3D printing is already in the mouth of everyone and the vast majority of people are generally aware of the advantages it brings, both in the daily life of a particular user and a professional user, but what is not so well known is that there are machines that can complement this technology. In this case we will talk about laser cutters.

3D printers and laser cutters are totally different machines and perform opposite jobs, but at construction level they are similar. A 3D printer uses the raw material with a different shape to the final piece (filament, pellet, resin, etc.), to obtain an object in three dimensions. In contrast, a laser cutter needs the raw material with the same shape and larger size (wood sheet, steel, etc.) than the final piece, and can only operate in two dimensions. The advantage of laser cutters (professionals), is that they can work with an infinity of materials, especially metals, at high speeds.

Image 1: Metal laser cutting machine. Source: Lasercutting

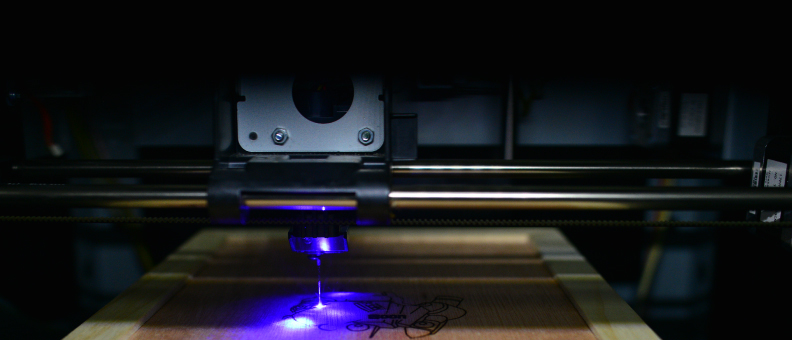

The laser cutter is a machine that uses a system of rails to move a head, where it locates the laser, which can cut metal materials and other types of materials, such as wood or leather, all with thicknesses of up to 6 mm. At an industrial level, the use of laser cutters is very widespread, since they offer easily reproducible results with really narrow slot widths, and small radius holes and curves. In general, it provides value in complex flat pieces, which, in general, would be much more expensive with another type of manufacturing process. In addition, these machines can work at very high speeds without losing accuracy and even with a perfect surface finish, free of burrs.

Within the laser cutters there are two types, depending on the laser they use: CO2 laser and laser diode (Mr Beam II). The CO2 laser works by Carbon Dioxide and other concentrated chemical elements inside a glass tube where two diode bars generate the laser beam. The disadvantage of this type of laser is the width of the laser and its short operating life (1000-15000 hours). The laser diode has an operation similar to an LED but very high power and where all the light is concentrated in one point. They are much more accurate than CO2 lasers and their life is very high.

At the professional level, but in non-industrial sectors, there are laser cutters such as Mr Beam II, which offer the possibility of cutting and engraving a large quantity of materials. In this specific case, this cutter has a 5W class 1 laser head, inside a metal casing with a safety cover and with a fume extraction and filtering system. All this, we must add the lid camera to facilitate the placement of the design you want to cut or burn, and its connectivity through WLAN.

Image 2: Mr Beam II laser cutter. Source: Mr Beam

Currently, there are also 3D printers on the market that can perform engraving work on certain materials such as plastic, wood, leather, cardboard or paper. This is the case of the 3D FDM XYZ Da Vinci Pro Series and Da Vinci Color Series. To make both printed pieces and to record certain materials, these printers have two interchangeable heads, thus concentrating two manufacturing processes increasingly demanded.

Image 3: XYZ Da Vinci 1.0 Pro. Source: XYZ Printing

A laser cutter increases the production power and expands the work field of a 3D printer user, thanks to being able to complement printed pieces with pieces cut or laser engraved, such as making the structural part of a model with a printer 3D and then join the parts of much detail cut by laser. This saves time and manufacturing cost, achieving a great final finish.

Great content. Please keep posting. I'm looking to buy a laser engraver from OMTech(https://omtechlaser.com/) and would like to learn about laser engraving machines.

Thank you very much for your comment. We are glad that you find the content interesting and useful :)