The following article tries to clarify the differences between the filaments of diameter 1.75 mm and 3 mm (3mm filament is the same diameter and 2.85 mm), a question that many users of 3D printing tend to have before acquiring a 3D printer.

Many professional and industrial 3D printers most use a Bowde System to reduce the moment of inertia, generated by the weight of the motors, on the axis of the HotEnd and thus have more printing precision) use 3 mm diameter filament.

One of the things that uses 3 mm and not 1.75 mm in this type of machines, is because the extruder motor has to work much less. Next we explain why:

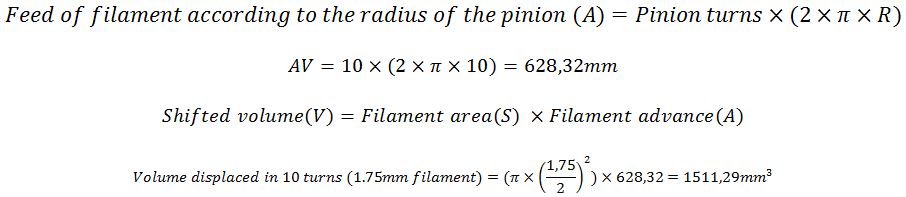

If it is assumed that under theoretical conditions a 3D printer with pinion moves a filament with a radius R=10 mm, turning 10 turns with a filament of 1.75 mm (for example PLA 1.75 mm) would displace 1511.29 mm³ of plastic volume. In order to move the same volume with a 3 mm filament (for example PLA 3 mm), the extruder pinion would only need 3.4 turns.

Now we do the previous operations in reverse order to obtain the turns that the same pinion of the motor of the extruder with a filament of 3mm must turn:

This reduction favors when making long-lasting 3D prints, since with the filament of 1.75mm the motors can get overheated by the rapid movements you need to do to push and retract the material, lose steps and ruin the entire piece that was to be printed. Another advantage of having less filament feed is that the pinion marks less amount of filament at the time of making the retractions.

Image 1: The length difference marked by the extruder motor can be seen to extrude the same amount of volume for the 1.75 mm and 3 mm filament

When using flexible materials (Filaflex or TPU) or fragile (Lay-Woo3D) the 3mm filament has the advantage of being more resistant to bending than the same filament in 1.75 mm. In addition, thanks to this resistance, the material remains more tense when winding it, which helps manufacturers to get coils with an almost perfect alignment and free of overlaps.

In the beginning, the filament was 3mm because of the ease of manufacturing it to that extent with an acceptable tolerance, but as technology has evolved, the large manufacturers of 3D printers have demanded the change to 2.85 mm (nº 4 inch) for being a standard measure in the world of industrial manufacturing, in which there are tools of this diameter and very accurate.

This change also favors the 3D printers with Bowden System, since these systems use PTFE tubes of 1/8" (3.175 mm) of inner diameter, so if a 3 mm filament with a tolerance of ± 0.05 is used (Beware of low quality filaments that may have areas of 3.2 mm) the material may slide very just through the PTFE tube, causing a high friction that will cause jumps in the extruder or even a total clog with low quality filaments that do not comply with the tolerance indicated by the manufacturer.

With the Direct System the filament is introduced in the HotEnd immediately and therefore this problem does not occur, regardless of the use of 2.85 mm or 3 mm. This measure of 3 mm is also favorable to use it with nozzle diameters larger than normal (0.8 mm, 1 mm, 1.2 mm or more) to be able to have a good control of material between the entrance and exit of the nozzle. As it is evident, with a nozzle of smaller diameter than usual (0.35 mm, 0.3 mm, 0.25 mm or less) the use of a 3 mm filament is an inconvenience to be forced to use a low extrusion speed, which can result in traces of material in the piece. In the previous case, the best option is to use a 1.75 mm filament that, in combination with small nozzle diameters, is possible to obtain very small and detailed models.

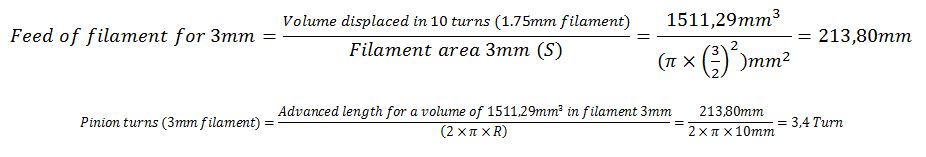

Image 2: Tumaker Voladora Bowden System

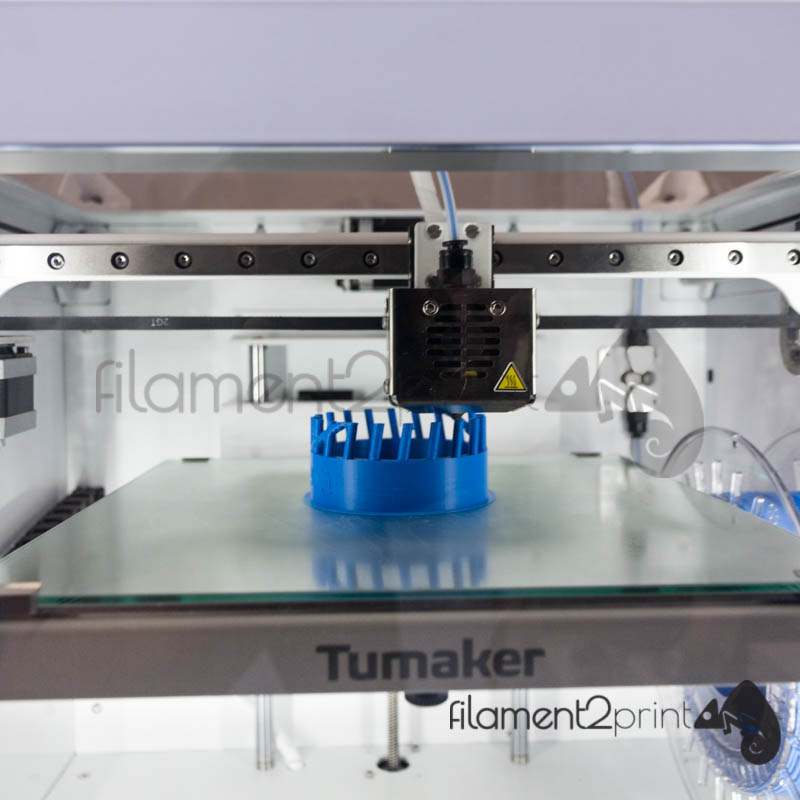

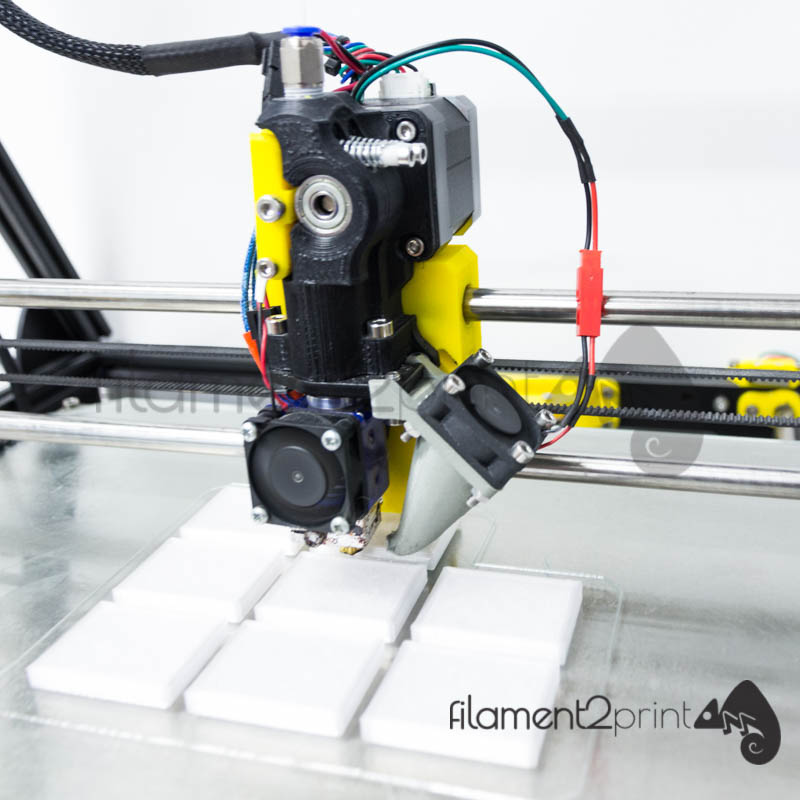

Image 3: Direct System Mendel Max XL

This diameter of 1.75 mm, having less resistance to bending, needs less pressure to be displaced by the extruder, which implies a simpler extruder design than for the 3 mm filament, simpler electronic components and can be used in any 3D printer with any type of extruder without great difficulty (not to be confused with any type of drive system).

As a final conclusion to this article and taking into account that it is not a trivial matter, we can say that the 1.75 mm filament is more suitable for non-professional use, with desktop 3D printes where 3D prints are often made for many hours or days. And on the other hand, the 3 mm filament is more suitable for professional o industrial 3D printers where 3D prints of even days are usually made, with large output diameters.

Bonjour, j'ai du mal à trouver des imprimantes qui impriment en 3mm. Quelles sont les marques ? Merci

Bonjour, Il existe un grand nombre d'imprimantes qui impriment un filament de 3 mm ou 2,85 mm de diamètre. Parmi les plus connues, les imprimantes 3D BCN3D ou les imprimantes 3D Ultimaker. https://filament2print.com/fr/filament-fdm/1181-bcn-sigma-d25.html

hola buenos dias aver si me puedes ayudar yo tengo una artillery x1 es para crear piezas grandes solamente aunque tengo que separar en varios trozos la pieza degustaría ahorra tiempo por lo que hablas hay entiendo mejor y mas rápido la de 3mm y que boquilla de 1,2 o cual seria la que me aconsejas gracias

Hola, Jesús. Si no nos equivocamos, la Artillery X1 trabaja con filamento de 1.75 mm de diámetro, y tiene un extrusor parecido al Titan Aero y un Hotend tipo Volcano. Gracias a esto, podrías utilizar un nozzle de 1 mm de diámetro de salida sin problema, pudiendo llegar incluso a 1.2 mm, lo que agilizaría las impresiones en gran medida.

Hola buen día, tengo una Anycubic vyper, soy nuevo en la impresión 3d y compre por error un filamento de 3mm, lo puedo utilizar? Tengo boquilla de fábrica de 0.4, o mejor hago el cambio ?