The Virtual Foundry is an American company which, after years of research, has managed to develop the range of metal filaments Filamet™. These filaments, by means of post-processing based on sintering, make it possible to obtain completely metallic parts.

In this way, The Virtual Foundry has become the pioneer and maximum reference in 3D FDM metallic printing.

What are Filamet™ filaments?

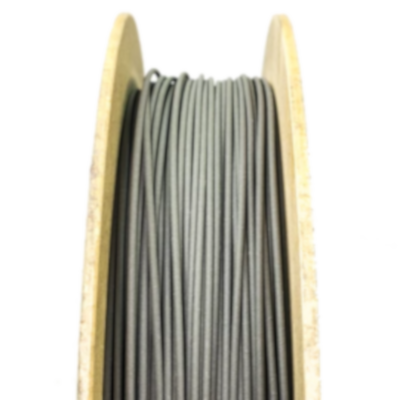

The filaments Filamet™ are made up of a base metal and a biodegradable and ecological polymer (PLA). These filaments include high percentages of metal particles in their composition. However, by using PLA as a binder, they are extremely easy to print on, as their printing properties are similar to those of PLA, allowing any user of a 3D FDM printer to create parts with these filaments.

Video 1: What is Filamet ?. Source: The Virtual Foundry.

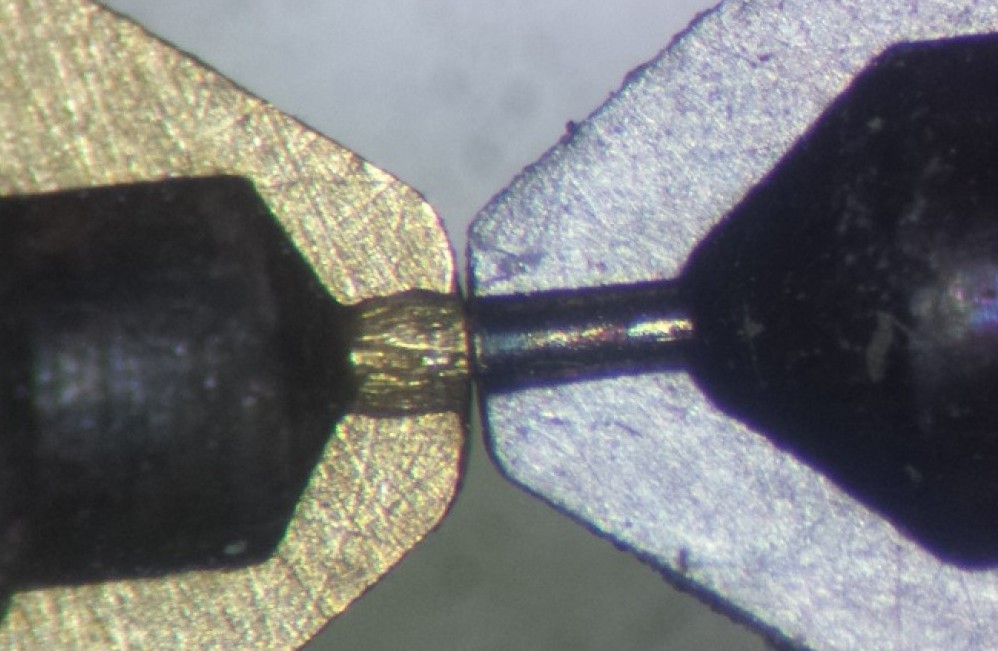

Most of the metallic filaments on the market contain a minimum percentage of metallic particles, around 30%; therefore they are usually developed for decorative purposes only. However, the pieces printed with filaments Filamet™, once sintered have the properties of the corresponding base metal.

An example of this would be the filament Filamet™ Copper: A piece printed with Filamet™ Copper will not have conductive properties until it has been subjected to the disintering process.

Image 1: Cones made of Filamet™ made of un sintered and sintered high carbon steel. Source: The Virtual Foundry.

The result after the sintering of the 3D printed piece will be a totally metallic piece, something unthinkable until now within 3D FDM printing. Thus, with Filamet™, properties similar to those possible with DMLS technology are achieved, but with certain limitations.

Due to the need to sinter the parts printed with this filament, where PLA is eliminated, the parts will have:

- Certain porosity

- Volume loss

- Non-isotropy

Video 2: Density of Filamet filaments. Source: The Virtual Foundry.

At present, Filamet™ has the following filaments:

- Stainless steel 316 L - 80 % metal particles + 20 % PLA

- Bronze - 80 % metal particles + 20 % PLA

- Copper - 90 % metal particles + 10 % PLA

- 6061 aluminium - 65 % metal particles + 35 % PLA

- High carbon steel - 75 % metal particles + 25 % PLA

- Tungsten - 95% metal particles + 5% PLA

Features of Filamet™

The density of the filaments Filamet™ is much higher than that of standard PLA, due to the high content of metallic particles and the density of the individual metals involved.

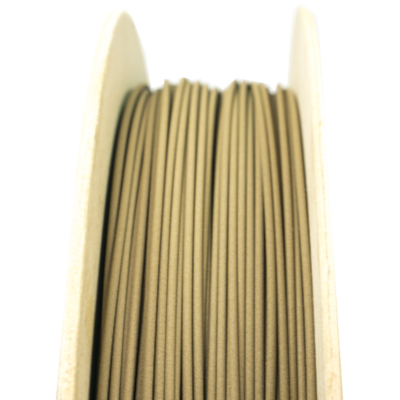

When printing with Filamet™ filaments, it is recommended to use a hardened steel nozzle because of the high percentage of metal particles contained in the filaments. In addition, depending on the material, a nozzle with at least 0.6 mm outlet diameter should be used to avoid clogging. Except for the filament Filamet™ of Tungsten, which allows the use of a nozzle of up to 0.3 mm outlet diameter; and the filament Filamet™ of High Carbon Steel, which requires the use of a nozzle of at least 0.8 mm outlet diameter.

Image 2: Brass nozzle vs. hardened steel. Source: E3D.

Another consequence of the high metallic particle load of these filaments is a greater fragility of the filament before being melted, since they have very small percentages of binding polymer in their composition. However, thanks to the permanent research and development carried out by The Virtual Foundry, this fragility is less and less in its filaments; as can be seen in the following video:

Video 3: Fragility of Filamet filaments. Source: The Virtual Foundry.

In the process of printing filaments Filamet™, it is very important that the filament is as straight as possible before entering the extruder, but these filaments have a certain curvature due to the winding. To solve this, The Virtual Foundry has a Filawarmer, a device formed by a cylinder that heats the filament and a temperature controller.

Image 3: Filawarmer placed inside a filament coil. Source: The Virtual Foundry.

This device must be placed vertically, inside the coil, with the input as close as possible to the filament coil and the output aligned with the input hole of the extruder. The Virtual Foundry recommends hanging the heating cylinder to allow the coil to rotate freely.

Video 4: Filawarmer. Source: The Virtual Foundry.

As the material passes through the heating cylinder, it loses its curvature and increases its flexibility; reducing the tensile strength to prevent breakage and facilitate printing.

When printing with filaments Filamet™ their excellent adhesion to the base must be taken into account. This is such that it is recommended that Blue Tape be used to avoid damaging the printing base when removing the printed pieces.

Sintered of Filamet™

Once removed from the impression base, the parts must be sintered to obtain a full metal part. Through this process the PLA that forms part of the filament is removed. Until this process is carried out, the pieces will not have the properties of the base metal that makes up the filament used.

Video 5: FAQs Filamet. Source: The Virtual Foundry.

Sintering is a process of manufacturing solid parts from an object formed by compacted metal powder, to which a heat treatment is applied at a temperature below that of fusion, but high enough to bind the metal particles together in a resistant manner, resulting in a totally solid block.

Sintering can be carried out in an open environment oven or in a vacuum or inert environment. In our post How to achieve all-metal parts with FDM printing you can see more about sintering and the different ovens that can be used to carry out this process.

If you do not have a furnace that meets the requirements for sintering 3D printed parts with filaments Filamet™, you can contact us and we will inform you about the feasibility and conditions of sintering in our facilities.

Post-processing of Filamet™

Once the filament-printed piece has been sintered with the filament Filamet™, it can be post-processed by sanding and polishing the surfaces as would be done with a metal piece. It is recommended to use a water sandpaper to reduce the printing lines and other small deformations, and to use a finer grain sandpaper each time.

Finally, you can use a rotating tool with a polishing disc and apply polishing paste to obtain the desired shine. Depending on the base metal of the filament, the parts resulting from sintering can be ground, smoothed with heat and even welded.

The filaments Filamet™ of The Virtual Foundry allow, for the first time, to manufacture completely metallic parts through 3D FDM printing, requiring relatively simple post-processing.

This is a very important and useful breakthrough for different sectors of industry: 3D printer manufacturers, biomedical innovation, jet engine development, radiation shielding, space exploration, nuclear energy, dental, artists or fashion design.

I would like to use your filament SS 316 L . I have a Da Vinci Pro 3 in 1 3d printer and Ender 3x pro. It is possible to use it in this models? How much it cost to México, Tlalnepantla. Postal code 54190? Thanks a lot of