No products

Product successfully added to your cart

0 products in the cart 1 product in the cart

View larger

View larger

Temporary CB dental resin - FormLabs

FormLabs Dental Resins are specialized materials for the dental field, where the use of this type of technology is increasingly present. The dental resins (biocompatible) allow models of crowns and bridges, surgical guides, splints and retainers to be made with incredible accuracy, with a maximum deviation of ±100 microns, and with very low material costs per element (1.4 - 3.3 €), which amortizes the use of the printer with any of the dental resins in a few months.

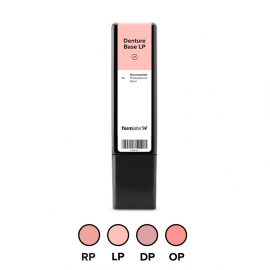

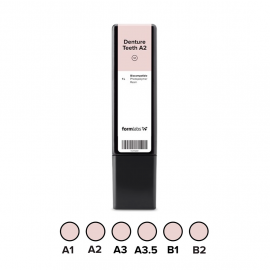

Temporary CB is a tooth-coloured resin, developed for the purpose of 3D printing of temporary crown and bridge restorations, inlays and onlays and veneers. It can be used for bridges of up to seven units and is available in the following VITA shades:

- A2

- A3

- B1

- C2

- BL

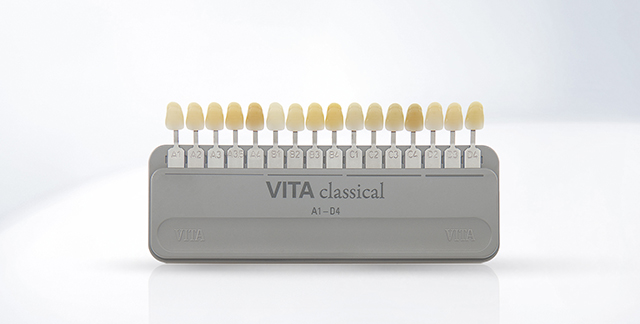

Image 1: VITA colour chart. Source: vita-zahnfabrik.

In addition, it provides excellent edge adaptation, strength and aesthetics.

Traditional temporary cements should be used to secure restorations made of Temporary CB resin. Restorations made with the Temporary CB resin can remain in the mouth for up to 12 months. Digitally created restorations enable a fast and collaborative process between dentists, technicians and patients.

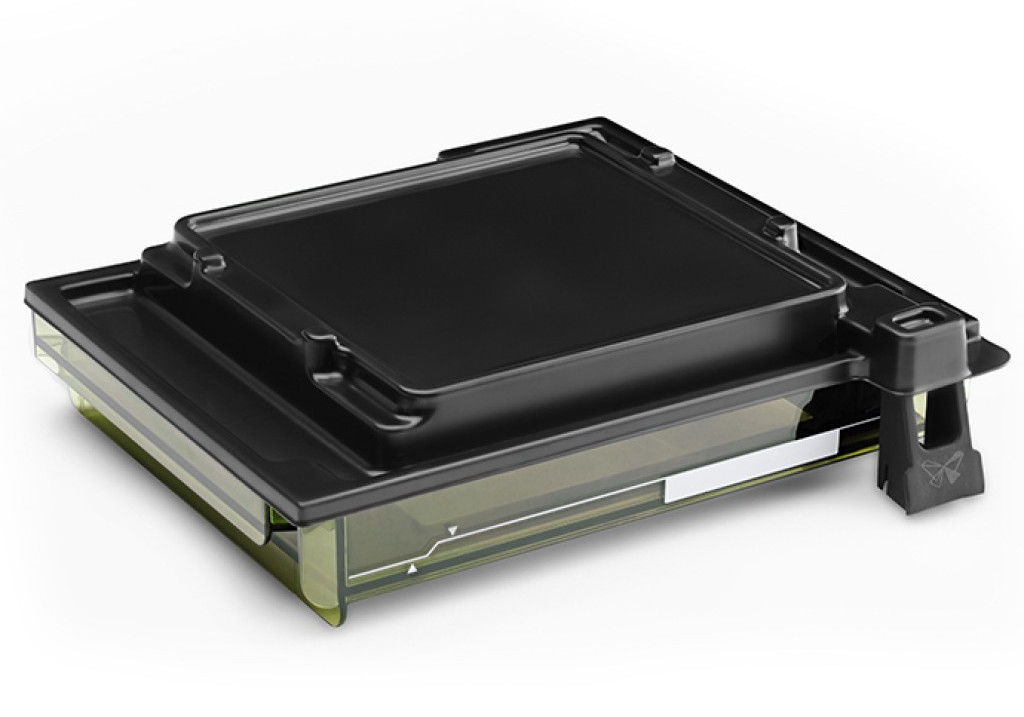

To print with the CB Temporary Resin, a Stainless Steel Fabrication Platform is required. The Temporary CB Resin contains a ceramic filler that would produce abrasion on the standard impression platform, causing contamination of the resin and possible staining or colour modification. By using the Stainless Steel Fabrication Platform we avoid abrasion and its negative effects.

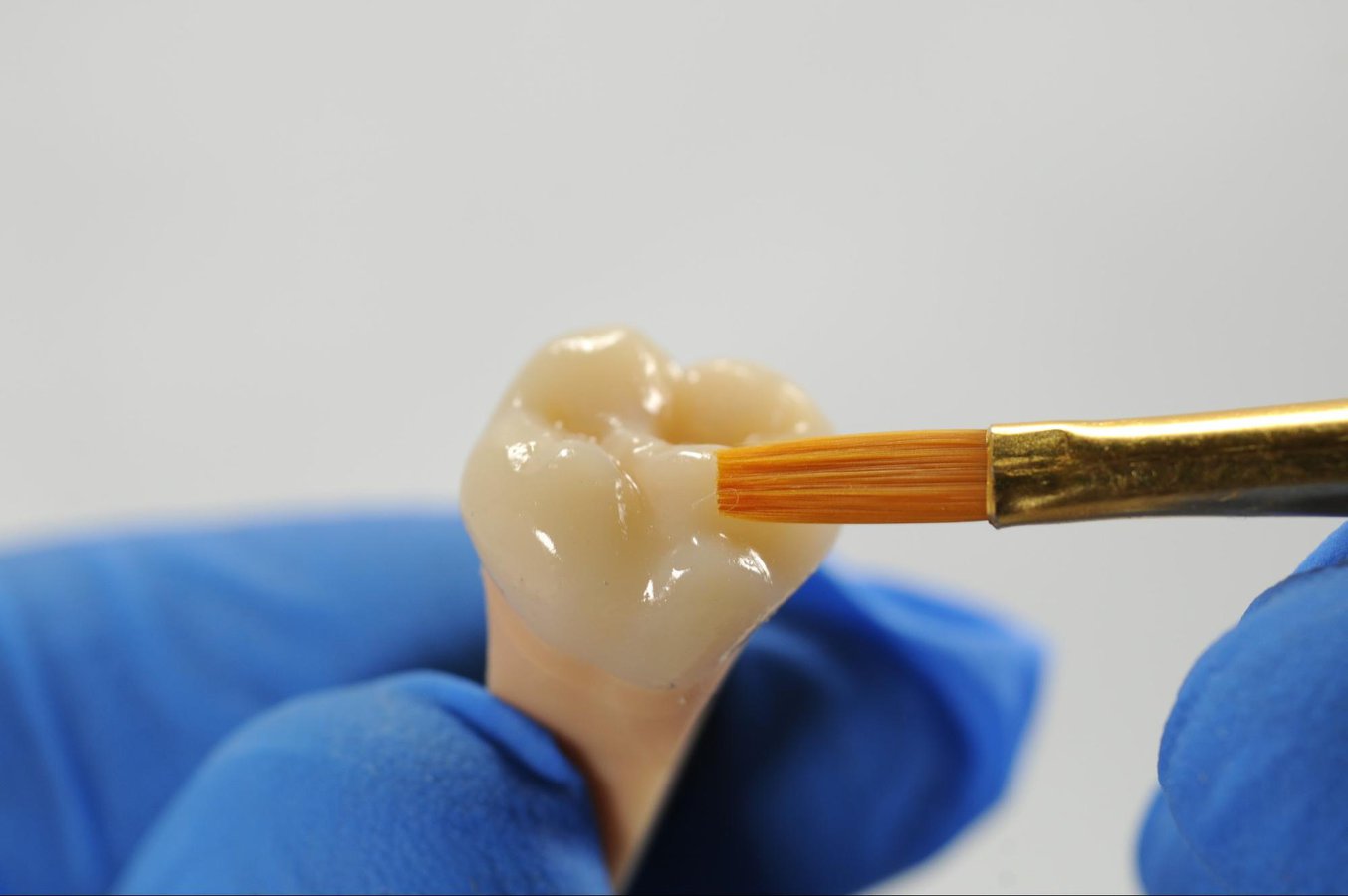

In addition, parts printed with Temporary CB can be tinted using light-curable coatings such as GC Optiglaze.

Image 2: Piece printed with Temporary CB and nuanced. Source: FormLabs.

The combined use of the Stainless Steel Fabrication Platform and the Temporary CB resin ensures a uniform shade and maintenance of the material properties. This platform is not necessary when using other FormLabs resins.

Applications in the dental sector:

- Development of bridges.

- Onlay, Inlay restorations

- Temporary veneers.

Temporary CB resin is a biocompatible material that can be implanted for a period of less than one year, designed for use in a wide variety of applications in the dental industry.

This resin is not compatible with Form 3. It requires the use of a LT resin tank in case of using a Form 2 and the use of a Stainless Steel Fabrication Platform.

To ensure the biocompatibility of Temporary CB resin, the use of dedicated tanks, stainless steel construction platform and finishing kits are required and should only be used with this and other biocompatible Formlabs resins.

| Medical use | Medical use |

| Hide color variations | (Hide color variations) |