A team of students from the AGH University of Science and Technology has developed a project in which electric motorbikes are built, promoting electromobility and testing innovative solutions and manufacturing methods such as desktop SLS 3D printing.

From the university laboratory, full of industrial machines, the student team builds the electric motorbikes from scratch. Some of the necessary parts are made by hand. Others are made by machining with specialised tools. However, some of the parts do not conform to these manufacturing methods and are made using 3D printing.

Not all parts can be printed on all printing technologies. This may depend on the geometry, material requirements or characteristics of each part. Thus, the student team found that the best option for manufacturing the radiator housing was to use selective laser sintering (SLS) technology, due to the variety of materials that can be used in this manufacturing technology, the precision and durability of the parts.

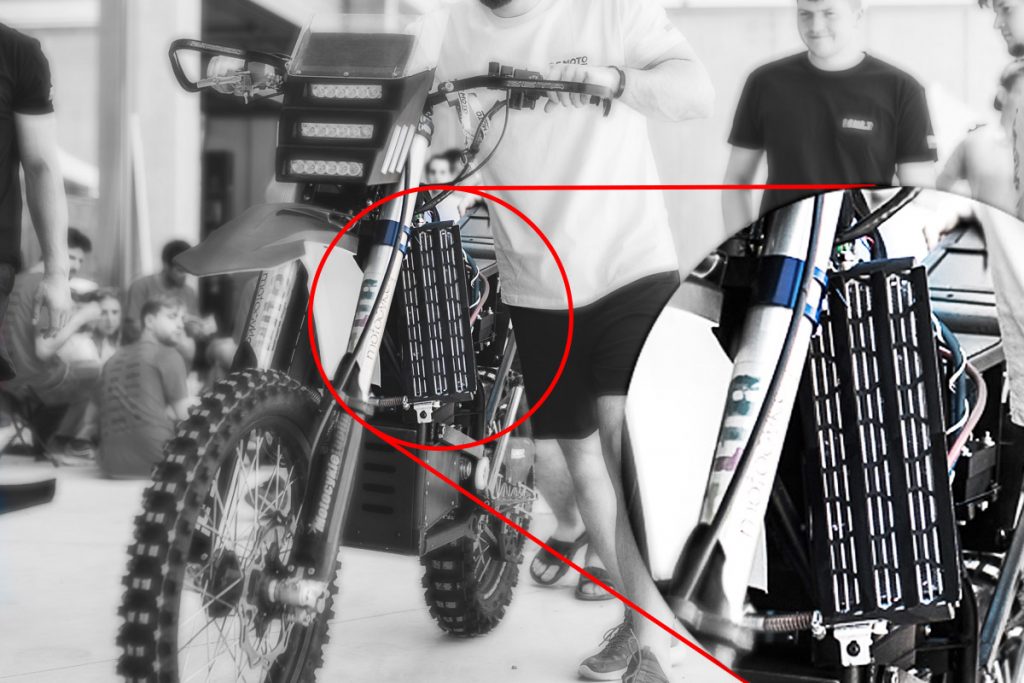

Image 1: Radiator casing 3D printed using SLS technology. Source: Sinterit.

To make these parts, the team of students used a desktop SLS technology 3D printer: Sinterit Lisa Pro. One of the advantages of this technology is that it allows the fabrication of complex designs without the need for supports. In the case of the radiator housing, it was designed with a honeycomb structure, and air deflectors were included to prevent the radiator from getting stuck in mud or destroyed by gravel.

After the assembly of the part, the team carried out several tests and submitted their project to the Smart Moto Challenge in Barcelona, a competition in which each team plays the role of a motorbike manufacturer who must launch their motorbike within three years. The competition commission verifies each project through documentation and various tests.

The two electric motorbike models developed by the AGH student team passed all the tests and, although the bike had several crashes, the SLS 3D printed part was not damaged.

Image 2: Project developed by the AGH student team. Source: Sinterit.

Prototyping for the automotive industry requires precise manufacturing technologies that offer durability and repeatability. This is why selective laser sintering (SLS) is the first choice of many R&D teams and manufacturers.

Thanks to the development of desktop SLS 3D printers, SLS 3D printing has become an accessible 3D printing technology for small companies, research centres, universities, etc. Thanks to these 3D printers, it is possible to manufacture prototypes and even small runs of professionally finished products.