Additive manufacturing is the term used to describe the entire set of manufacturing technologies based on material contribution forming. This means that, unlike subtractive manufacturing (which encompasses traditional CNC machining methods), it is based on building parts by providing layer by layer the precise amount of material in a selective way.

However, within this category we can find a multitude of very disparate technologies, each with its advantages and disadvantages, so knowing its fundamentals and its limitations is something of great importance in order to select the most suitable one for each need.

Although there are many technologies and variants, the most common and widespread within the industry are three:

- Deposition of molten material (FDM)

- Selective photopolymerization of resins (SLA)

- Selective laser sintering (SLS)

Although the most widespread is undoubtedly FDM technology. Mainly due to the appearance of low-cost 3D printers based on this technology, in recent years both SLA and SLS technology have been gaining ground. Companies such as Formlabs or Sinterit market equipment, based on SLA and SLS respectively, capable of achieving industrial qualities at really competitive prices. This together with the appearance of new materials makes it currently difficult for a company or professional to opt for one technology or another.

Below we detail which are the main characteristics of each one, as well as their differences, advantages and disadvantages.

Fused Deposition Modeling (FDM)

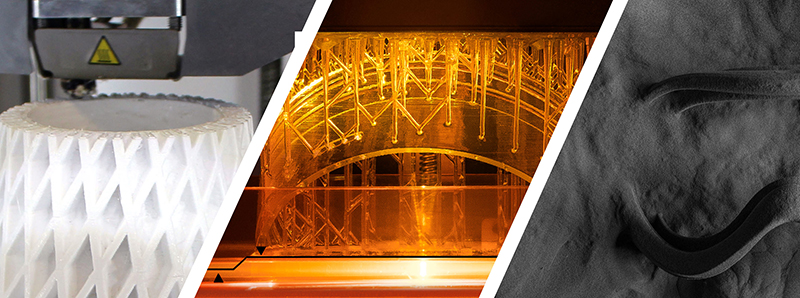

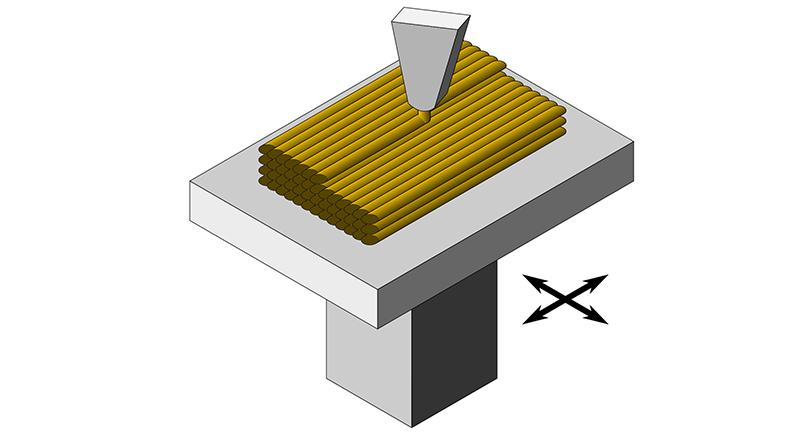

It is by far the most popular technology. It is based on extruding through a nozzle or "nozzle", a thermoplastic above its melting temperature. As the extruded material exits the filament nozzle it is selectively deposited and layer by layer to form the part.

Image 1: FDM Printing. Source: commons.wikimedia.com

Despite being the most common, it is the most complex when it comes to designing and preparing files for printing. The limitations of 3D FDM printing often determine the design itself, so in general, when parts are produced using this technology, it is necessary to design or redesign them to make them compatible. This can be a big problem when the goal of 3D printing is to validate models that will later be produced using other production methods.

Among all the limitations, the most important are the need to use supports and the impossibility of obtaining mechanical isotropy.

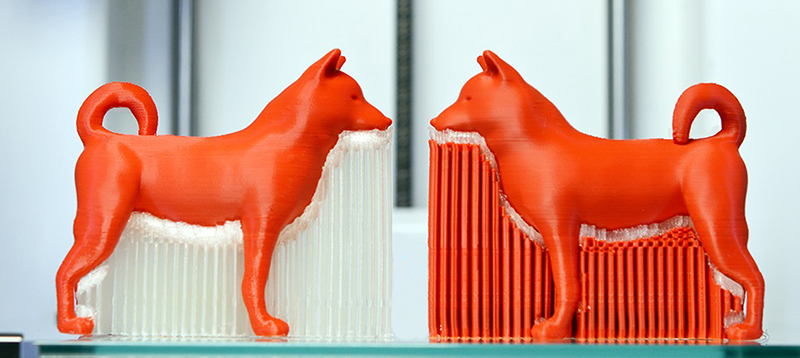

Since the molten material cannot be deposited in the air, it is not possible to directly print bridges or overhangs, so in these cases it is necessary to add support structures. This supposes a greater expense of material and time, in addition to the fact that the pieces will need post-processing to remove these supports and the surface quality in the contact area will be affected.

Image 2: Printed parts with supports. Source: Simplify3D

One way to minimize some of the drawbacks of using media is to print them using a soluble material. This will facilitate their removal and improve the surface quality of the contact area. This requires the printer to have a double extruder system such as the IDEX system for the BCN3D Sigma and BCN3D Sigmax printers or the Bondtech double extruder incorporated in the Raise Pro2 3D printers.

Movie 1: IDEX BCN3D system. Sourcee: BCN3D

On the other hand, as we explained in a previous article, using FDM is impossible to obtain isotropic parts, which is a major problem in certain mechanical and structural applications.

Other important limitations are low resolution and high tolerances. Although using small diameter nozzles it is possible to achieve Z resolutions close to those achieved by SLA or SLS, the XY resolution will always be much lower and will be conditioned by the material used. This is because the resolution is determined by the diameter of the nozzle used and not all materials are compatible with small diameter nozzles.

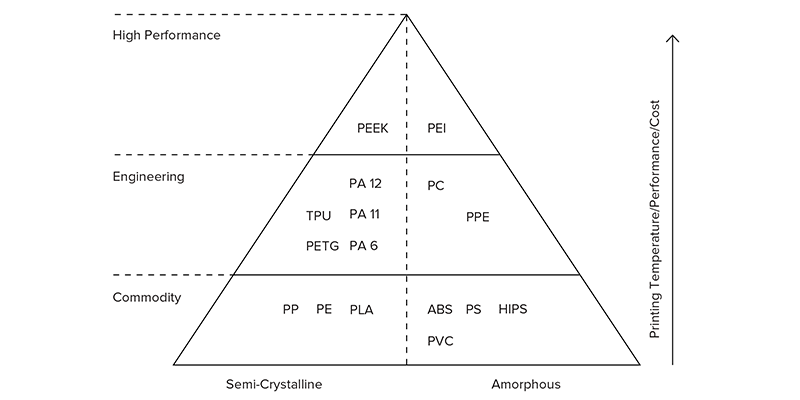

However, not all are disadvantages. FDM technology has, by far, the widest range of materials and at a lower cost, in addition to higher printing volumes and, although the price difference between the different technologies has been shortened, it is still the cheapest technology.

Image 3: Pyramid of the main materials available for 3D FDM printing. Fuente: 3dhubs.com

It is also a clean and safe technology that requires little preparation prior to printing. This allows it to be located in any environment and allows more immediacy than SLA and SLS printing that require more extensive preparation and cleaning tasks, making it the perfect technology for educational applications at any level, from elementary to studies superior.

It is an ideal technology for printing templates and tools, parts with a large medium volume or for those applications that require specific materials not available for other technologies.

Another sector in which 3D FDM printing offers great advantages is in the production of architectural models. In general, this type of project is made up of bulky pieces that do not require high precision. This, together with the availability of materials such as Filamet, Timberfill, Smartfil EP or PLA Mukha capable of providing metal, wood or ceramic finishes to the pieces without the need for post-processing.

Imagen 4: Modelo arquitectónico impreso por FDM. Fuente: Raise3D

Stereolithography (SLA)

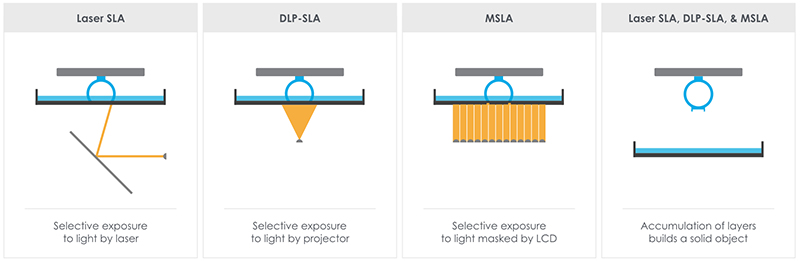

It is the second most common 3D printing technology. It is based on exposing a cuvette of photocurable resin selectively to ultraviolet light layer by layer. This selective exposure can be through a laser scan (SLA), a projector (DLP) or a masked led (LED-LCD / MSLA).

Image 5: Differences between SLA, DLP and MSLA. Source: theorthocosmos.com

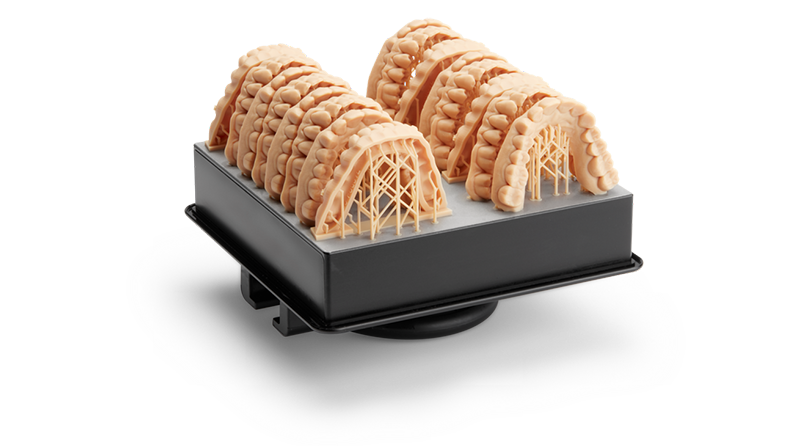

Like 3D FDM printing, it requires supports that must be removed after printing, however, 3D SLA printing does not currently allow simultaneous printing with two materials, so the only way to remove the supports is mechanically. This means that in this case the surface of the piece is also affected in those areas where there has been contact with the supports.

Image 6: Supports of a piece printed by SLA. Aource:3Dhubs.com

Another fundamental difference from 3D FDM printing is that it uses thermoset polymers instead of thermoplastics. In addition, SLA materials tend to be more expensive than FDM materials and have some toxicity. This, together with the fact that the pieces require cleaning and post-processing tasks, makes this technology less recommended for the educational sector.

However, its strength is high resolution and the excellent surface finish achievable through 3D SLA printing. In general resolutions of up to 50 um can be achieved in all planes.

Despite the fact that there are SLA printers with large printing volumes comparable to those of 3D FDM printers, in general 3D SLA printers tend to have considerably lower print volumes.

It is perfect for printing small parts that require high resolution and excellent surface finishes. It is currently the most popular 3D printing technology in the dental and jewelry industries. This is why it has the widest catalog of dental and castable resins.

Image 7: Dental models printed by SLA. Source: Formlabs.

Selective Laser Sintering (SLS)

It is probably the least known technology, despite being one of the oldest and most common in industrial settings.

This is because until recently all SLS 3D printing equipment used to require adequate facilities and the cost of both the equipment and the implantation used to be high. Although in recent years this has changed thanks to the appearance of SLS printers in desktop format, such as the Lisa and Lisa Pro printers, whose acquisition costs in implementation are close to those of the FDM and SLA systems. Although this technology allows the production of both thermoplastic and metal parts, as the objective of this article is to understand the differences between the three technologies, we will focus only on 3D SLS thermoplastic printing.

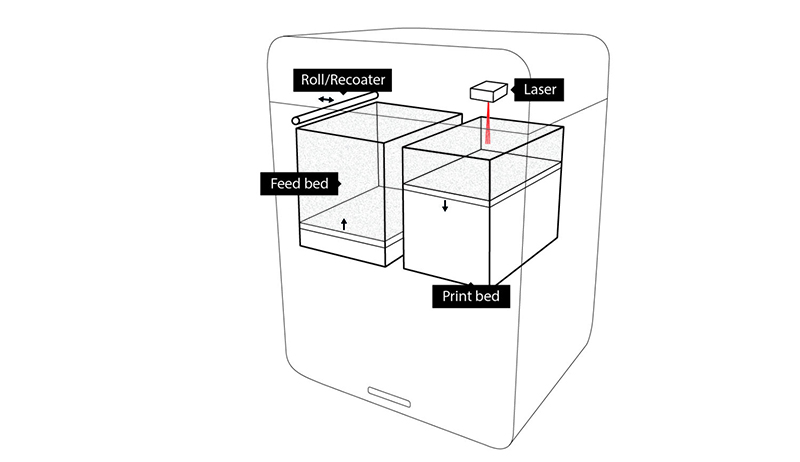

3D SLS printing consists of selectively sintering, using a laser scanning system, layers of powder material. Every time a layer is sintered, the build deck lowers and a special device called recoater applies a new layer of powder.

Image 8: Schematic of an SLS printer. Source: Sinterit.

The main advantage of this technology is the possibility of printing without supports. This makes the design constraints much less than in any other technology, in addition to greatly simplifying the post-processing of the parts.

This coupled with the high precision achieved by the laser, superior to that obtained by 3D printing SLA or FDM, makes it possible to print complex assemblies directly, without having to print its components individually.

Movie 2: Bicycle shift produced directly using 3D SLS printing. Source: Sinterit.

Another important advantage is that the parts printed by SLS are dense and have a high isotropy, which makes it the ideal technology for the production of functional models and prototypes. All this, together with the good surface finish, makes it also suitable for the production of small series of final products.

SLS 3D printers do not have a wide range of compatible materials as 3D FDM printing, however the possibility of using technical materials such as different types of nylons, or TPE and TPUs, makes it able to cover most applications.

Movie 3: Part printed on TPU using 3D SLS printing. Source: Sinterit.

Despite all the advantages, the main limiting factor of SLS 3D printing is the build volume. Although industrial equipment has large build volumes similar to that found in FDM systems, SLS desktop 3D printers have print volumes similar to SLA printers.

Also, although part post-processing is limited to cleaning to remove excess powder without sintering, SLS 3D printers require preparation and cleaning that make it less immediate than FDM printing.

Although all these characteristics have made this technology the industry standard, its high costs have limited its access to small and medium-sized companies. With the advent of affordable desktop SLS 3D printers like Lisa and Lisa Pro in recent years, this is changing. Although its cost is still slightly higher than equivalent models in FDM and SLA, currently cost is no longer a determining factor when choosing one technology or another.

Image 9: Sinterit Lisa Pro. Source: Sinterit.

Comparison between FDM, SLA and SLS

To properly compare the three technologies, we must do it at two levels: in terms of characteristics and in terms of design and manufacturing limitations.

The main characteristics of each technology are compared below:

Characteristics>Features | |||

|---|---|---|---|

| Feature | FDM | SLA | SLS |

| Operating principle | Extrusion of molten material | Resin photopolymerization | Sintered microparticles |

| Type of compatible materials | Thermoplastics | Light-curing resin | Thermoplastics |

| Amount of compatible materials | Very high | Medium | Low |

| Materials price | Medium - Low | High | Medium |

| Complexity | High | Medium | Medium |

| Immediacy | Very high | Medium | Low |

| Minimum layer resolution | 0.1 mm | 0.05 mm | 0.06 mm |

| Maximum resolution in XY | 0.25 mm | 0.05 mm | 0.08 - 0.08 mm |

| Precision | Low | Medium | High |

| Applications | Rapid prototyping. Education. Manufacture of templates and tools. |

Models with small details. Castable negatives for jewelry and dentistry. Splints. |

Functional prototypes. Short series. Templates and tools. Orthopedic components. Medical models |

| Advantage | Low price. Immediacy. Materials available. |

High resolution. Quality dental and castable materials. |

Print without supports. High quality parts. Print assemblies directly. High accuracy. |

| Disadvantages | Need to use supports. Some materials have high shrinkage. |

High cost of materials. Low print volume. |

Long printing times. Low print volume. |

The following table shows the design limitations of each technology:

Design requirements | |||

|---|---|---|---|

| Feature | FDM | SLA | SLS |

| Overhangs | Requires supports from 45º | Always need supports | Never need supports |

| Bridges | Requires supports from 10 mm | Does not need supports, although they are recommended | Never need supports |

| Minimum wall thickness | 0.8 mm |

0.5 mm on supported walls 1 mm on unsupported walls |

0.7 mm |

| Engravings |

0.6 mm wide 2 mm high |

0.4 mm | 1 mm |

| Minimum diameter of holes | 2 mm | 0.5 mm | 1.5 mm |

| Tolerance on moving parts and connections | 0.5 mm | 0.5 mm |

0.3 mm in moving parts 0.1 mm in connections |

| Exhaust holes in hollow parts | No necesita | 4 mm | 5 mm |

| Minimum detail size | 2 mm | 0.2 mm | 0.8 mm |

| Minimum column diameter | 3 mm | 0.5 mm | 0.8 mm |

| General tolerances | ±0.5% (lower limit ± 0.5 mm) | ±0.5% (lower limit ± 0.15 mm) | ±0.3% (lower limit ± 0.3 mm) |

Today, computers based on these three technologies are available on the market in a similar price range, such as printers from the manufacturers Raise3D, Formlabs or Sinterit. Thanks to this, the only criteria when making the decision to implement one technology or another will be technical criteria.

It is necessary to assess well the needs and the use that will be given to the 3D printer to decide which technology is the most suitable and to be able to make the investment profitable.