No products

Product successfully added to your cart

0 products in the cart 1 product in the cart

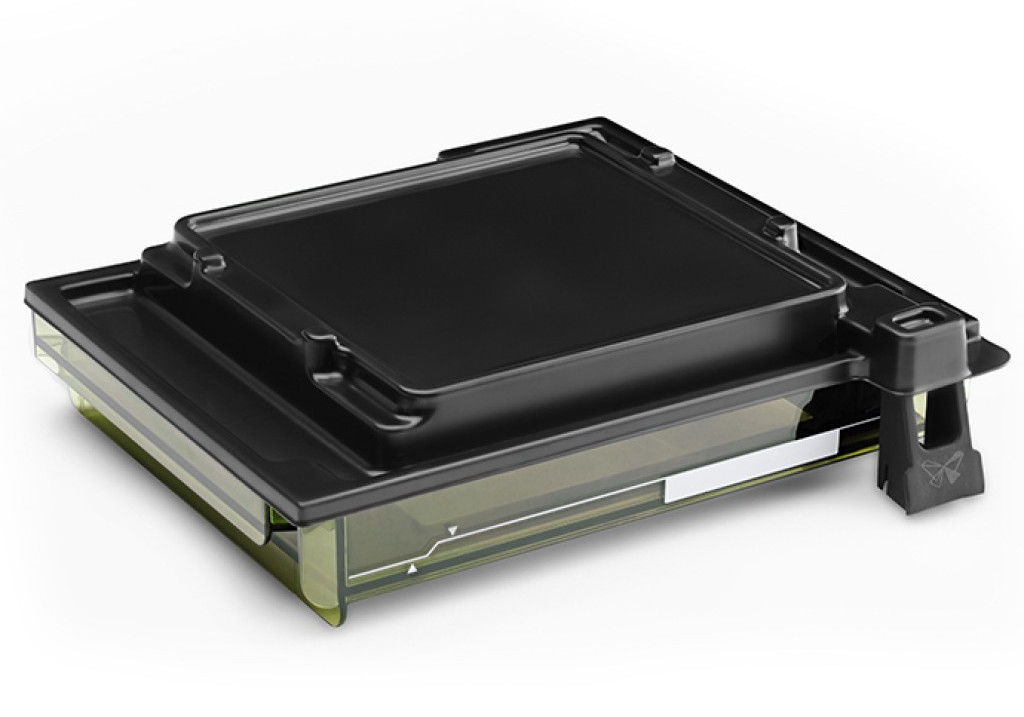

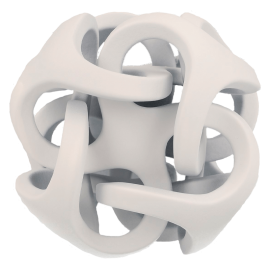

FormLabs Engineering Resins are a set of resins developed to solve the most complex engineering challenges thanks to the wide variety of functional materials. In addition, these materials help to reduce costs and make quality prototypes and final parts very quickly. Within this family of resins are the Rigid resins.

.jpg)

Image 1: Engineering Resins FormLabs. Source: FormLabs

Formlabs' Rigid resins are strong and stable resins, ideal for creating strong and rigid prototypes of parts that are resistant to bending. This family includes:

- Rigid Resin 4000 (formerly called Rigid Resin)

- Rigid Resin 10K

Parts made from these materials are thermally and chemically resistant and their dimensions remain stable under load.

These resins are ideal for: Turbines and fan blades, guides, fasteners and tooling, fluid and air flow components, covers for electrical appliances or covers for appliances in cars among others.

When comparing the two resins in the Rigid family, Rigid 4000 resin is more suitable for rigid and resistant engineering parts capable of withstanding minimal deflection, while the high glass content of Rigid 10K resin makes it ideal for the manufacture of extremely rigid and resistant industrial parts that require complete rigidity and high stability.

Rigid Resin 4000

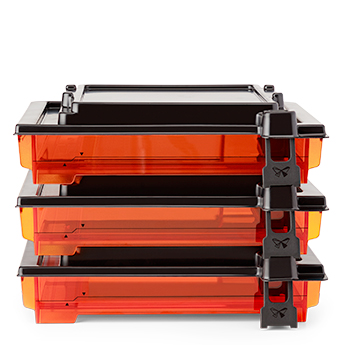

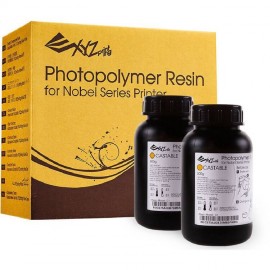

The Rigid Resin 4000 is a resin highly reinforced with glass, giving it a high rigidity and a completely smooth or polished finish. It's also resistant to temporary deformation and allows to print thin-walled parts, but at the same time resistant.

Rigid 4000 resin is comparable to other fiberglass reinforced thermoplastics. Compared to parts printed with other Formlabs materials, parts printed with Rigid 4000 resin resist mechanical stress for a longer period of time.

Image 2: Part of thin and resistant walls. Source: FormLabs.

Rigid 10K

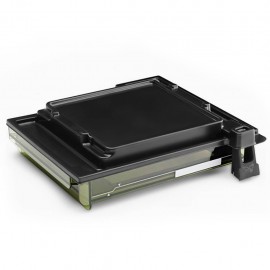

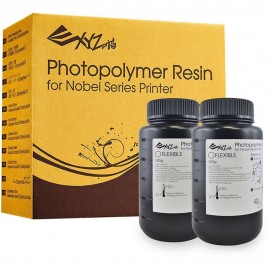

As for Rigid 10K resin, it is the most rigid material in Formlabs' range of engineering resins, making it ideal for industrial parts that need to support a significant load without bending. Rigid 10K resin has a smooth matt finish and is highly resistant to heat and chemicals.

Because of its properties, 10K Rigid resin can be used for high performance applications in a variety of industries such as automotive and aerospace.

One of the newest applications of 10K Rigid resin is injection moulding. By incorporating 3D printing into the injection molding process, manufacturers can eliminate time-consuming and costly metal machining. The toughness, rigidity and heat resistance of 10K Rigid resin make it an ideal material for short series injection moulding.

Due to the properties of the material, a mould made from this material can withstand the pressures of injection without breaking. Its stiffness ensures that the mould maintains its shape even under pressure, resulting in precise parts. Its high thermal resistance makes it possible for the mould to maintain its rigidity even at the high temperatures to which the material is exposed during the injection process.

Image 3: Parts printed with 10K Rigid resin. Source: Formlabs.

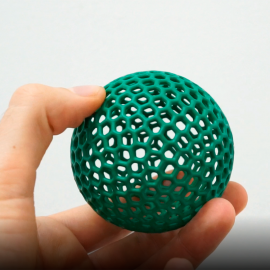

Rigid resins support printing resolutions of 100 and 50 microns, which results in a very high surface finish and level of detail on the pieces.

Thus, the resins of the Rigid family are very useful materials in a wide variety of sectors and applications thanks to their mechanical properties.

Thanks to Rigid Resin family and other FormLabs engineering resins, costs can be reduced and quality prototypes and final parts can be made very quickly.

| Impact strength (KJ/m2) | 2 |

| Elongation at break (%) | 9 |

| Tensile strength (MPa) | 57 |

| Tensile modulus (MPa) | 3150 |

| Flexural strength (MPa) | 85 |

| Flexural modulus (MPa) | 2535 |

| Softening temperature (ºC) | 88 |

| Hide color variations | (Hide color variations) |