No products

Product successfully added to your cart

0 products in the cart 1 product in the cart

Pigments for Form 2/Form 3 Color Kit

The FormLabs color pigments are part of the FormLabs Color Kit - the first integrated color mixing solution for resin 3D printing. These pigments allow the users of the FormLabs 3D printers to achieve countless color variations by simply mixing a Color Base with pigments in specific amounts to create custom colors.

Image 1: A prototype made using the FormLabs pigments. Source: FormLabs.

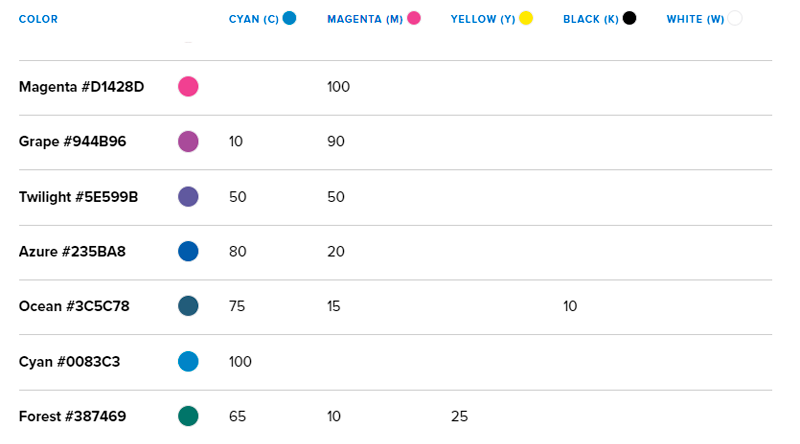

There are 5 different colors available in the pigment resin kit by FormLabs: Cyan (C), Magenta (M), Yellow (Y), Black (K) and White (W). Each pigment comes in a bottle of 115 ml and with a syringe of 10 ml. The FormLabs pigments can be used in different proportions (always reaching a total of 100 ml) to create different colors, as shown in the table below:

Image 2: Proportions required to achieve various colors with the FormLabs pigment resins. Source: FormLabs.

All 16 recipes are included in the FormLabs recipe book and on the FormLabs website. Apart from the 16 recipes prepared by FormLabs, the user can also use the custom mixer to obtain the proportions for almost infinite color variations.

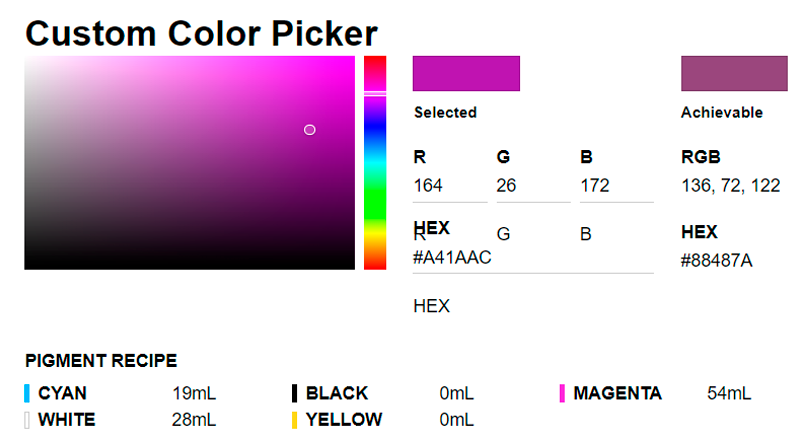

Image 3: The custom color picker for the FormLabs pigment resins. Source: FormLabs.

The desired color can be picked from in the window on the left or by introducing the RGB or HEX code on the right. It should be kept in mind that the exact desired color may not be possible to achieve, and in that case the custom color picker provides an alternative in the form of an achievable color and its RGB and HEX codes. At the very bottom, the pigment recipe is provided with the exact amount of each of the pigments required to achieve the chosen color.

The FormLabs pigments are a great coloring solution for creating looks-like prototes, concept models and props or figurines, as they allow for a quick manufacturing of already colored parts, with a wide variety of achievable colors, with no need for tedious post processing, dyeing or painting. The color resins guarantee consistent color and a smooth surface finish, as well as great mechanical properties.

| Elongation at break (%) | 12 |

| Tensile strength (MPa) | 38 |

| Tensile modulus (MPa) | 1600 |

| Flexural modulus (MPa) | 1250 |