In the world of 3D printing FDM/FFF has been for a few years a family of materials that clearly stands out above all, the family PAEK (polyaryletherketone or polyaryl ether ketone). The materials that belong to this class are semi-crystalline plastics, which resist high temperature (near 200 ºC) maintaining high values of mechanical resistance.

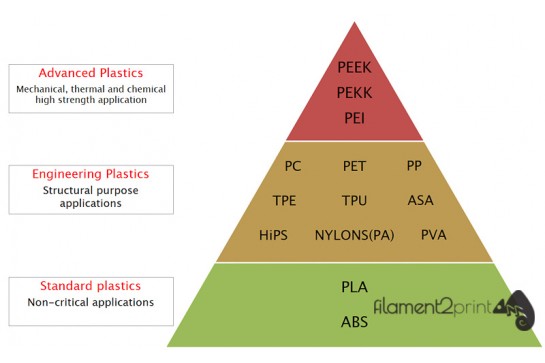

Within the PAEK family exists the PEEK, the PEKK and the PEI (ULTEM 1010 and ULTEM 9085). All these have high mechanical strength, chemical resistance and high flammability temperature.

PEEK filament (PolyEtherEtherKetone)

The PEEK (PolyEtherEtherKetone) is the most crystalline of the three materials. This indicates that it has the highest values of mechanical strength of all (without taking into account alloys with carbon fiber). But this presents a problem, because the molecules follow a pattern of repetitive ordering in the three dimensions of space in the solid state, it is more unstable at the time of melting. This implies a high difficulty of using the PEEK filament in 3D printing even for expert users with advanced 3D printers.

PEKK filament (PolyEtherKetoneKetone)

PEKK (PolyEtherKetoneKetone) has a semicrystalline structure (less crystalline than PEEK). This type of structure appears when a material has two clearly defined regions, an amorphous and a crystalline one. This structural condition offers an increase in the ease of printing (lower crystallization rate) maintaining similar resistance values and even higher than those of the PEEK.

The PEKK stands out above the PEEK in its resistance to compression, being up to 80 % higher. In addition, this type of filament has a chemical resistance to a huge amount of fluids: halogen hydrocarbons (benzene), automotive fluids (coolant), alcohol and aqueous solutions (sea water).

Applications of the PEKK

The use of PEKK is highly widespread, from medicine to military applications. Its potential is such that even NASA uses this material in the 3D prints it makes in outer space. In medicine some development centers have created knees, hips and other types of functional implants with a resounding success in their patients. The union of all its advantages has helped the development of light, resistant and anti-reflective military helmets to avoid being discovered by the light emitted by an enemy lantern. Finally, large aeronautical companies use the PEKK to make functional pieces for their aircraft.

PEI filament (ULTEM 1010 and ULTEM 9085)

The PEI (ULTEM 1010 and ULTEM 9085) is the most modified material within the PAEK family, even coming to have the designation of resin by experts in the field. The thermal resistance of this material is one of the highest in the field of 3D printing FDM/FFF, having a glass transition temperature of 215 ºC and a maximum constant working temperature with a pressure of 0.45 MPa of 200 ºC

The advantage of PEI is that at these temperatures the mechanical properties hardly change. This is because its great dimensional stability maintains the structural shape even when raising the temperature, something unthinkable with the majority of existing materials in 3D FDM/FFF printing.

Applications of the PEI

The ULTEM 1010 is commonly used to make short cycle injection molding tools, carbon fiber lamination tools and other types of molds that are subject to high pressure and temperature values (Autoclave). Within this type of high strength molds are those used for the vulcanization process of plastics, such as rubber. Thanks to PEI ULTEM 1010 molds can be made faster, easier and cheaper than current steel molds. On the other hand, the ULTEM 9085 is the revelation material of the aeronautics industry. Its thermal resistance, chemical resistance, resistance to breakage and high performance make it possible for this material to meet the most stringent testing and traceability criteria required by the aerospace industry and the regulatory agencies of the certificates.

Continuous innovation in the improvement of materials

Large filament manufacturers such as French Nanovia have revolutionized the market by improving both PEKK and PEI (ULTEM 1010) with carbon fiber. Carbon fiber is a pseudo-amorphous material that offers these materials a lower melting point, slower crystallization and maintains the high crystallization temperature (Tg= 160 ºC), this translates into an increase in the ease of printing. Besides, this union also enhances the structural stability, improving the mechanical properties. For all the above, the PEKK CF and the PEI CF have earned a place in the category of the most powerful and easy to use materials within 3D printing FDM/FFF. In addition, these two materials compete on a general level with the thermoplastics most used in the engineering industry (polysulfones, polyphenylene sulphides and polyketones).

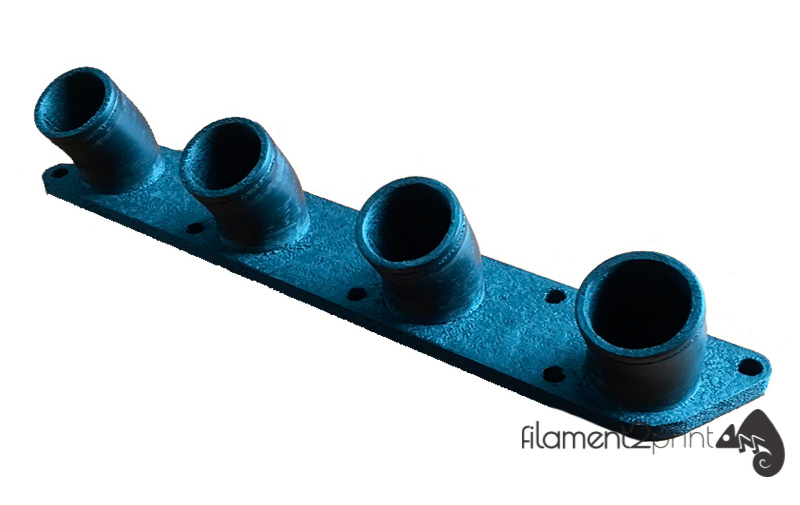

Image 2: PEI CF. Source: Nanovia

Requirements for the use of PAEK Materials

Finally we must mention that the use of these advanced materials is for experienced users with advanced technology 3D printers. The minimum requirements that a 3D FDM/FFF printer must have to use these materials are: Extruder temperature 370-400 ºC, base temperature higher than 150ºC, chamber temperature higher than 80 ºC. These values are necessary due to the sensitivity of structural deformation in contact with air zones at different temperatures of these materials.

The final conclusion is that all materials belonging to the PAEK family (PEEK, PEKK, PEI, PEKK CF, PEI CF) are at the top of industrial use thanks to their high flammability temperature, their chemical resistance, their resistance mechanical and its good strength/weight ratio.