When the term "the spool has a knot" is used in 3D FDM printing, it is totally wrong and we will explain why.

Making a knot manually without releasing the filament is totally impossible. Any user can perform the test, must take a thread, a bobbin and wind manually. During the process you should try to make a knot, something impossible without releasing the filament. Now the user must think that producing something similar during the winding of a filament (in the factory) is unlikely because he would have to pass the winding machine under the extruder.

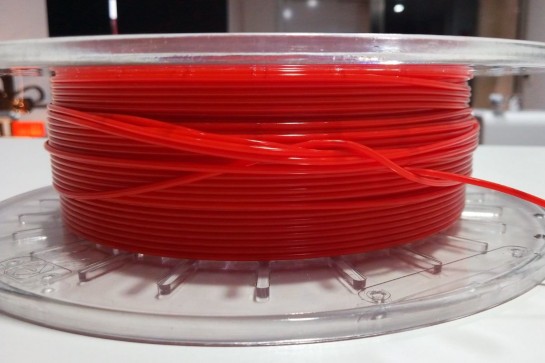

Given the above and demonstrated that a knot cannot be produced in the filament production process, what can happen is an overlap. The winding process is complex, since the winding tension and the correct lateral positioning of the filament are involved. If the filament turns are not positioned correctly during the winding, there is a high probability that in the last turns of the spool one of these threads will slide towards the bottom of the spool, occupying an available gap, becoming placed 1 or 2 levels below what would apply. This causes that when unwinding during a printing, that turn is subjected to the pressure of the upper turns and does not rise to the outside, causing an overlap that will cause the printing to fail, since the extruder will reach a point that cannot throw more through the filament.

Overlapping occurs more easily in filaments with a diameter of 1.75 mm than 2.85 mm, since the larger diameter makes it difficult to move between levels. The user must take into account that the overlap only occurs at the beginning of the spool, never by the middle or the end, although it may be the case that the problem is dragged to the last layers.

Currently, the main filament manufacturers do not show this problem by having a device that controls the winding at all times. A stepper motor, which is responsible for positioning the filament, is continuously communicated with the motor that rotates the coil, resulting in a device that ensures that the pressure and position of the filament is correct, avoiding overlaps.

Overlaps, incorrectly designated as nodes, are caused by the user action of the 3D FDM printer. The plastic materials have a memory effect, trying at all times to recover the way in which they were manufactured, cause that when releasing the filament of the reel, it tries to wind itself. During the handling of the spool, when introducing and removing the filament from the 3D printer, there is a great possibility that the end of the filament passes over or under one of the turns, overlapping. To try to avoid this problem, when introducing or removing the filament from the 3D printer, the user must always keep the filament tensioned and carefully wind.

From the Filament2print team we always recommend using quality filaments, which are free of any overlapping and of factory-originated geometric imperfections. With this and following the instructions in the previous paragraph, all users of a 3D FDM printer will eliminate the problems of overlapping (badly called a knot) in the spools.

Ceci est faux : Même si c'est rare, il est parfaitement possible d'avoir un nœud si on ne fait pas suffisamment attention quand on ré-installe une bobine déjà entamée. Quand on retire le fil de l'extrudeur, sa rigidité fait qu'il a tendance à s'échapper et à se rembobiner comme un ressort. À ce moment là, il existe un risque qu'il passe sous d'autres spires et si on ne s'en aperçoit au moment de le ré-installer, un nœud est parfaitement possible.

En effet, cela peut arriver, mais ce serait toujours un chevauchement. Un nœud, par définition (voir image 1 du post), est impossible à réaliser sans libérer le filament, il est donc impossible qu'il se forme lors de l'impression.

Bonjour, contrairement à ce qui est écrit, un chevauchement peu se produire en cours de bobine, c'est actuellement mon cas pour une bobine utilisée à environ 75%. Effectivement, à part surveiller de près le dévidement de la bobine en cours d'impression, je ne vois pas d'autre solution simple de contourner ce problème. J'envisage de faire un petit bidouillage pour mesurer la tension sur le fil avec une alarme pour ne pas rester collé à l'imprimante pendant des heures.

Le chevauchement, le nœud....... C'est quoi une NOEUD DE CABESTAN ? Et si vous voulez jouer sur les mots .. Ce que vous démontrez dans la première image, ce n'est qu'un Demi nœud ....... Donc oui le chevauchement peut très bien être un nœud. Il est tout à fait possible de faire des nœuds sans libérer le filament.. (le courant en terme de noeud, le dormant étant sur la bobine). En plus la vidéo de démonstration est truquée car elle s'arrête et reprend toujours à 75% d'une passe complète. en regardant de prêt comme par hasard c'est du côté ou il y a un défaut dans l'embobinage.... avec de fortes chances de soucis de ce côté la, à n'importe quelle endroit de la bobine.