Users of desktop 3D printers (FFF/FDM) can often find various types of problems, which may be due to poor filaments, improper printing parameters, poorly-suited conditions for the location of 3D printers (like humid environments, cold or drafts) and lack of maintenance, and calibration of the 3D printer.

One of the most important parts to calibrate in a 3D printer is the base or bed, because if it isn´t well leveled, you will not get good printing results.

This bed calibration process, depending on the 3D printer model, can be in the following ways:

- Auto leveling assisted: Some 3D printers have this system, which consists of a height adjustment by turning the screws of the base and with the help leds that have the own 3D printer, which change color red to green at the right height.

- Compensating leveling: The 3D printer makes an initial measurement, by points, of the distance between the extruder and the base. Then, at the time of printing, the z-axis varies the height, in the same layer, to keep the distance between the extruder and the base always constant.

- Manual leveling: Adjust the leveling of the bed by turning the screws of the bed itself.

In this article we will focus on the case of manual leveling, being the most common in the majority of FFF/FDM 3D printers on the market.

Initial recommendations

If the 3D printer has a glass base and we use some fixing spray (like Magigoo, 3DLac or DimaFix), it is advisable to wash the base well to avoid possible problems when leveling it. It is also vital to remove any remaining filaments hanging from the nozzle, otherwise, we will have a measurement error produced by that material sediment.

On the other hand, the regulating screws of the base itself must be placed at the midpoint of its travel. In addition, when performing the z-axis "home", the z-axis limit switch should be moved, increasing the distance between the base and the extruder, to avoid possible contacts or even breakage of the glass or any printer support 3D.

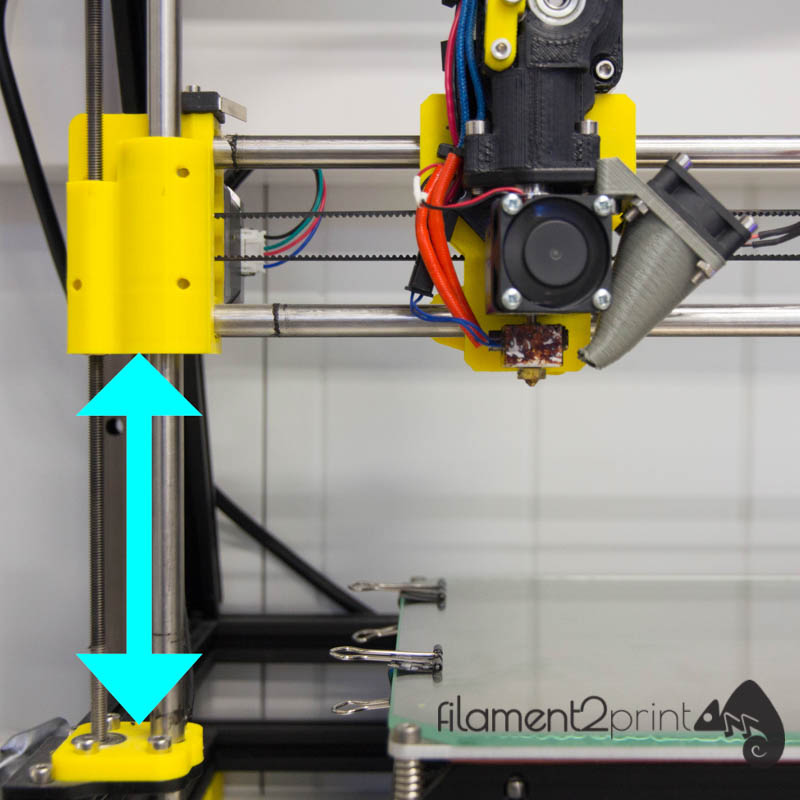

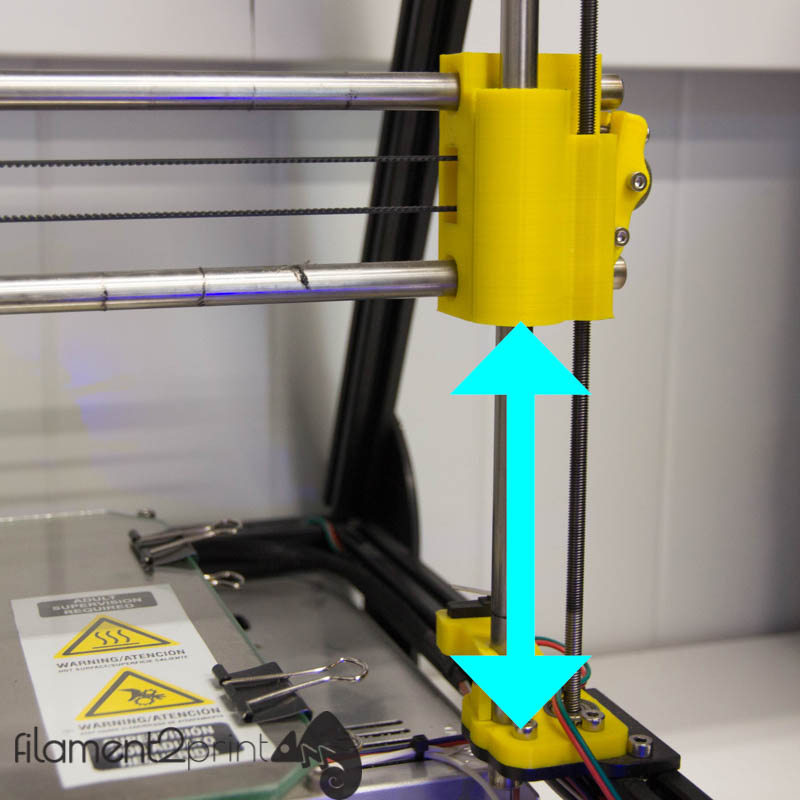

X-axis adjustment

It is necessary to adjust this axis (which is where the extruder moves itself) so that when the extruder moves, there are no variations in height between the extruder and the base. To begin, you should check that the height on both sides is the same, measuring from a point in the z axis guide to a fixed point of the 3D printer. To equalize it, the motor is manually turned on the side that needs to be adjusted, holding the other side so that it doesn´t rotate. If we don´t do this, and because the z-axis motors are connected in parallel, by rotating one, it would generate electricity and spin the other.

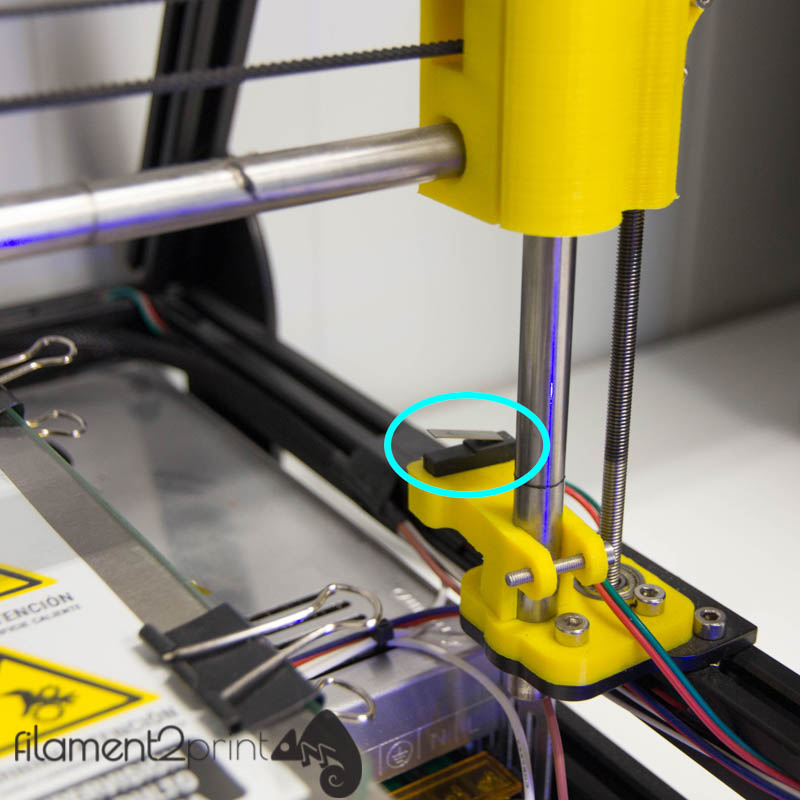

Adjusting the z axis limit switch

For this step, if the 3D printer does not have assisted leveling, 3D printing programs such as Cura3d or Pronterface will be used, which have a wizard to do "home" in z or directly a basic leveling section. The software moves the z-axis and adjusts the limit switch manually until the tip of the extruder is very close to the base.

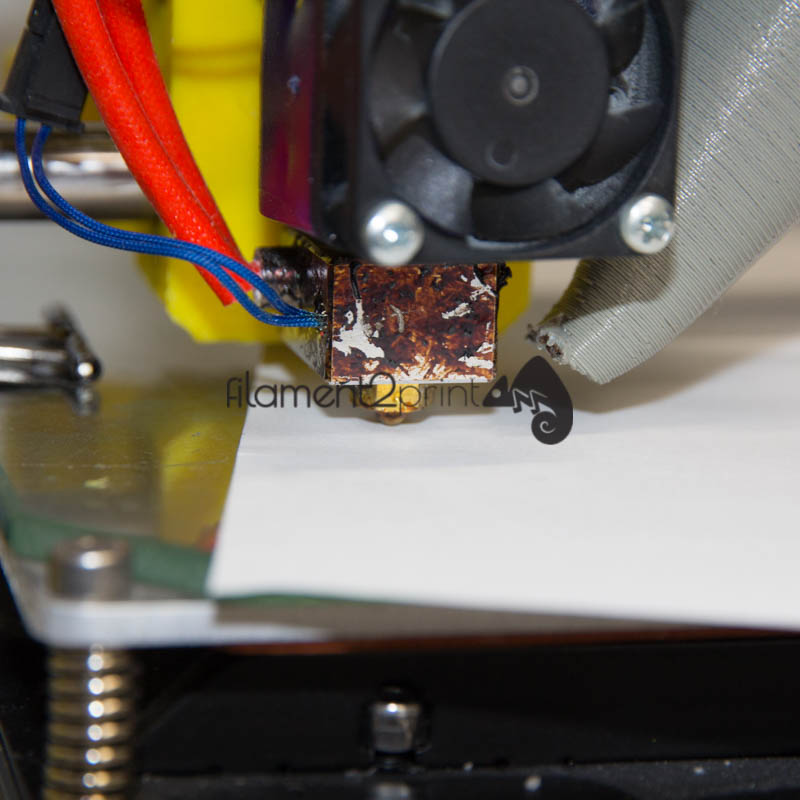

Adjusting the corners of the base

In this step, the outlet diameter of the nozzle must be taken into account. The ideal height is always half the exit diameter. That is, if the 3D printer has a nozzle of 0.6 mm, the ideal height would be 0.3 mm. For this distance to be exact, a gauge of that thickness, or in its absence, will be used, and since most 3D printers use a 0.4 mm nozzle, an 80 g sheet having an approximate thickness of 0.2 mm. Insert the sheet between the tip of the extruder and the base, and lower the z axis to the "home". The height will be correct when the folio is not completely free, nor is it tensile, but when it is noticeable to rub the sheet of paper with the nozzle.

To adjust this distance the screw is turned one way or the other, depending on whether the base needs to be raised or lowered. This process must be carried out in the vicinity of the leveling screws of the base itself as often as necessary to achieve the ideal height.

Z axis limit switch.

Ideal distance between nozzle and base.

Just by taking a few minutes to perform these steps of leveling the base, will avoid many printing problems.

Cuanto cuesta el calibrador para impresora 3D, espero una respuesta, Saludos

¿A que te refieres concretamente con "el calibrador para impresora 3D"?

Saludos y gracias por compartir

Muy buen post, sobre todo porque la información que entregas es muy relevante saludos Nicolás

Hola. Sigo tus pasos, pero luego de hacer la 4ta esquina , reviso los siguientes puntos nuevamente y ya no se encuentran nivelados, continuo nivelando y se desnivela el siguiente y así de forma indefinida. ¿Alguna idea que puede ocasionar esto? Gracias

Hola Mauricio.

De ser así posiblemente deberías revisar la planicidad de la base. ¿Qué sistema de base tienes en tu impresora 3D?

También pasé por el mismo problema, después de ajustar la altura individual de cada elemento de la mesa, lo revisé y todos estaban fuera de posición. Repetí el mismo paso de ajuste 4 veces, a partir de entonces las alturas ya no cambiaron.

Não tenho lido nada a respeito de ajustar a altura da mesa quando se tem,um vidro de espessura maior do que o limite imposto pelo curso dos reguladores da mesa de impressão. Após 3 meses sem utilizar o vidro de 4mm que comprei, notei que a solução seria reajustar o fim de curso Z, levantando o mesmo aproximadamente 1 mm, no meu caso foi suficiente. Há pouca ou nenhuma literatura sobre esse ajuste.

Hola buenas noches tengo un problema que empieza a imprimir llega un momento en que es como que el extrusor empieza a chocar la pieza y termina empezando a mover el vidrio para todos lados puede ser por la calibración

Hola Lucas, puede ser un problema de warping. Cuando la adherencia con la base no es buena o si la pieza es muy grande, al contraerse tienden a levantarse las esquinas y chocar con el extrusor. Puedes usar algún producto de los que tenemos disponibles para mejorar la adherencia.

Hola yo tengo el problema que durante el desarrollo de la impresión la base de calibración manual se descalibra y hace que la impresión se arruine

Cuando pongo para imprimir el se va a una punta y no en el centro alguien me oyede ayudar . ya que soy nuevo en esto gracias. es una geeetech i3 prob

Hice todas las calibraciones, y el cubo de calibracion me da 17mm en eje x, y (en ambos ) siendo el cubo de 20mm x 20mm - el eje z me da ok los 20mm.. las correas estan ok y ya calibre los pasos/mm . de acuerdo alr esultado del cubo que es lo que podria estar faltando revisar ?

Estoy por adquirir mi primera impresora 3D, hago diseño de piezas mecánicas, es muy importante la diferencia entre una impresora con calibrado de paralelismo automático o manual? vale la pena gastar más sólo por tener el calibrado automático? Gracias!

Hola, Daniel. El calibrado automático te va a ofrecer una mayor garantía de que la primera capa queda perfecta. Una primera capa óptima es muy importante y afecta a la calidad del resto de la pieza, a la adherencia del material y, en definitiva, al resultado final. Además, te ahorra tiempo en el proceso de impresión. Sin embargo, también se pueden conseguir los mismos resultados con una impresora 3D con nivelado manual. Esperamos haberte ayudado.

Tengo una impresora voxelab próxima, ya la calibre, ya revise la resina y ya luche por qué reconociera los archivos, pero simplemente no imprime nada. No sé si sea por la resina que utilizo u otra cosa, estoy desesperado