No products

Product successfully added to your cart

0 products in the cart 1 product in the cart

PolyTerra PLA is an environmentally friendly 3D printing filament developed by the renowned FDM 3D printing materials manufacturer Polymaker. Polymaker has a wide range of filaments, including conventional materials as well as technical materials for professional users.

PolyTerra PLA is a bioplastic developed from scratch by combining PLA with organic minerals, thus significantly reducing the plastic content of the filament, producing a more environmentally friendly FDM 3D printing material.

Image 1: PLA Polyterra standard colours. Source: Polymaker.

In addition, to offset the carbon emissions generated in the manufacture and transport of each spool, Polymaker, in collaboration with OneTreePlanted.org, plants a tree for each spool sold. This way, when the tree reaches maturity, it will be able to absorb 22 Kg of carbon dioxide per year, offsetting the 4 Kg needed to manufacture one PolyTerra PLA spool.

Image 2: PolyTerra filament spool. Source: Polymaker.

PLA is a biodegradable polymer obtained from natural resources such as starch extracted from corn, sugar beet or wheat. This material is one of the most widely used in 3D printing because it does not give off harmful gases and is easy to print. Thanks to its PLA content, PolyTerra PLA filament can be printed in the same configuration as PLA, does not require a heated bed and warping is almost non-existent. The low technical requirements of this material make it possible to use it in almost any FDM 3D printer on the market.

Image 3: The army colors of Polyterra PLA. Source: Polymaker.

In addition to the qualities it shares with standard PLAs, PolyTerra PLA allows the 3D printing of parts with overhangs and bridges with a quality far superior to other PLAs. Furthermore, the surface finish of 3D printed parts is excellent and completely matt. This finish allows layer lines to be hidden, even when printing with large layer heights.

Image 4: Matt surface of parts printed with PolyTerra. Source: Polymaker.

PolyTerra's mechanical properties are superior to those of standard PLA, allowing for a wide range of possible applications in different sectors. PolyTerra PLA is stronger than standard PLA, and has a similar stiffness to PolyMax PLA.

Image 5: The muted colours of PolyTerra PLA. Source: Polymaker.

The qualities of this material do not end there, as PolyTerra PLA allows for easy post-processing. Supports printed with PolyTerra PLA can be easily removed without the use of tools. This allows the user to manufacture complex parts, achieving excellent finishes.

Video 1: Simple removal of brackets without tools. Source: Polymaker.

In addition, the surface of the printed parts can be sanded without any problem, without fear of creating unwanted residues on the surface. And, thanks to its porous surface, 3D printed parts made of this material can be painted, and a wide range of paints can be used. All these properties make PolyTerra PLA an ideal material for the manufacture of figures or accessories.

Image 6: Pieces printed with PolyTerra PLA pastel colours. Source: Polymaker.

PolyTerra PLA is available in a wide range of colours, among which several pastel colours have been introduced, all of them with an excellent surface finish.

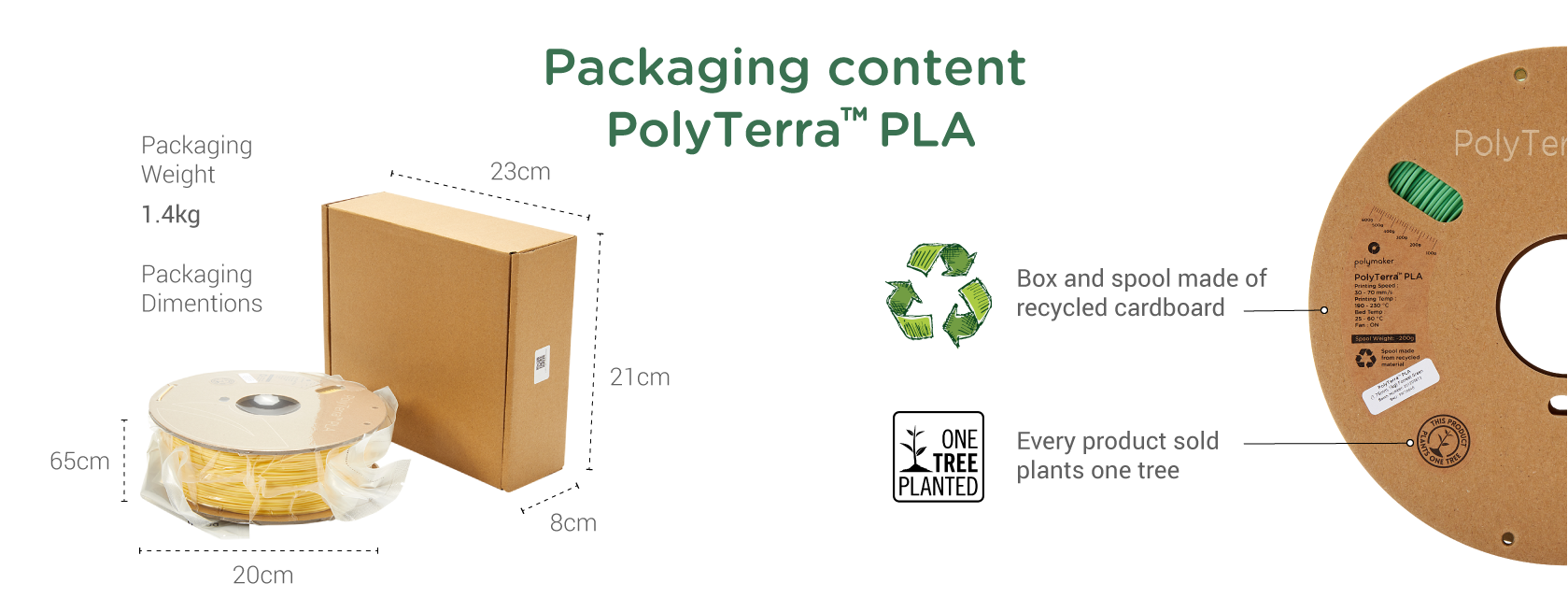

Image 7: Packaging of PolyTerra filaments. Source: Polymaker.

Polymaker has also taken into account the packaging of the filaments to reduce the environmental impact of the product. PolyTerra PLA filament is wound on a recycled cardboard spool, with labels and outer packaging also made of recycled material. In addition, all unnecessary paper has been removed from the packaging to reduce the waste produced in the manufacture of the material.

Polymaker spool adapter

In the download section you will find the STL and STEP files to 3D print your own Polymaker spool adapter. This durable spool adapter helps reduce friction by creating a structured running surface, and also avoids the dust build-up associated with similar adapter solutions. The spool adapter was created with the Polymaker cardboard spools in mind to compensate for any spool deformation that could influence spool stability.

Video 2: The Polymaker spool adapter. Source: Polymaker.

This Polymaker spool adapter is compatible with all multi-material stations, such as Bambu Lab's AMS or Ultimaker's Material Station. Printing the adapter requires about 40 minutes and 30 g of filament. Recommended materials are PLA, PolyLite PETG, PolyLite ASA or PolyMax PLA for durability and longevity. To extend the life of the spool adapter, Polymaker suggests first removing the locating pin before removing the edge clips to reduce stress on the adapter when changing spools.

| Impact strength (KJ/m2) | 6 |

| Elongation at break (%) | 35 |

| Tensile strength (MPa) | 21 |

| Tensile modulus (MPa) | 1882 |

| Softening temperature (ºC) | 63 |

| Biodegradable | Biodegradable |