superficie de vidrio

HOLA. Buenos dias. Estoy imprimiendo con PLA y realiza la primera capa de adhesion (balsa) sin ningun problema. Peros seguidamente la pieza no se adhiere a la misma )hace como bolsillos). Probe variar temperatura y no hay cambios. Hay alguna sugerrencia? Gracias

Hola buenos días, tengo una Aneto e10 le cambie la electrónica por una SKR V1. 4, y me da error de fallo de temperatura en el nozle y se baja la temperatura y para la impresora, tengo instalado Marlin 2

Hola.. necesito ayuda... no se adhiere las paredes internas de las externas. Tengo una ender 3 pro, nozzle o.4mm a 215°, altura d capa de 0.2mm. Quisiera lograr cortantes de galletitas firmes y con una sola pared firme de 1.2mm. Uso cura. Ya no se que mas hacer.. Graciad

Buen día mi impresora es una tronxy xy y el problema que tengo es que imprime en el aire ya calibre la cama e incluso revise si tenía perdida de pasos pero no las tiene como podría solucionar ese problema

Hola tengo un problema con 2 ender 3 pro. una la tengo hace 7 meses y en este ultimo tiempo la proximidad entre la primer capa y la segunda es muy proxima y provoca el famoso tac! en el extrusor, una vez que finaliza la zona con el patron de relleno las capas siguientes no tienen este problema. la 2da impresora es mas nueva y tiene el mismo problema pero mas solo que el ruido no lo hace pero la primer capa la raspa toda y por consiguiente las capas proximas hace lo mismo hasta llegar al patron de relleno que se estabiliza y da igual si tiene 3 o 20 capas arriba no vuelve a fallar. noc si es exceso de extrucion o problemas en el eje z o algun parametro que se pueda regular eso . muchas gracias

Hola, quiero saber que causa un problema que tengo, acabo de armar una Ender 3 Pro y cuando imprime al llegar a cierto punto se empieza a mover de donde debería de estar imprimiendo y se estropea la pieza. Que podria ser

Buen día, espero me puedan ayudar. Recién adquirí una Ender 3 Pro la cuál ya arme pero al momento de encenderla no enciende, cabe mencionar que la fuente de energía está a "230", espero me puedan apoyar, literal no la he estrenado por el mismo detalle.

Hola les consulto, tengo una Overlord 3D Dream Maker, tengo el problema que no imprime y tira este error "interruptor X atascado" ya le hice limpieza, calibracion y la volvi a los valores de fabrica, y sigue igual, alguien me podra ayudar si sabe que es ese error? muchas gracias !!

Hola Marcos, me pasa lo mismo, pudiste resolverlo?

Tengo una Cr-10 v3 desde hace unos días, tengo un problema al imprimir piezas con altura de capa 0.2 o menor, empieza a imprimir perfectamente pero cuando le parece deja de extrusor filamento,el motor del extrusor sigue funcionando pero deja de extrusor,con capas de 0.28 va perfecta. Que puede ser? Esta impresora viene con un titán original de red directo

Tengo una ender 3 y mi duda es bastante simple desde un momento para otro se me acelera no se porque ocurre probe con diseños anteriores y nada sigue con lo mismo

Hola tengo una consulta Compré una impresora 3D tronxy x5sa segunda mano pero no me detectar el filamento al tratar de imprimir Sería recomendable cambiar el détector de filamento alguien sabe que podría solucionar este problema Gracias de cualquier ayuda saludos

Tengo una WANHAO DUPLICATOR 4, es nueva, la calibro para que pase una hoja entre la placa y la boquilla, luego imprimo cualquier figura y esta se pandea (warping), labase esta entre 110-120 grados. A que se debera o como lo puedo solucionar

hola tengo una SUNLU S8 cuando imprimo piezas en forma circular me deja goticas de filamento en las paredes , no asi cuando hago figuras cuadaras , me podrian acosejar cual es el problema ?

Buenas tengo una artillery genius, llevo unos días con ella y estoy utilizando cura. El problema es que las primeras capas me salen bien, pero luego las paredes tienen huecos y zonas con goteo (no uniformes), estoy imprimiendo con petg, velocidad baja (30 mm/s) y temperatura de 230, 240, retraccion de 2mm y 30mm/s. La costura también es bastante grande. Alguna ayuda gracias

Hola buenas tardes... Me compre una cr10 max y al nivelar, los ejes z solo suben... No bajan hasta la cama

Hola, tengo una artillery x1 y en la última impresión que estaba haciendo, con suficiente filamento (flexible por cierto), a partir de cierta capa ya no ha extruido más. Vamos, que cuando me he dado cuenta había avanzado unas cuantas capas sin extruir filamento. A parte de llegar a entender qué problema ha podido darse, no sé cómo configurar de nuevo la impresión para que la "reanude" desde donde se quedó. Alguna sugerencia? Gracias!

Impresora ender 3 v2 no carga, se quedo pegada en la pantalla creality y ahi se quedo, ya la desenchufe y continua igual ayuda por favor.

Hola, quería saber si pueden ayudarme. Hace unos días compré un cr10s pro (primera vez que tengo una impresora 3d) al hacer la primera impresión de Prueba que viene con la máquina estaba todo bien hasta casi terminar donde no siguió arrojando filamento y solo hacia la forma en el aire. He intentado hacerla imprimir pero el filamento no sale, solo lo hace si lo empujó.. que puede ser?? Ayuda porfavor

Limpia la boquilla Siempre es ese el problema

Yo tengo otro problema cambie mi boquilla de .4 por .6. Y la última capa se sobre encima las líneas pareciera un excedente. De flujo ya cheque el flujo. Y esta correcto A nivelación. También está correcta. Uso bltouch ya cambie configuración en Cura. Mejora un poco pero sigo con el problema regrese a boquilla de .4 pero el problema sigue. Mi impresora tiene un hot en v6 con un titán

Hola buenas, tengo una Ender 3 e imprimo en PLA. A mi me ocurre que me aparecen arrugas y ondulaciones en las paredes de la figura impresa

Hola Marco. Yo me cambié a un PLA HP de Creality (High Performance) que es de un blanco más intenso y opaco. Tiene un acabado más pro. Pero apareció ese problema que comentas. Ondulaciones en las caras laterales, como si toda la capa se desplazara horizontalmente. No he logrado saber qué es. Si ya lo solucionaste, por favor coméntame.

Hola buen día, espero y puedan ayudarme, tengo una Creality Ender 3 V2, Problema: Poco antes de acabar como un 90% aproximadamente, la impresora lo marca como finalizado, se eleva el eje z para liberar el espacio y saca la cama de impresión para mostrar la impresión ya terminada. Alguien sabe por que sucede esto? Gracias de antemano.

buenas grupo. tengo duda con la artillery x1 imprimi una maqueta que quedo diria en un 95 % bien algunos detalles. pero ahora que imprimo cosas pequeñas con el pla este se levanta de la cama y se enrolla y me jode las impresiones pequenas. la cama esta a 60 y el extrusor a 200 grados. que puede ser soy nuevo en esto. gracias ahora de diseñar ni idea solo bajo archivos de thingiverse

hola todos, tengo el siguiente problema, primero soy nuevo en esto y compre una impresorsa Ender pro 3 que con el filamento de muestra que trajo funciono bien pero al cargarle el nuevo filamento no se pega a la base lo que note y no se si influye es que el filamento de muestra al imprimir quedaba blanco mate y el nuevo queda un blanco brilloso tipo naylon la temperatura que use fue de 220 al inicio y 200 para el filamento y 55/60 para la cama o base y nivele la altura de la base

perdon el filamento que coloque es pla+ gst3d y segun su calco imprime a 180/220°C y la base 40/60°C

Buenas, tengo una Prusa i3 pro w (https://www.amazon.es/GEEETECH-Impresora-bricolaje-200x200x180mm-Aplicaci%C3%B3n/dp/B07PN9XQM3/ref=sr_1_2?__mk_es_ES=%C3%85M%C3%85%C5%BD%C3%95%C3%91&crid=2QPAYVS8ARSFL&dchild=1&keywords=prusa+i3+pro+w&qid=1611505563&sprefix=prusa+i3+pro+%2Caps%2C165&sr=8-2). El problema que tengo es que al intentar calibrar la impresora, el motor del eje Z no se mueve. Los ventiladores se encienden, al igual que la cama, el extrusor y la pantalla LCD. Como es el primer paso de la calibración, no sé si el resto de movimientos funcionan correctamente.

Buenas, tengo una sigmax con doble extrusor el problema es que cuando empieza a imprimir no aguanta ni 2min haciendo el brim y se queda clavada y no reaciona a nada ni se mueve (imprimo con ABS).

Hola! Agradecería mucho que alguien me orientara con el inconveniente que presento. Tengo una Ender 3 Pro, la cual me parece que extruye mucho material; actualmente estoy imprimiendo con PLA, y por si estas pensando lo mismo, ya he calibrado el motor extrusor muchas veces, según el calculo de los pasos, debe tener 340.61 para que ingrese 10cm cuando pido 10 veces que ingrese 10mm, pero bota mucho material, e cambio los bajo a 220 y bota casi lo preciso. ¿Es normal tener que reducir el ingreso de material?

Noté que solo extruye mucho material las primeras capas, ya cuando sigue con las superiores va perfecto.

La solución fue apretar los tronillos en el eje z, estaban sueltos.

Hola mi impresora core xy no me imprime, ni se caliente el extrusor al poner imprimir, como lo soluciono?

Buen dia, acabo de comprar una Ender 3 v2 con cama de cristal, me comenzo a imprimir bien, imprimi un benchy, pero al 90% aproximadamente ya imprimiendo el techo se despego la pieza completa, que puedo hacer para no dañar la cama de crital porosa y se adhiera bien la pieza?

Hola, Jovani, cuando existen problemas de adherencia a la base de impresión, es recomendable utilizar algún adhesivo específico para impresión 3D. En nuestra tienda online, en la categoría "adherencia a la base", puedes encontrar distintos productos. Dos buenas opciones serían 3DLac o Magigoo.

Buen día gente tengo un problema que espero puedan ayudarme. Sucede que tengo una impresora nueva que ya la cambié por la misma razón pero cuando estoy imprimiendo una pieza comienza a hacer un pequeño ruido y es porque el estrusor está saltando. Al final termina haciendo piezas donde no se unen las capas. En principio pensamos que era algo de la impresora pero ya la cambiamos y no sabemos que es.

Hola, Manuel, parece que es algo relacionado con los parámetros de impresión utilizados. Es posible que estés imprimiendo a demasiada velocidad, por lo que el extrusor no puede extruir el filamento lo suficientemente rápido. Prueba a bajar la velocidad sin modificar otro parámetro. Otra opción es que esté relacionado con la temperatura de impresión. Puedes probar a subir la temperatura de impresión.

Hola estoy haciendo un casco y el casco se movio de su base quedo a la mitad muy bien y ya despues no se que paso que se despego de su lugar, porque paso esto

Hola! Por lo que comentas, parece que tienes un problema de Layer Shifting, donde de un momento a otro, la capa queda desplazada y a partir de ahí el resto de la pieza. Esto puede deberse a que estás imprimiendo a una velocidad muy alta. Si es el caso, es posible que escuches un sonido de "clic" cuando el motor no alcanza la posición deseada. Otra opción menos deseable, es que el fallo se deba a problemas mecánicos o eléctricos de la impresora.

Buenas, tengo una impresora 3d labists et4 y me marca mas temperatura de la que esta la cama y el extrusor. He cambiado el holder y sigue con el mismo problema. Que puede ser? Gracias anticipadas

hola tengo una anet et5 y soy nuevo en esto, uso el Cura, grabo el archivo .gcode, lo pongo en la impresora y al iniciar la impresión. Comienza ir de 1% a 100% en segundos, o simplemente al empezar comienza a irse ala izquierda hasta que se traba y tengo que apagarla.

Hola César. Si te pasa con varios archivos gcode, lo más probable es que se trate de un error de firmware o un fallo de la placa. Prueba a compilar y cargar de nuevo MarlinFW, y si el problema no desaparece probablemente debas sustituir la placa electrónica.

Consulta...tengo una Creality cr10-v3, y al usar cura, hace una línea a un lado de la cama y luego comienza a rayar la cama de impresión

Buenas, yo tengo un problema con mi ender 3 pro. cuando mando a imprimir y empieza la tuerca que mueve el filamento hace un ruido como "click" cada segundo y el filamento retrocede un poco y las impresiones salen como sui fueran de pluma bit. nos e exactamente como arreglarlo

Hola! El sonido que indicas puede ser producido por el filamento al saltar hacia atrás un diente del extrusor, debido a que éste no puede traccionar el filamento. Esto se puede deber a distintas causas, como puede ser la temperatura de impresión (relacionada con la velocidad de impresión), algún atasco en la boquilla o la configuración de retracción no es la correcta. Te recomendamos revisar estos puntos para encontrar el problema.

Hola como estan espero puedan ayudarme, hace dias compre una Ender 3 y al armarla ajuste la cama con una hoja de papel como mustra el manual, y mande a imprimir un archivo que biene en la SD imprimio muy bien solo al final quedaron huecos. pero lo que me esta pasando es lo siguiente, al mandar una impresion que diseñe y ajsute ne CURA 4.9 al imprir el borde lo hace bien pero la siguiente capa ya no la hace se tapa la boquilla y en el estructor se queda el filamento atorado y tengo que baja la boquilla para destaparla. mi needle es de .6 y el filamento de 1.7 PLA. gracias de antemano

Hola. Recién acabo de comprar una Artillery Genius y al imprimir figuras, se pueden observar en el contorno de la figura las diferentes capas, es decir, pensé que los laterales de las piezas quedarían totalmente lisas, pero no es así. Es normal?

Hola, hace unos meses empece a imprimir piezas mas grandes, cuando duran mas de 14 horas la pieza se cae, no importa si tiene soportes normales o de arbol siempre se cae, ¿que puedo hacer?

Buenas noches. Tengo una impresora anycubic de brazos, en piezas grandes a mitad de impresión las piezas pierden consistencia y llegan a ser sólo hebras al final de la impresión. Imprimo en pla a 210 grados con la base a 60 grados con velocidad 30. Que puedo hacer?

Hola. Se trata de un problema de HeatCreep, que parece ser bastante habitual en este modelo de impresora. En primer lugar es recomendable que revises el tubo ptfe interno y te asegures que llega hasta el nozzle. A continuación aplica pasta térmica en la unión del heatbreak y el disipador y asegúrate de que el ventilador que refrigera el disipador funciona correctamente. Por último usa la temperatura más baja que te permita el material, si puede ser 195 ºC o 200 ºC mejor. Con esto deberías poder imprimir durante horas sin problemas de atascos o falta de estrusión.

hola . tengo un problema con la impresora que no puedo controlar la temperatura del extrusor .ya que cuando la prendo empieza a calentar el extrusor y no lo puedo detener . es una kingroon kp3s. desde ya gracias

Hola. Acabo de entrar en el mundo de la impresión 3D con una LABISTS ET4, he hecho unas pruebas sin ningún problema pero de repente me aparece un mensaje que dice que cargue más material. El problema que tengo es que hay filamento dentro de la impresora, haciendo un load/unload el PLA fluye sin problema, pero en el momento de imprimir nada más empezar, se para y me aparece el mensaje de que falta filamento. Ya he probado a hacer varios load/unload, desactivado el sensor, ajustado tornillos, reseteado por si era un problema temporal, pero el mensaje sigue apareciendo y no puedo imprimir. ¿Alguna sugerencia? Gracias

Buenos días, tengo un problema con mi impresora hellbot, ya que estoy haciendo un cilindro, con el programa Cura, y antes de la costura se pierde el filamento, modifique en la parte experimental- habilitar deposito por inercia así también, Volumen de deposito por inercia y sigue haciéndolo. Cambie temperaturas, velocidades y sigue. Me ayudan Por fa. Gracias!

Buenas tardes. Tengo una impresora WANHAO Duplicator I3 Mini. Estoy teniendo problemas con las impresiones que se paran poco antes de terminar el trabajo y en algunos casos, no siempre, aparece el mensaje NO SD, es decir deja de ver la tarjeta. Apago y prendo y ya la ve de vuelta.

Hola, Daniel. En este caso te recomendamos que contactes directamente con el proveedor de tu impresora 3D por si fuese un fallo del dispositivo.

Muchas gracias!

Hola, buenas tardes. Tengo una Magna Dual.. Venia imprimiento normalmente hasta hoy, cambie de filamento PLA comun, puse un ECOFILA y tengo el problema que no tracciona. Ajusto el engranaje de traccion, funciona un rato y vuelve a patinar. La temperatura de material es la que indica el proveedor. Si alguien puede ayudarme lo agradezco.

Hola, Ignacio, nunca hemos trabajado con este modelo de impresora 3D, por lo que te recomendamos contactar con el fabricante de tu impresora para que te pueda dar soporte y solucionar el problema.

Hola tengo una impresora biqu b1 y me pasa que estoy haciendo una pieza normal y de la nada comienza a hacer una linea en cualquier lugar y la llena de filamento y no para a menos q la detenga manual, q puede ser

Hola, Leo, nosotros no trabajamos con esta impresora. Por lo que indicas, podría ser un problema de software, de todas formas, te recomendamos contactar con el fabricante para que te pueda dar soporte y solucionar el problema.

Buenas noches! Me compré una magna 2 230 y empezó imprimiendo bien, pero de repente ahora imprime muy fino. Hay mucha diferencia a 0,1 mm. Además se hacen pelotas de plastico. Baje la velocidad y ahí masó empezó a imprimir bien pero sigue muy fino. No sé que sera

Hola, Ezequiel, es posible que tu extrusor esté atascado y por eso sale un hilo muy fino del nozzle. Prueba a sobrecalentar en 10 - 15 ºC la temperatura recomendada para ese material y extruye filamento. Para evitar atascos, recomendamos utilizar filamento de limpieza después de cada impresión. Un saludo!

saludos amigo acabo de comprar mi primera impresora ender3 pero no e podido hacer ni la impresión de prueba lo que le doy a imprimir solo me imprimé lo que quiera no lo que yo le pongo qué puedo hacer gracias

Buenas noches, como les va? tengo un problema recurrente hace un mes. Ya no sabemos con que intentar. Les comento, nuestra ender 3 pro no obedece al comando para el cambio de filamento, por lo que lo hacemos mediante diferentes gcodes (uno para cada color). Hasta hace 1 mes atras funcionaba perfecto despues de 7 meses de uso diario, pero ahora cuando haces un cambio de color sale desfasado. Ya probamos ajustando las correas, las excentricas, limpiandolas y actualizando el marlin. Ya no sabemos que hacer, se agradece la ayuda! pd: Los mismos gcodes son utilizados en otras impresoras y salen bien.

Mi artillery genius no imprime bien, al empezar va todo bien pero al cabo de un rato se empieza a imprimir un poco más atras y luego mas alante, he probado todo pero no logro solucionarlo, soy nueva en impresión 3D.

Hola, yo tengo un problema con la impresión en Petg, que ya me ha sucedido dos veces, al terminar la impresión la pieza está tan pegada en ciertos lugares que cuando la intentó sacar terminó arrancando parte de la base de la cama, ya me ha pasado con la base de la cama original, compré una magnética y en la segunda impresión que hice me pasó exactamente lo mismo

tengo una magna 1 .. el tema es que de repente, las paredes de la pieza no se unen entre si.. probe con diferentes tamaños de paredes, y de relleno pero siguen sin unirse..cuales serian los posibles problemas o soluciones ?

Buenas noches, tengo una impresora magna 2 300... Venía imprimiendo bien hasta que al hacer una pieza más compleja y alta (un elefante), a mitad de la impresión empezó como a debilitarse la salida del filamento y quedan como finos "pelos"... Probé de todo y siguen saliendo mal... Ayuda!

Hola! ¿Qué material estás utilizando? Todo apunta a un atasco del filamento. Puedes probar aumentando la temperatura de impresión y reduciendo un poco la velocidad.

Hola que tal tengo una biqu b1 estaba imprimiendo bárbaro y de la nada no mantiene la impresión en la cama me la levanta y ahora me imprime desfasada la impresión que podrá ser gracias

hola tengo una impresora FLSUM i3 plus . Tengo el problema que pierde la ubicación con la cama. Esto creo sucedió cuando tubo un arrastre en una impresión fallida ya que antes imprimió perfectamente. no se a que atribuirle el problema. los ejes están en la dirección correcta. Esto lo aclaro porque, solo toque la polea para desarmar y reforzar la estructura de sostén de la cama.

Hola, como estas? Mira yo tengo una ender 3 pro, en un comienzo imprimía super bien pero ahora, cuando hago una impresión, todo arranca super bien pero en un 40% o 60% de la pieza la boquilla queda pegada a la pieza, se traba y deja de imprimir. Te agradezco me orientes. Feliz día

Hola, tengo una ender3 pro que casi siempre en impresiones de 6 horas a las 4 horas más o menos deja de extruir por traba del filamento en el carretel, he probado con diferentes marcas siempre PLA o PLA+. Tampoco logró recuperar las impresiones porque parece haber un movimiento hacia arriba en el eje Z que no figura en el G-code

Hola, Enrique, existen algunas bobinas de filamento más propensas a sufrir solapamientos. Nuestro filamento PLA premium tiene un embobinado cuidado que minimiza este riesgo, si bien es importante que, cuando manipules la bobina, sujetes siempre el extremo del filamento para que no se destense. En cuanto al movimiento en el eje Z, probablemente se deba a que la impresora "sigue imprimiendo" sin filamento, por lo que sigue su curso según el Gcode.

Hola buen día, yo tengo una biqu b1 y el problema que me está pasando es que tarda más que lo que dice el problema, yo utilizo el cura cuando mando a imprimir dice que va a tardar 10hs por ejemplo, y la impresora lleva 11hs imprimiendo y va por el 60% no encuentro que a alguien más le haya pasado, que puede ser? desde ya gracias

Hola, Christian, esto puede deberse a tiempos relacionados directamente con el equipo de impresión. Es decir, el tiempo que tarda la impresora en calentar el extrusor o la base de impresión entre otras cosas.

hola buenas noches tengo un problema soy nueva en esto pero la maquina me esta imprimiendo torcido es decir que arranca tocando en una punta y en la otra lo hace en el aire tiene nivelacion automatica pero me lo hace haci que puedo hacer