No products

Product successfully added to your cart

0 products in the cart 1 product in the cart

Dental / Medicine

There are 51 products.Resins with specific properties such as biocompatibility, developed for specialized applications in the medical and dental sector.

-

Dental LT Clear Resin - FormLabs Dental LT Clear Resin - FormLabs

349,00 € tax excl.

349,00 € tax incl.Ideal material for direct printing splints, retainers and other orthodontic devices. Ideal material for direct printing splints, retainers and other orthodontic devices.

-

Dental Resin - HARZ Labs Dental Resin - HARZ Labs

120,00 € tax excl.

120,00 € tax incl.Range of materials that covers all the needs of the dental sector, valid for all types of 3D printers. Range of materials that covers all the needs of the dental sector, valid for all types of 3D printers.

-

KeyModel Ultra resin KeyModel Ultra resin

83,00 € tax excl.

83,00 € tax incl.Dental resin for the 3D printing of dental models, ideal for thermoforming. Dental resin for the 3D printing of dental models, ideal for thermoforming.

-

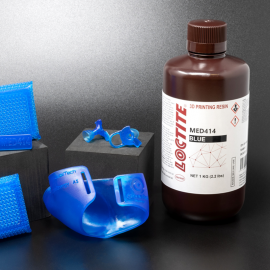

MED414 resin - Loctite 3D MED414 resin - Loctite 3D

450,00 € tax excl.

450,00 € tax incl.Soft resin with great elongation and tear strength, ideal for elastomeric medical applications. Soft resin with great elongation and tear strength, ideal for elastomeric medical applications.

-

Surgical Guide Dental Resin - FormLabs Surgical Guide Dental Resin - FormLabs

249,00 € tax excl.

249,00 € tax incl.Biocompatible material designed for 3D printing of surgical aid devices. Biocompatible material designed for 3D printing of surgical aid devices.

-

BASF Ultracur3D DM 2505 Model BASF Ultracur3D DM 2505 Model

94,05 € tax excl.

94,05 € tax incl. 99,00 € -5%Dental resin developed for the manufacture of non-medical gingival masks. Dental resin developed for the manufacture of non-medical gingival masks.

Reduced price! -

Liqcreate Gingiva Mask resin Liqcreate Gingiva Mask resin

46,95 € tax excl.

46,95 € tax incl.Dental resin for the manufacturing of gum-like parts for dental implant models. Dental resin for the manufacturing of gum-like parts for dental implant models.

-

KeyTray resin KeyTray resin

244,40 € tax excl.

244,40 € tax incl.Biocompatible resin for creating strong and durable customized impression trays. Biocompatible resin for creating strong and durable customized impression trays.

-

MED413 Resin - Loctite 3D MED413 Resin - Loctite 3D

430,00 € tax excl.

430,00 € tax incl.High performance resin ideal for impact resistant applications in medicine. High performance resin ideal for impact resistant applications in medicine.

-

Dental Model Resin - FormLabs Dental Model Resin - FormLabs

135,00 € tax excl.

135,00 € tax incl.High performance material for SLA impression of dental crown and bridge models. High performance material for SLA impression of dental crown and bridge models.

-

KeyOrtho IBT resin KeyOrtho IBT resin

385,90 € tax excl.

385,90 € tax incl.Biocompatible, tasteless and odorless dental resin for indirect bonding trays. Biocompatible, tasteless and odorless dental resin for indirect bonding trays.

-

Custom Tray dental resin - FormLabs Custom Tray dental resin - FormLabs

249,00 € tax excl.

249,00 € tax incl.Resin oriented to the direct manufacture of robust and precise dental impression trays. Resin oriented to the direct manufacture of robust and precise dental impression trays.

-

KeySplint Soft resin KeySplint Soft resin

265,00 € tax excl.

265,00 € tax incl.Biocompatible resin designed for the 3D printing of flexible orthodontic devices with elastic memory. Biocompatible resin designed for the 3D printing of flexible orthodontic devices with elastic memory.

-

Biomed Amber Resin - FormLabs Biomed Amber Resin - FormLabs

249,00 € tax excl.

249,00 € tax incl.Rigid and biocompatible material for applications requiring short-term contact. Rigid and biocompatible material for applications requiring short-term contact.

-

Liqcreate Model Pro Beige resin Liqcreate Model Pro Beige resin

46,95 € tax excl.

46,95 € tax incl.Dental resin for the manufacturing of highly accurate dental models, dies and aligner models. Dental resin for the manufacturing of highly accurate dental models, dies and aligner models.

-

Biomed Clear Resin - FormLabs Biomed Clear Resin - FormLabs

349,00 € tax excl.

349,00 € tax incl.Biocompatible material suitable for the manufacture of durable parts that require low water absorption. Biocompatible material suitable for the manufacture of durable parts that require low water absorption.

-

BASF Ultracur3D DM 2304 Gingiva Mask BASF Ultracur3D DM 2304 Gingiva Mask

171,95 € tax excl.

171,95 € tax incl. 181,00 € -5%Dental resin developed for the manufacture of non-medical gingival masks. Dental resin developed for the manufacture of non-medical gingival masks.

Reduced price! -

Temporary CB dental resin - FormLabs Temporary CB dental resin - FormLabs

499,00 € tax excl.

499,00 € tax incl.Dental resin for making temporary crown and bridge restorations. Dental resin for making temporary crown and bridge restorations.

-

Liqcreate Wax Castable resin Liqcreate Wax Castable resin

90,90 € tax excl.

90,90 € tax incl.Castable wax resin for jewelry and dental uses with clean and ash-free burn-out. Castable wax resin for jewelry and dental uses with clean and ash-free burn-out.

-

KeyMask resin KeyMask resin

187,20 € tax excl.

187,20 € tax incl.Dental resin for the 3D printing of gingival masks with realistic gum tissue look and feel. Dental resin for the 3D printing of gingival masks with realistic gum tissue look and feel.

-

IBT Resin - Formlabs IBT Resin - Formlabs

249,00 € tax excl.

249,00 € tax incl.Flexible biocompatible material for efficient and precise placement of dental brackets. Flexible biocompatible material for efficient and precise placement of dental brackets.

-

Liqcreate Model Pro Grey resin Liqcreate Model Pro Grey resin

46,95 € tax excl.

46,95 € tax incl.High accuracy dental resin for the 3D printing of dental models and aligner models. High accuracy dental resin for the 3D printing of dental models and aligner models.

-

Permanent Crown Resin - Formlabs Permanent Crown Resin - Formlabs

790,00 € tax excl.

790,00 € tax incl.Biocompatible dental resin for making permanent restorations. Biocompatible dental resin for making permanent restorations.

-

KeyCast resin KeyCast resin

124,27 € tax excl.

124,27 € tax incl.High speed dental resin for residue-free precise castings with low shrinkage. High speed dental resin for residue-free precise castings with low shrinkage.

-

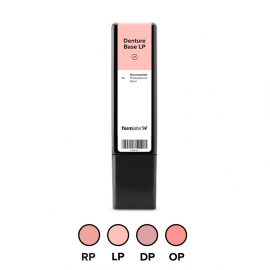

Dental Denture base resin - Formlabs Dental Denture base resin - Formlabs

299,00 € tax excl.

299,00 € tax incl.Material developed for the fabrication of high quality complete dentures. Material developed for the fabrication of high quality complete dentures.

-

Ultracur3D® DMD 1005 Ultracur3D® DMD 1005

384,75 € tax excl.

384,75 € tax incl. 405,00 € -5%Daylight technology resin ideal for the manufacture of dental models and moulds. Daylight technology resin ideal for the manufacture of dental models and moulds.

Reduced price! -

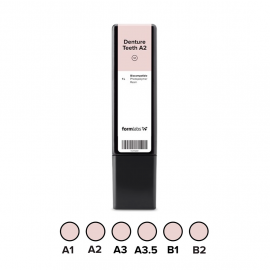

Dental Denture teeth resin - Formlabs Dental Denture teeth resin - Formlabs

399,00 € tax excl.

399,00 € tax incl.Material developed for the fabrication of high quality complete dentures. Material developed for the fabrication of high quality complete dentures.

-

KeyGuide resin KeyGuide resin

260,00 € tax excl.

260,00 € tax incl.Biocompatible sterilizable resin for making transparent and stable surgical guides. Biocompatible sterilizable resin for making transparent and stable surgical guides.

-

Castable Wax Resin - FormLabs Castable Wax Resin - FormLabs

299,00 € tax excl.

299,00 € tax incl.Enhance the work of jewelry and dental sector more quickly and economically than with traditional methods. Enhance the work of jewelry and dental sector more quickly and economically than with traditional methods.

-

KeySplint Hard resin KeySplint Hard resin

265,20 € tax excl.

265,20 € tax incl.Biocompatible resin designed for the 3D printing of rigid dental splints. Biocompatible resin designed for the 3D printing of rigid dental splints.

-

Soft Tissue Resin Kit - Formlabs Soft Tissue Resin Kit - Formlabs

256,00 € tax excl.

256,00 € tax incl.Resin for printing in 3D soft tissue examples for dental implant modelling. Resin for printing in 3D soft tissue examples for dental implant modelling.

-

Liqcreate Premium Model resin Liqcreate Premium Model resin

29,74 € tax excl.

29,74 € tax incl.Dental resin for the fast, accurate and odorless printing of dental models and aligners. Dental resin for the fast, accurate and odorless printing of dental models and aligners.

-

Biomed Resin - FormLabs Biomed Resin - FormLabs

349,00 € tax excl.

349,00 € tax incl.Biocompatible resins for short and long-term applications for tools and end uses. Biocompatible resins for short and long-term applications for tools and end uses.

-

KeyDenture Try-In Resin KeyDenture Try-In Resin

156,27 € tax excl.

156,27 € tax incl.Biocompatible resin designed for the 3D printing of try-in dentures, available in 3 colors. Biocompatible resin designed for the 3D printing of try-in dentures, available in 3 colors.

-

Dental LT Clear V2 Resin - FormLabs Dental LT Clear V2 Resin - FormLabs

439,00 € tax excl.

439,00 € tax incl.Resistant and color-corrected biocompatible resin for Form 2 and Form 3B. Resistant and color-corrected biocompatible resin for Form 2 and Form 3B.

-

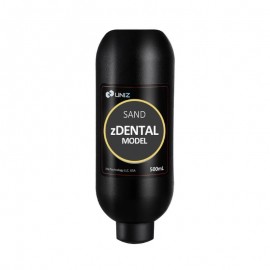

Zortrax Druckwege Dental Model Zortrax Druckwege Dental Model

65,00 € tax excl.

65,00 € tax incl.Resin compatible with LED-LCD printers for the production of dental models. Resin compatible with LED-LCD printers for the production of dental models.

-

Dentistry Resin (UniZ) Dentistry Resin (UniZ)

73,00 € tax excl.

73,00 € tax incl.Aimed at dental applications such as final dental models, orthodontic molds or plastic prostheses. Aimed at dental applications such as final dental models, orthodontic molds or plastic prostheses.

-

Zortrax Raydent Dental Resins Zortrax Raydent Dental Resins

365,00 € tax excl.

365,00 € tax incl.Biocompatible dental resins compatible with 405 nm LED-LCD printers. Biocompatible dental resins compatible with 405 nm LED-LCD printers.

-

zWAX (UniZ) zWAX (UniZ)

169,00 € tax excl.

169,00 € tax incl.Designed to be used directly in the casting process, reduce manufacturing time drastically. Designed to be used directly in the casting process, reduce manufacturing time drastically.

-

Dental Study Model resin Phrozen Dental Study Model resin Phrozen

61,95 € tax excl.

61,95 € tax incl.Affordable and fast resin for applications in dentistry and orthodontics. Affordable and fast resin for applications in dentistry and orthodontics.

-

Water-Washable resin Phrozen Water-Washable resin Phrozen

41,25 € tax excl.

41,25 € tax incl.Water washable resins ideal for beginners. Perfect for the 3D printing of miniatures. Water washable resins ideal for beginners. Perfect for the 3D printing of miniatures.

-

xDENT201 resin Nexa 3D xDENT201 resin Nexa 3D

105,00 € tax excl.

105,00 € tax incl.High-resolution resin for the 3D printing of accurate dental models with great dimensional stability. High-resolution resin for the 3D printing of accurate dental models with great dimensional stability.

-

xDENT341 resin Nexa 3D xDENT341 resin Nexa 3D

149,00 € tax excl.

149,00 € tax incl.Resin for removable die models with incredible accuracy and dimensional stability. Resin for removable die models with incredible accuracy and dimensional stability.

-

Liqcreate Bio-Med Clear resin Liqcreate Bio-Med Clear resin

90,90 € tax excl.

90,90 € tax incl.Rigid clear resin for highly accurate sterilizable biocompatible parts. Rigid clear resin for highly accurate sterilizable biocompatible parts.

-

Biomed Flex Resin - FormLabs Biomed Flex Resin - FormLabs

239,00 € tax excl.

239,00 € tax incl.Certified biocompatible material for medical-grade parts with durability and transparency. Certified biocompatible material for medical-grade parts with durability and transparency.

-

Biomed Elastic Resin - FormLabs Biomed Elastic Resin - FormLabs

339,00 € tax excl.

339,00 € tax incl.Biocompatible resin for the manufacture of soft, comfortable and transparent medical-grade parts. Biocompatible resin for the manufacture of soft, comfortable and transparent medical-grade parts.

-

MED9851 resin - Loctite 3D MED9851 resin - Loctite 3D

430,00 € tax excl.

430,00 € tax incl.Resin for stiff and tough medical device applications with great tensile and flexural properties. Resin for stiff and tough medical device applications with great tensile and flexural properties.

-

Gingiva Mask resin Phrozen Gingiva Mask resin Phrozen

107,40 € tax excl.

107,40 € tax incl.Resin for dental applications. High elasticity and dimensional and color stability. Resin for dental applications. High elasticity and dimensional and color stability.

-

Castable W20 Green resin Phrozen Castable W20 Green resin Phrozen

118,80 € tax excl.

118,80 € tax incl.Castable resin for fine and delicate designs in dental and jewelry applications. Castable resin for fine and delicate designs in dental and jewelry applications.

-

Castable W40 Orange resin Phrozen Castable W40 Orange resin Phrozen

131,28 € tax excl.

131,28 € tax incl.Castable resin for large pieces in dental and jewelry applications. Castable resin for large pieces in dental and jewelry applications.

-

Castable Dental Green resin Phrozen Castable Dental Green resin Phrozen

115,62 € tax excl.

115,62 € tax incl.Castable resin designed specifically for casting in the dental sector. Castable resin designed specifically for casting in the dental sector.

Dental Resins

The dental sector always requires products with high precision and a high surface finish. Previously, generic elements and tools were used for all patients, taking up a lot of time in easy operations. For this reason, large manufacturers of SLA technology 3D printers such as FormLabs or HarzLabs have developed specific products for this sector: Dental resins.

Dental resins are specialised materials for the dental field, where the use of this type of technology is increasingly present. Thanks to these resins it is possible to make models of crowns and bridges, surgical guides, splints and retainers with incredible accuracy and with very low material costs for each element, much lower than those caused by traditional methods. This, together with the speed and possibility of manufacturing a personalised model adapted to each patient, makes dental resins an innovative product in the dental sector.

Medical Resins

Medical resins are advanced medical grade materials specifically developed for use in a wide variety of health care applications, such as those requiring contact with the patient's skin and/or mucous membrane.

With the use of these resins, strong and functional parts can be produced that are also biocompatible. Moreover, parts made of these materials are compatible with the most common sterilisation techniques.