Designing has never been so easy, thanks to the introduction of 3D printing technology. If you can imagine, you can create just as you imagined. This technology has allowed us to make important advances and reduce costs in an infinite number of sectors such as construction, automotive and medicine.

Although with conventional technologies you can make quality and attractive designs for users, 3D printing goes further with the creation of amazing models, even the most complex designs can be printed and used without problem. With some expert advice, any user can also create quality 3D prints. The following five guidelines are a good start to achieve the quality desired by all.

Adjust the layout for 3D printing

This step is the most critical step for anyone who uses 3D printing to make mechanical or assembly equipment. 3D technologies are not as accurate as other technologies, although no machine is 100 % accurate. For this reason, it must be ensured that all the parts that you want to use for the design have the proper separation so that they fit perfectly together. In the case of a part that fits into a bearing, a hole that is slightly larger than the bearing must be created in the 3D model to compensate for the deviation that the 3D printer will have, which may be greater or lesser depending on the type of 3D printer printer used. Once the deviation is adjusted, the modifications must be included in the final design.

Image 1: Inflator made with 3D FDM printer. Source: BCN3D

Use support structures when necessary

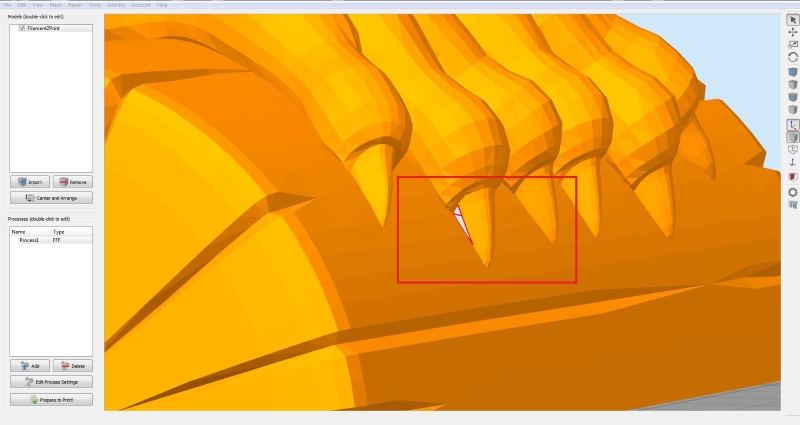

Most 3D printing technologies make the pieces layer by layer. This makes the structures that have to be suspended in the air a little weak or separated from the rest of the piece. With the use of support structures, these defective parts are avoided, giving the design its real shape.

Each type of 3D printing technology requires different types of support. For SLS, the powder used also serves as support, while FDM and resin technology (SLA, DLP, LED...) always requires a support structure generated in the process of rolling the piece. The type and amount of support will depend on the model that is printed and the technology used.

As a general rule, to avoid the use of support structures, be sure not to use overhangs greater than 45°. This reduces printing time, post-processing time and material waste.

Image 2: Piece with support. Source: Polymaker

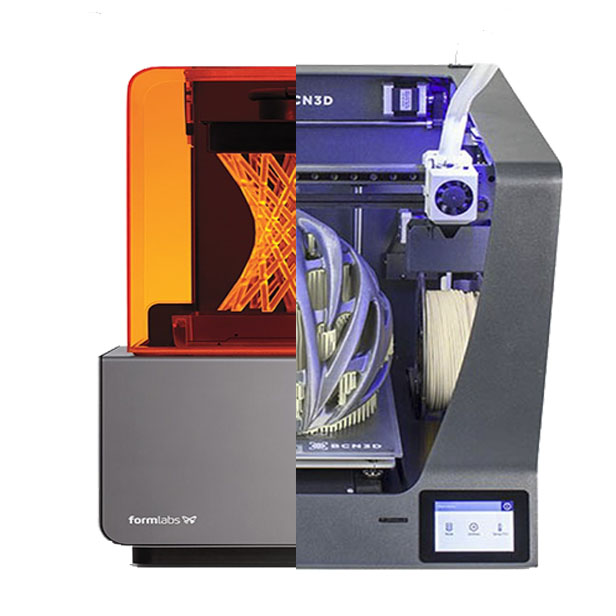

Always use files with high quality

For a model to become a 3D printed part, it must be converted to a file that the printer can use. The quality of the file is a key point to ensure that all design details are included in the print. In the case that the quality of the file is low, it is very likely that certain details are not included.

To ensure that the lamination software is accurate, the model must be completely closed, avoiding surfaces that are not in contact, in short, make sure that the model is completely airtight. Finally, the model must be scaled before exporting to ensure that no details are lost in the subsequent scaling process. This step is even more critical when performing a group of parts that belong to the same model.

Image 3: Open area

Know how 3D printing works

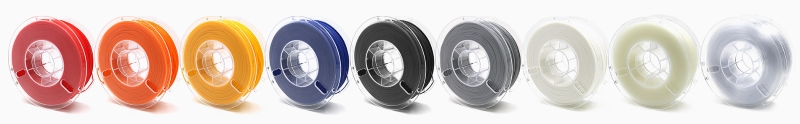

Knowledge is power, especially when using 3D printing technology. This technology is sometimes more complex to understand because it combines several already complex systems. Understanding how 3D printing technology works is key to knowing the advantages and limitations, and also, speed up the production process.

The three most common 3D printing technologies are: FDM, SLA / DLP / LCD and SLS. All three have their advantages, disadvantages and the most favorable applications. For example, SLS is more effective for complex geometric designs and will not necessarily need much support. SLA / DLP / LCD is ideal for fabrications where fine details and really small parts are required, while FDM is perfect for making small and medium sized pieces while maintaining good quality.

Image 4: Impresora SLA vs FDM

Pay attention to the type of material being used

Each material used in the design has different characteristics that work uniquely with 3D printing technologies. Once the operation of 3D printing technologies is understood, more accurate decisions can be made about the materials that should be used for each application. Each user should pay attention to the manufacturer's instructions to be sure that their 3D printer meets the requirements necessary to use each material. Most manufacturers will specify all the necessary parameters to be able to print without problems: temperatures, speeds, layer heights, laser exposure and etc.

Image 5: Variety of materials for 3D FDM printers. Source: Raise3D

Conclusion

The simple tips cited above give any user the basic day-to-day knowledge to make quality 3D prints without the need to control an infinite amount of technical information about all the technologies and materials on the market.

Article in collaboration with Geomiq.