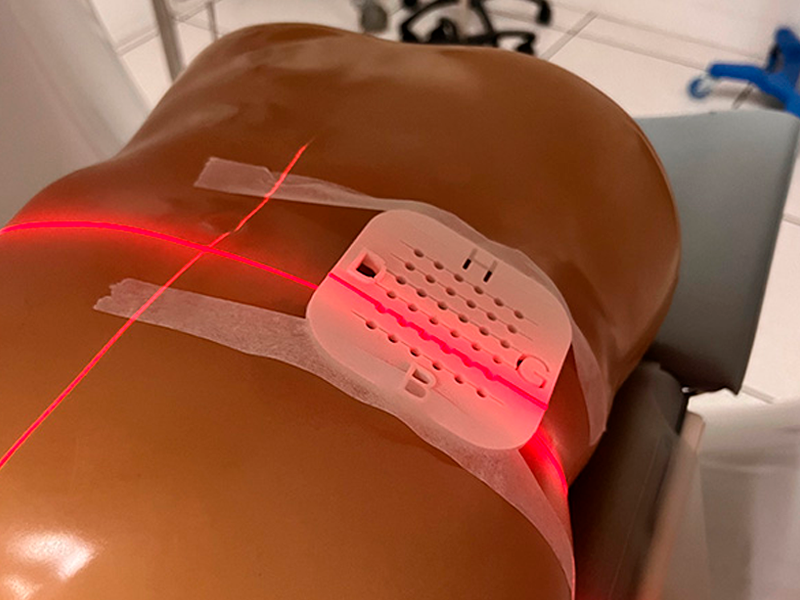

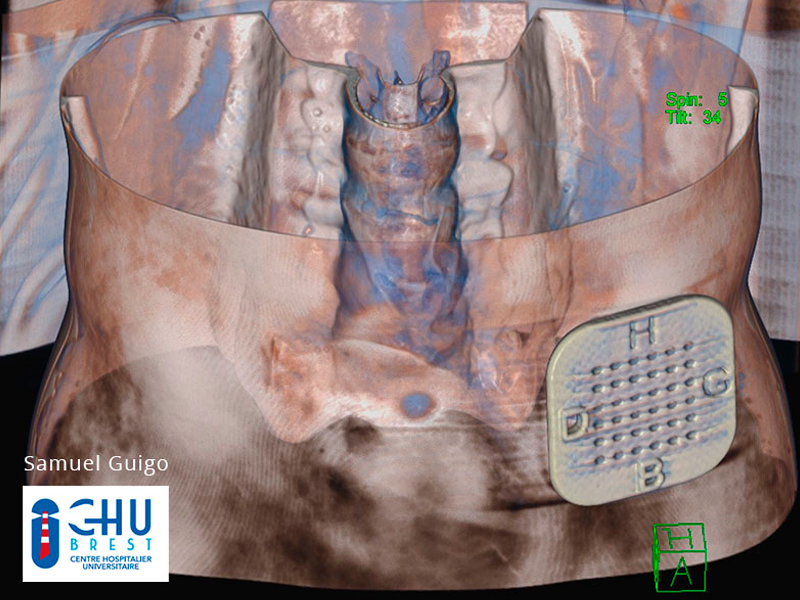

The PLA XRS pellets belong to the ample Nanovia portfolio of high quality technical pellets for 3D printing. The material is an advanced PLA that allows the 3D printing of radio-opaque parts, without using lead or any toxic materials. The x-ray shielding effect can me modified as it depends on the width of the part as well as its infill, orientation, etc.

The PLA XRS pellets print just as easy as Nanovia PLA EF, and are usable on most commercially available pellet extruders. The PLA XRS pellets (also available as PLA XRS filament) are ROHS compliant and manufactured under rigorous guidance from high quality raw material, which ensures the best mechanical and geometric properties. It should be noted that PLA XRS is not suitable for use in medical and dental implants.

Due to having PLA as the base material, the PLA XRS pellets are very easy to work with as they do not need to be extruded onto a heated bed or in a heated chamber since PLA does not have the tendency to warp. The PLA XRS pellets give the user a lot of freedom in terms of the extrusion method. They can be used to make filament with the help of a compact filament extruder such as the Felfil EVO extruder. Another option is to extrude directly onto a printing surface with the innovative Mahor V4 pellet extruder mountable on any open architecture FDM 3D printer. For larger scale projects a high speed pellet extruder such as the Dyze Pulsar pellet extruder is a great option.

General information |

|

| Manufacturer | Nanovia |

| Material | PLA |

| Format | 0.5 / 5 kg |

| Density | 1.66 g/cm³ |

Mechanical properties |

|

| Charpy impact strength | (ISO 179) 1.8 KJ/m² |

| Elongation at break | (ISO 527) 3.5 % |

| Tensile strength | - MPa |

| Tensile modulus | (ISO 527) 3500 MPa |

| Flexural strength | - MPa |

| Flexural modulus | (ISO 178) 8800 MPa |

| Surface hardness | - |

Thermal properties |

|

| Melting temperature | - ºC |

| Softening temperature | - ºC |

| Processing temperature | 210 - 240 ºC |

| Glass transition temperature | - ºC |

| Heat deflexion temperature | - ºC |

Other |

|

| HS Code | 3901.1 |

When working with the PLA XRS pellets, the user should always make sure that the workspace is properly ventilated and that face and skin protection is used. It should also be kept in mind that the pellets will preserve their longevity and give satisfying results only if they are stored properly, i.e. in a dry environment such as an airtight container with some desiccant. If the PLA XRS pellets absorb too much moisture, they should be dried for 4 hours at 50°C.

The recommended extrusion parameters for Nanovia PLA XRS pellets are 210-240°C for 3D printing. The print bed should be heated to 50-70 ºC and printing at a speed of 20-60 mm/s is recommended.

Please note that Nanovia PLA XRS material is not intended for use in medical and dental implants.