No products

Product successfully added to your cart

0 products in the cart 1 product in the cart

PP3D is the polypropylene (PP) filament that Recreus and Repsol have jointly developed. This synergy results in high quality polypropylene thanks to Repsol's contribution and experience in the manufacture of polyolefins.

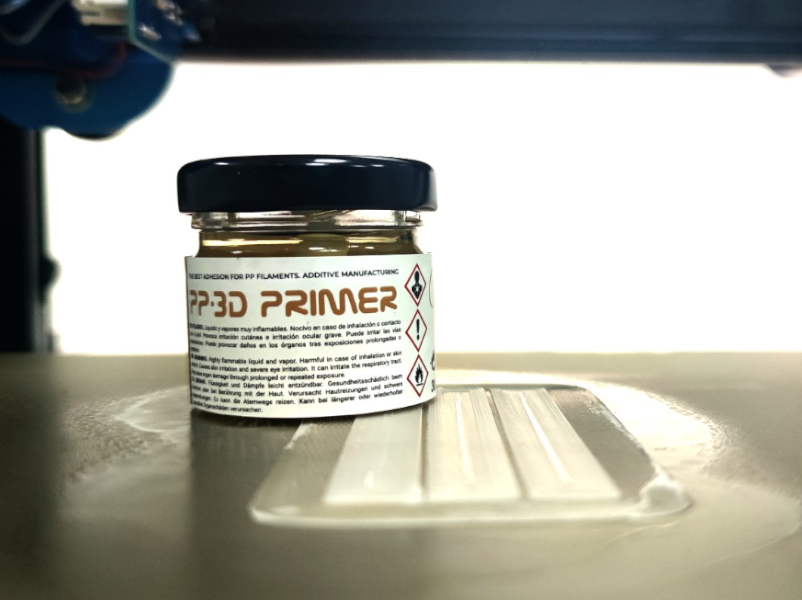

One of the most outstanding characteristics of this product is that the filament is accompanied by a primer to be applied on the printing base; achieving the adhesion of the filament to the printing base at only 40 ºC.

Image 1: The PP3D primer. Source: Recreus.

PP3D filament

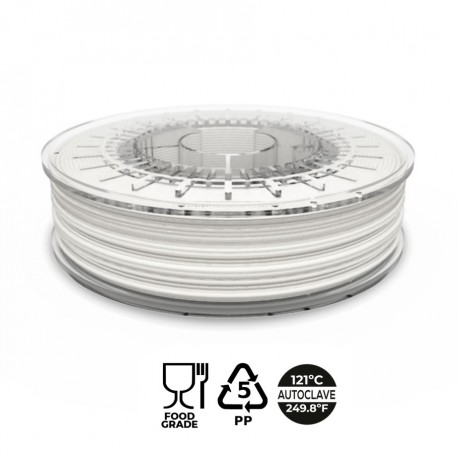

The PP3D polypropylene filament is available in two colors: Black and Natural; and in two diameters: 1.75 mm and 2.85 mm.

The PP3D filament has a high level of resilience, high impact resistance, exceptional fatigue resistance, high levels of toughness and a low coefficient of friction. It's also resistant to a wide range of acids and bases. Its finish is matte, similar to that resulting from the injection process, concealing the union of layers until it's almost imperceptible.

The advantages of this filament do not end there, since it has a food grade certificate, making it suitable for contact with food. The Natural color PP3D filament has an added feature, and is that it can be autoclaved at 121 ºC .

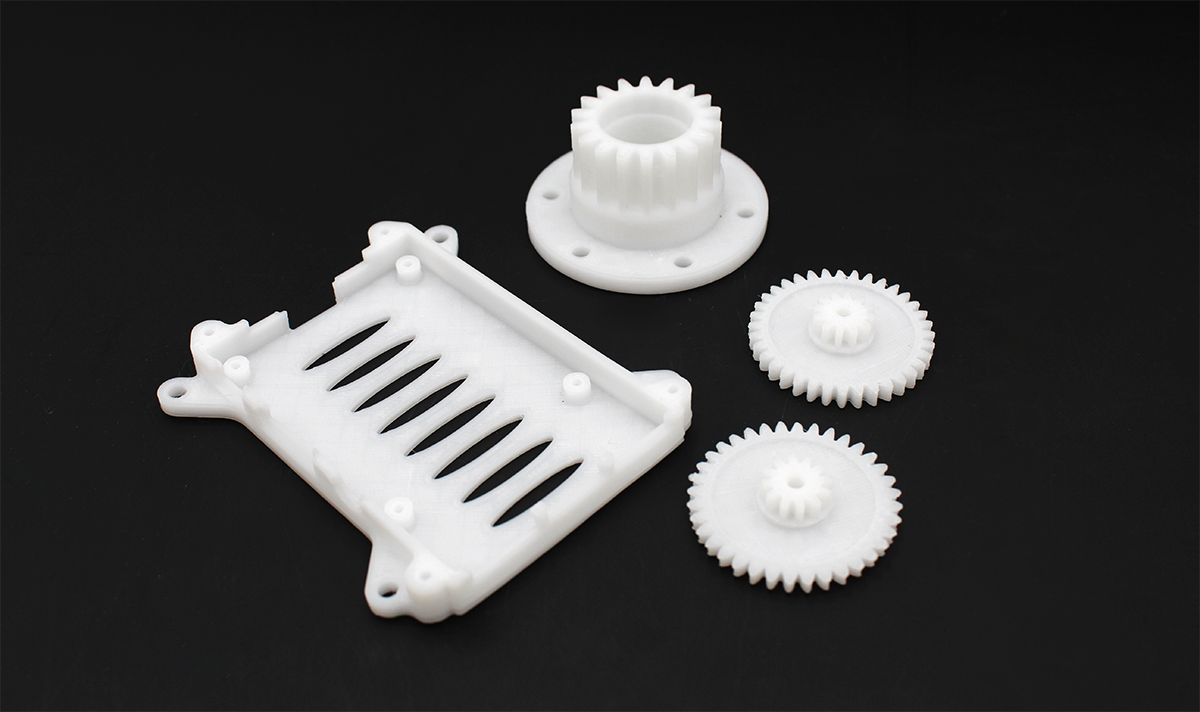

Image 2: Pieces printed with the filament + PP3D primer. Source: Filament2print.

All these properties make the PP3D polypropylene an ideal material for both prototyping and the manufacture of resistant and light final parts, due to its low density.

At the time of printing, the PP3D polypropylene filament stands out for its good adhesion between layers and for the ease of printing compared to other polypropylene filaments that have a high level of warping. This decrease in warping is achieved thanks to the use of Primer, which provides a strong and immediate adhesion to the printing base.

PP3D Primer

The PP3D polypropylene filament spool is accompanied by a jar of primer. This primer must be applied to the printing base before each use so that the printing result is optimal. It should be kept in mind that both products (filament + primer) have been developed to be used together, so the use of one without the other can lead to failed prints.

At the end of a printing session with the PP3D filament, the Primer can be removed from the printing base in a simple way, heating the hot bed of the printer to 85 ºC to be able to peel off the primer layer. If you want to make more prints, it must be taken into account that the same primer layer can be reused in up to 3 consecutive printing sessions, with large and small pieces. The primer is heat activated, so the same application can be reused for several prints if the bed is not cleaned between printing sessions.

It is therefore recommended to group 3D printing sessions with the PP3D filament to get the most out of the primer. This way, the user can save on primer consumption. Another important thing to keep in mind is that the primer should only be applied to the surface that the piece will occupy, not the entire build plate.

Following these tips will ensure that the primer jar will last for the entire spool of the PP3D filament.

Video 1: Introduction to PP3D. Source: Recreus.

Applications of the PP2D filament + primer

The PP3D filament + primer allows a multitude of applications in different sectors of the industry. The most outstanding applications are:

- Bottles and containers: The chemical resistance of the material makes it ideal for this type of application in the form of functional prototypes that may contain a liquid product.

- Parts that require low friction and heat resistance.

- Equipment for electrical and electronic safety: the high electrical resistance makes this material a good insulator.

- Prototypes of industrial tools and parts: Due to its good mechanical properties.

- Parts that must be resistant to salts, acids, solvents, greases and oils.

- Mechanical components.

- Parts that require sealing: PP3D filament allows the manufacture of hermetic products.

Thanks to the development of Recreus and Repsol, the user can enjoy the advantages of 3D printing polypropylene pieces in a relatively simple and effective way, reducing the warping that usually accompanies printing with polypropylene filaments.

| Impact strength (KJ/m2) | 50 |

| Flexural modulus (MPa) | 800 |

| Softening temperature (ºC) | 61 |

| Sealing | Sealing |

| Lightweight | Lightweight |

| Alimentary use | Alimentary use |

| Hide color variations | (Hide color variations) |

.png)