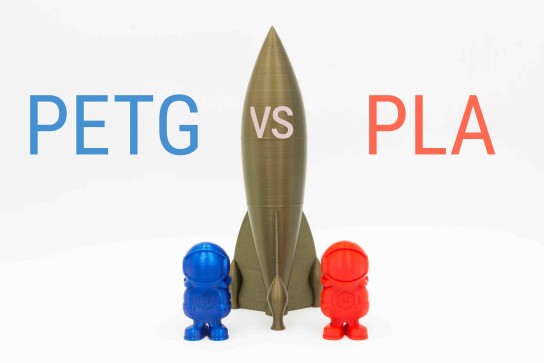

Following the theme of the previous article, below we cite the differences and similarities between the PETG and the PLA.

The PLA and the PETG are two of the most common materials in the world of 3D printing thanks to its ease of printing, good results and wide range of colors.

PLA (lactic polyacid) is an ideal polymer for 3D printing due to its low handling temperatures, 180-210 °C extruder and 0-50 °C base, low thermal shrinkage and the absence of odor during printing. All this together with the fact that it is biodegradable and at a very low price, it is not surprising that the PLA is the material most consumed in the world of 3D printing FDM / FFF.

The PLA and the PETG show many similar properties, where by normal the PETG takes the victory. At the mechanical level, the PETG has a better behavior, with an elastic modulus far superior to the PLA, but as a disadvantage the PETG is grated with greater ease. In the thermal resistance, the copolyester achieves a value of 80 °C, lower than ABS (100 ºC) but higher than the vast majority of PLA (60 ºC). At the time of post-processing, the PLA is simpler, if we want to paint a piece, we should only choose an acrylic paint, if we want to paste them, we should choose a cyanoacrylate glue (PrintGlue), instead, post-processing the PETG is still a complex process. When parts are made for the exterior, the PETG is more resistant to the action of the sun, rain and cold, although there are solutions such as the Plastimperm F10 to waterproof parts manufactured with PLA. When printing complex parts, with supports, it is usually easier with PLA, due to the greater difficulty of removing the PETG supports due to its great adhesion between layers. One solution is to use a soluble support material, such as the Mowiflex 3D 2000. Most PETG colors have a high percentage of translucency, which is positive in many cases but which makes it difficult to always obtain the same color code, instead, with the PLA can be obtained without problem the same color code RAL and Pantone.

Image 1: Great translucence of the CPE GH100. Source: Fillamentum

In relation to the printing properties of these two materials, every user of a 3D printer knows that the PLA is the simplest material to use. Both the PLA and the PETG can be printed with a cold base with the help of some type of adhesive (3DLac, DimaFix, PrintaFix, Magigoo...) but it is advisable to use a hot base especially for large pieces with PETG (60-80 ºC). f you have a PEI base, you must be very careful and apply PVA or Magigoo glue to reduce the adherence of the PETG, If you do not do this, there will probably be a rupture of the PEI sheet at the time of remove the printed piece. Due to the higher density of the PETG (1.27 g/cm³) compared to the PLA (1.24 g/cm³), it is advisable to increase the separation between the nozzle and the base of the configuration for the PLA. With this extra space, it is ensured that the first layer is uniform and that the adhesion is not excessive, to avoid problems when removing the piece. In the same way, the distance between the supports and the base piece must be increased. In the field of printing temperatures, PETG requires higher but acceptable values for the vast majority of 3D printers in the current market (240-260 ºC extruder and 50-80 ºC base).

As can be seen from all the above, the PETG is a clear substitute for the PLA for users who seek to advance in the world of 3D printing with tougher parts and with good quality standards.

Related posts

Is your 3D printer compatible with advanced materials?

Color range of PLA Premium and CPE and its RAL and Pantone equivalence

inconveniente el PETG se ralla con mayor facilidad... En español, diremos que se RAYA si queremos denotar que se marca con Rayas en su superficie. No creo que nadie tome un rallador y se ponga a Rallar para una ensalada!! :)

Sería una buena prueba la del rallar el PETG como el queso :) Gracias por la corrección y nos encanta que gente como tú aporte su granito de arena para ayudarnos a mejorar. Intentaremos no pasarnos de la RAYA en futuros artículos!

Hola. Se le conoce algun disolvente al PETG, como ocurre con el ABS (acetona) y el PLA (éter, ***furano, etc...casi todos altamente cancerígenos, lastima!) Es una lata lijar, aunque llego a una buena calidad con pla lijandolo al agua!

No conocemos ningún disolvente que suavice el PETG pero si disponemos de un producto que alisa da superficie. Puede encontrarlo en el siguiente link.

Se puede cortar por laser

Other considerations: PLA is safer, biodegradable, and easier to use. PLA is available with a huge range of additives such as wood and metal. When my hippie wife starts in about my plastic footprint, I remind her that PLA is made from corn!