No products

Product successfully added to your cart

0 products in the cart 1 product in the cart

View larger

View larger

Custom Tray dental resin - FormLabs

RS-FORM-CUSTOMTRAY

This product could be delivered in a period exceeding the standard.

New product

FormLabs Dental Resins are specialized materials for the dental field, where the use of this type of technology is increasingly present. The dental resins allow the production of models of crowns and bridges, surgical guides, splints and retainers with incredible accuracy, with a maximum deviation of ±100 microns, and with very low material costs per element (1.4 - 3.3 €), which amortizes the use of the printer with any of the dental resins in a few months.

Formlabs' wide range of dental resins allows dental practices and laboratories to quickly manufacture a variety of dental products in their own facilities, from biocompatible surgical guides and splints to models for fixed prostheses and clear aligners.

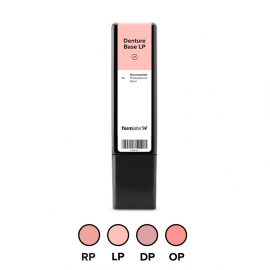

Formlabs has developed the Custom Tray resin, a biocompatible material for directly printing dental impression trays for implants, prostheses, crowns and bridges, as well as other more complex applications. Digitally manufactured dental impression trays provide robust and accurate impressions for high quality dental service.

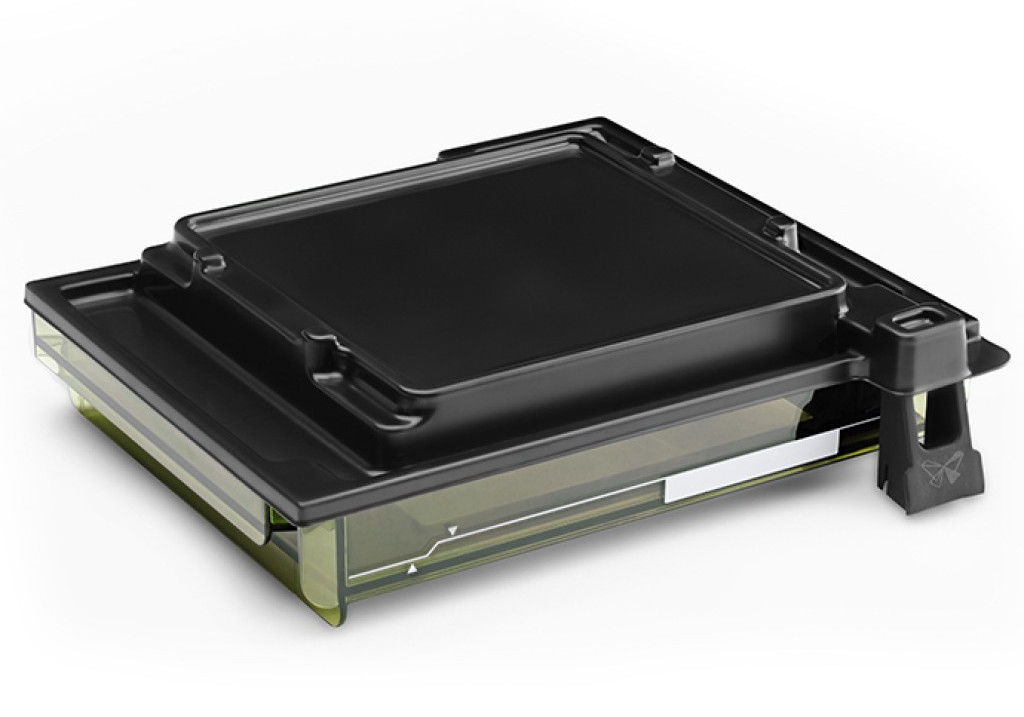

Image 1: Print tray printed with Custom Tray Font: Formlabs.

Custom Tray is a fast printing material that allows the use of layer heights up to 200 microns, thus reducing working time and achieving higher performance.

This resin is not compatible with Form 3. To use the Custom Tray resin and carry out the printing process optimally, the following materials and devices must be used:

- Form 2 or Form 3B 3D printer.

- Requires LT resin tank in case of Form 2 printer and V2 resin tank in case of Form 3B printer.

- Construction platform.

- Resina Custom Tray.

- Form Wash.

- Form Cure.

- Finishing kit.

The manufacturing process with the Custom Tray resin is the following:

1. Scanning: To begin, the patient's anatomy must be scanned. In this way, a digital impression of the patient's anatomy will be obtained, on which to work and create a custom tray.

2. Design: Different dental software is available to digitally design custom impression trays. One of them is ZirkonZahn.Tray; a free dental CAD software for designing custom trays that integrates with FormLabs Preform Software.

3. 3D printing: To print the digitally designed file, you must import it from Preform, select the material to be used, and modify the different options offered by the Software regarding orientation, supports, etc.

4. Post-processing: First, the parts must be removed from the construction platform. Then, the parts must be washed, dried and cured according to the parameters indicated in the "Specifications" section. Finally, the supports must be carefully removed and any areas where the supports have left any uneven areas must be polished with a hand motor.

5. Cleaning and disinfection: Finally, the parts must be cleaned and disinfected. After cleaning, look for cracks in the workpiece. If any cracks are found, the workpiece must be discarded immediately. A proven method for disinfection is to immerse the parts in a solution with 70% IPA alcohol for 5 minutes. After disinfection, the part should be re-inspected for cracks.

To download the complete printing guide, go to "Downloads".

Thus, the Custom Tray resin is a biocompatible material, designed to be used in a wide variety of applications in the dental industry.

To ensure the biocompatibility of Custom Try resin, the use of dedicated tanks, construction platform and finishing kits are required and should only be used with this and other biocompatible Formlabs resins.

| Elongation at break (%) | 3.2 |

| Tensile strength (MPa) | 74 |

| Tensile modulus (MPa) | 2900 |

| Flexural strength (MPa) | 110 |

| Flexural modulus (MPa) | 2700 |

| Surface hardness | 8 |

| Medical use | Medical use |

| Hide color variations | (Hide color variations) |