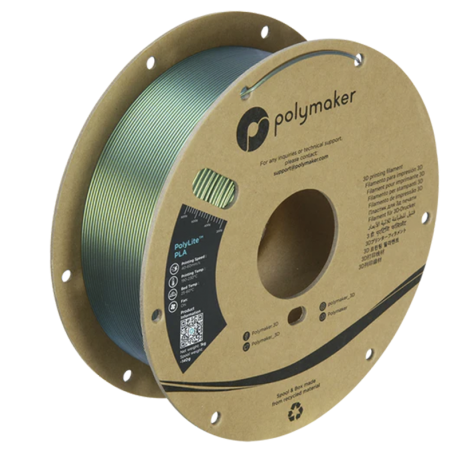

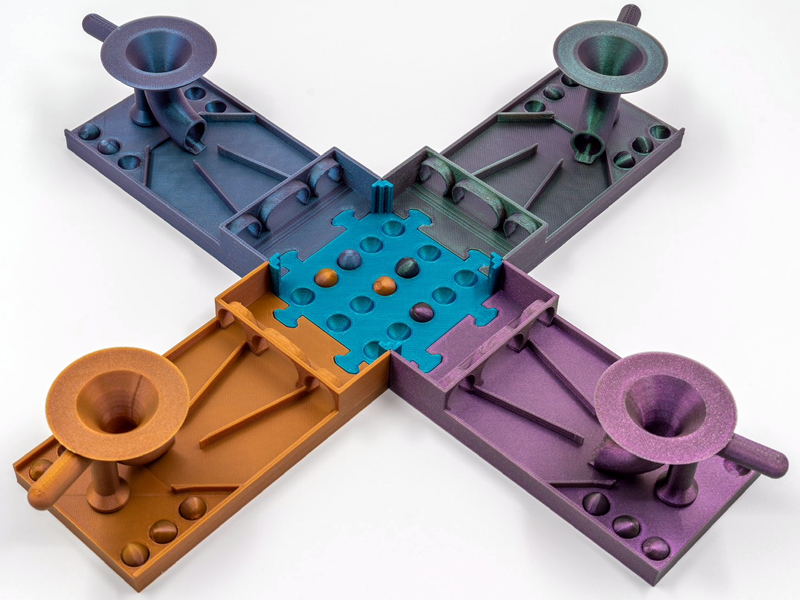

The Starlight PLA filament from Polymaker's family of easy to print PolyLite filaments comes in stunning color options that create a color-changing effect depending on the light reflection. This effect is achieved via a manufacturing method called coextrusion. What's more, the shimmering effect of the filamet is achieved through the addition of very fine powder that is not abrasive and does not jam the nozzle.

PolyLite is a family of 3D printing filaments developed by Polymaker and manufactured with the best raw materials (polylactic acid) to offer exceptional quality and reliability. PolyLite covers the most popular 3D printing materials to meet everyday needs for design, non-functional prototyping or decorative uses. If enhanced mechanical properties are required, Polymaker's Polymax PLA filament is recommended.

PLA is one of the most common materials in the world of 3D printing thanks to its ease of printing, good results and wide range of colours. In addition, PLA does not emit fumes or noxious odours when 3D printed and is very user-friendly due to several factors:

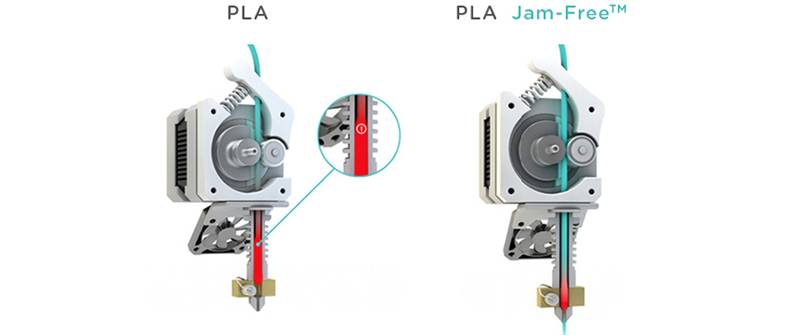

In addition, thanks to Polymaker's patented Jam-Free technology, Polylite PLA significantly improves thermal stability by increasing the softening temperature, resulting in a jam-free filament.

The packaging in which Polymaker presents its filaments is highly studied and carefully designed to preserve the quality and condition of its filaments. In this case, PolyLite PLA is presented inside a vacuum-sealed bag together with a desiccant sachet to prevent the filament from absorbing moisture. This bag is self-sealing, so once the filament has been used, it can be put back into the bag. In addition, all of this is enclosed in a high quality printed box, to avoid knocks and breakages during shipping.

General information |

|

| Material | PLA |

| Format | 1 kg |

| Density | 1.17 g/cm³ |

| Filament diameter | 1.75 mm |

| Filament tolerance | ±0.05 mm |

| Filament length | ±355.3 m |

Printing properties |

|

| Printing temperature | 190-230 ºC |

| Print bed temperature | 25-60 ºC |

| Chamber temperature | ✗ |

| Cooling fan | ✓ |

| Recommended printing speed | 40-60 mm/s |

Mechanical properties |

|

| Charpy impact strength | (ISO 179) XY: 2.7 ± 0.2 kJ/m² / Z: - KJ/m² |

| Elongation at break | (ISO 527) XY: 1.9 ± 0.2 (%) / Z: - % |

| Tensile strength | (ISO 527) XY: 46.6 ± 0.9 MPa / Z: 43.5 ± 3.1 MPa MPa |

| Tensile modulus | (ISO 527) XY: 2636 ± 330 MPa / Z: - MPa |

| Flexural strength | (ISO 178) XY: 85.1 ± 2.9 MPa / Z: - MPa |

| Flexural modulus | (ISO 178) XY: 3283 ± 132 MPa / Z: - MPa |

| Surface hardness | - |

Thermal properties |

|

| Melting temperature | 150 ºC |

| Softening temperature | (ISO 306) 62.9 ºC |

Specific properties |

|

| Transparency | - |

Other |

|

| HS Code | 3916.9 |

| Spool diameter (outer) | 200±1 mm |

| Spool diameter (inner hole) | 55±1 mm |

| Spool width | 65.6±2 mm |

Although the ideal printing temperature of PolyLite PLA may vary for each 3D printer, the ideal printing temperature is between 190 and 230 ºC. If a heated bed is available, it is recommended to use the bed at a temperature between 25 and 60 °C.

It is advisable to use the layer fan. Because of this it is important to adjust the ideal temperature depending on the extruder used. PolyLite PLA filament is suitable for any type of nozzle. In terms of printing speed, it is advisable to print at around 40-60 mm/s, although it is possible to print slower for 3D prints with a better finish.

PolyLite PLA filament is moderately hygroscopic. In case the filament contains more moisture than it should, it is recommended to dry the filament in a dedicated drying machine such as the Print Dry Pro filament dryer for 6 hours at 55 ºC.

Moisture can cause errors and even failed 3D prints. To avoid it at all times and not require the use of a filament dryer, it is recommended to use Polybox during the entire printing process and then store the filament in the self-sealing bag provided by Polymaker.