Cart

0

Product

Products

empty

No products

To be determined

Shipping

0,00 €

Tax

0,00 €

Total

Product successfully added to your cart

0 products in the cart 1 product in the cart

Quantity:

Blog

Discover the latest news, tips and tricks about 3D printing. We continually analyze and test new products and materials, in order to ensure the traceability and quality of our entire catalog, sharing our conclusions and our experience.

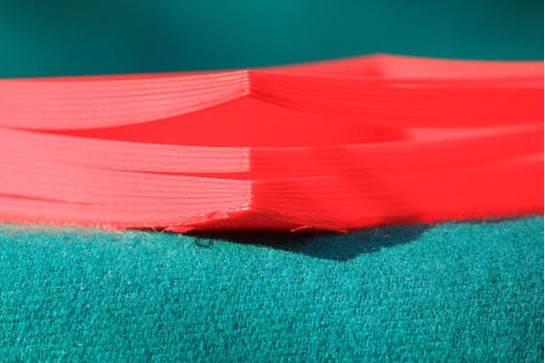

Shrinkage of parts in 3D printing and Warping

During printing, high-temperature extruded plastic undergoes volume shrinkage due to cooling. In some materials such as PLA this shrinkage is very low (between 0.3 % and 0.5 %), so it is not usually problematic, however other materials such as nylon 12 can have up to 2 % shrinkage or in the case of PVDF even up to 4 %, causing significant deformations in the parts.

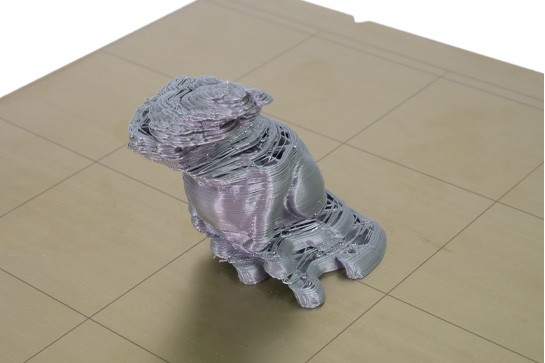

Small details and thin walls. Limitations of FDM technology

When designing and preparing parts for 3D printing it is very important to take into account the resolution limit of our equipment. It is advisable to avoid elements with a smaller size, as the printing quality of these elements will be very low and in many cases, the laminating software itself will omit them.

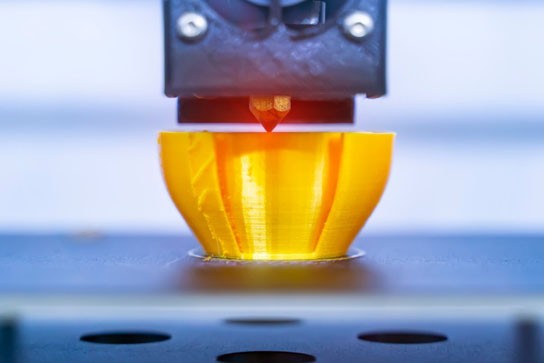

3D printing temperatures and optimisation

The printing temperature of a given filament depends not only on the type of material, but also on the printing conditions. Printing speed, nozzle diameter, extruder type or the distance between the extruder and the hotend have a considerable influence on the optimum printing temperature

Thermistors and thermocouples. Types and common problems

Thermistors are the most common and simplest sensor to implement, as they are connected directly to the printer board, while thermocouples are composed of a bimetallic junction that varies its conductivity depending on the temperature. This post explains the types on the market and the common problems with these sensors.

Speeds and accelerations in 3D printing

This post explains the importance of a correct configuration of the speed and acceleration parameters in 3D printing, in addition, the three parameters that define the speeds and accelerations in the movement of a FFF 3D printer for each of the 4 axes are mentioned and the most common elements on which the printing speed can be modified are explained.

Basic settings and maintenance of a resin 3D printer

LED-LCD-based resin 3D printers are significantly simpler than other technologies such as FDM or SLS. However, they also require regular calibration and maintenance.

3D printing with composite materials. What to have in mind

Filaments are often enriched with fibers or particles to achieve better thermo-mechanical, aesthetic or advanced specific properties. Fiber-reinforced filaments are abrasive, may be more brittle, may have different warpage and adhesion behaviors, and may require altered printing speed and temperature. All of these must be taken into account when choosing and maintaining printing equipment.

The supports in resin 3D printing

The use of supports in resin printing is always necessary. The parameters to be taken into account in their handling vary depending on the software, but the most common are: type, density, height, diameter and interconnection between supports. Modifying these values will solve possible problems that may arise in the printing process and post-processing.

Categories

Popular Articles

-

Common problems and solutions in 3D printing ene 15, 2020

Common problems and solutions in 3D printing ene 15, 2020 -

What is the flow of 3D printing and how to adjust it dic 13, 2017

What is the flow of 3D printing and how to adjust it dic 13, 2017 -

-

What is PETG? ene 16, 2019

What is PETG? ene 16, 2019 -

PETG vs ABS vs ASA feb 04, 2019

PETG vs ABS vs ASA feb 04, 2019