FDM/FFF 3D printing is one of the most widespread technologies currently on the market in the 3D printing segment. FDM printing (Fused Deposition Modeling) consists of driving a plastic filament through an extruder that melts it above its melting temperature and deposits it layer by layer on the printing surface, increasing the height of the part until it is completed.

After the 3D modelling phase, a process through which a 3D representation of an object is achieved, it is necessary to carry out a second phase, where, through a lamination programme, the object created with the modelling software is divided into a series of layers. Subsequently, a series of orders are generated indicating to the 3D printer what movements it should execute, where and how it should deposit the molten material to form the final part. The code generated by these lamination programs is known as G-Code.

Below is a compilation of the 5 best free laminating software for FDM 3D printers:

Ultimaker Cura

The Ultimaker Cura laminator is a free software with a simple interface for 3D model preparation and host functions on filament 3D printers.

Image 1: Ultimaker Cura software. Source: Ultimaker.

Ultimaker Cura is one of the most popular and widely used slicers today, as it offers a low level of difficulty, is versatile and open source. This slicing software developed by Ultimaker stands out thanks to the fact that the code it generates is compatible with countless printers on the market, it is free, has an easy to understand and use interface and supports STL, OBJ, X3D, GIF, JPG, PNG and BMP file formats. It also contains pre-programmed profiles for less experienced users.

PrusaSlicer

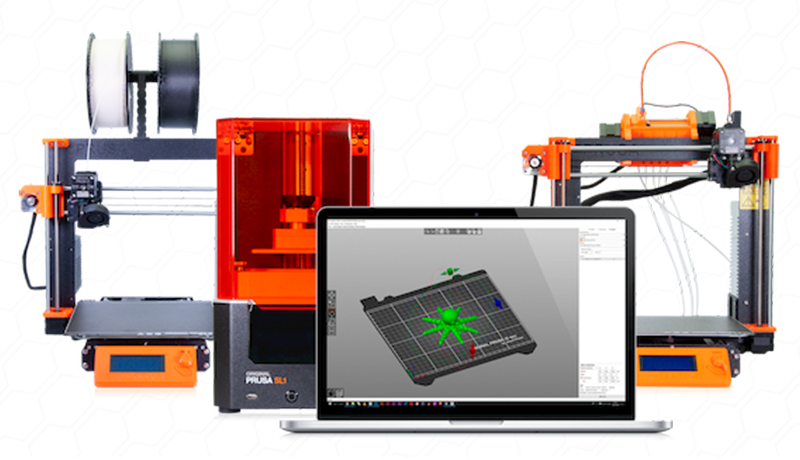

The PrusaSlicer laminator, formerly known as Slic3r Prusa Edition or Slic3r PE, is a lamination software developed by the renowned FDM 3D printer manufacturer Prusa. This software is an open source tool and is constantly being updated and developed.

Within the laminator itself, up to 3 lamination modes can be selected: simple, advanced and expert. Each of these levels is focused on the level of experience that each user has in the field of 3D printing, and will allow a series of parameters to be modified in each of the modes.

Image 2: PrusaSlicer interface. Source: Slic3r.

Some of the outstanding features of the PrusaSlicer software are the possibility of modifying the layer height automatically, either to reduce the time or to improve the finishes or the possibility of generating pauses in the code to be able to change the filament colour easily to the desired height.

One of the biggest headaches when it comes to 3D printing is the configuration of the printing parameters so that it is carried out correctly. This software has preconfigured profiles to print the models safely without having to modify any parameters. Therefore, it is the ideal option for those users who are new to FDM 3D printing. However, thanks to its advanced mode and the possibilities it offers, it is also an ideal software for experienced users.

In addition, each update of this software includes new profiles for 3D printers and materials that are coming onto the market, even from other brands.

IdeaMaker

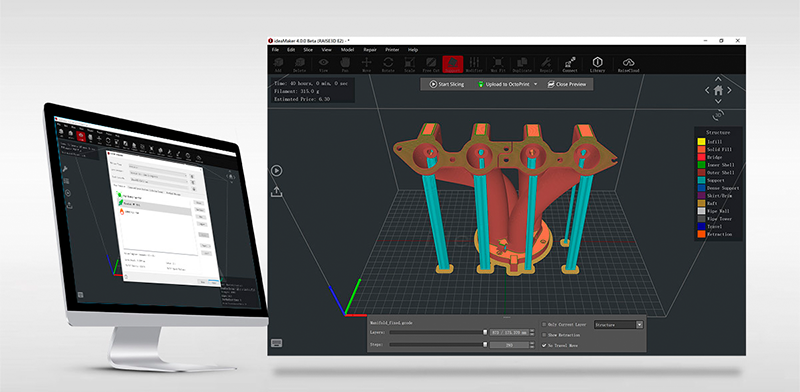

Just as Prusa or Ultimaker 3D printers have their own laminating software, Raise3D also has its own: IdeaMaker. Like the previous laminators, IdeaMaker is not exclusive to Raise3D printers, but is compatible with third-party 3D printers.

Imagen 3: Interfaz de IdeaMaker. Fuente: Raise3D.

IdeaMaker is a free software with great potential that will allow the user to configure the 3D printing parameters that best suit the process, being able to use customised supports and varying the layer height, speed and quality. It also has innovative options such as the texture applicator.

In addition, to speed up the 3D printing process, users can send files directly to RaiseCloud to manage and monitor the printing process. To use RaiseCloud, the 3D printer must be connected to an Octoprint server.

With all these functionalities, more and more users are opting for this laminating software, which is also constantly being updated to offer new features.

IceSL

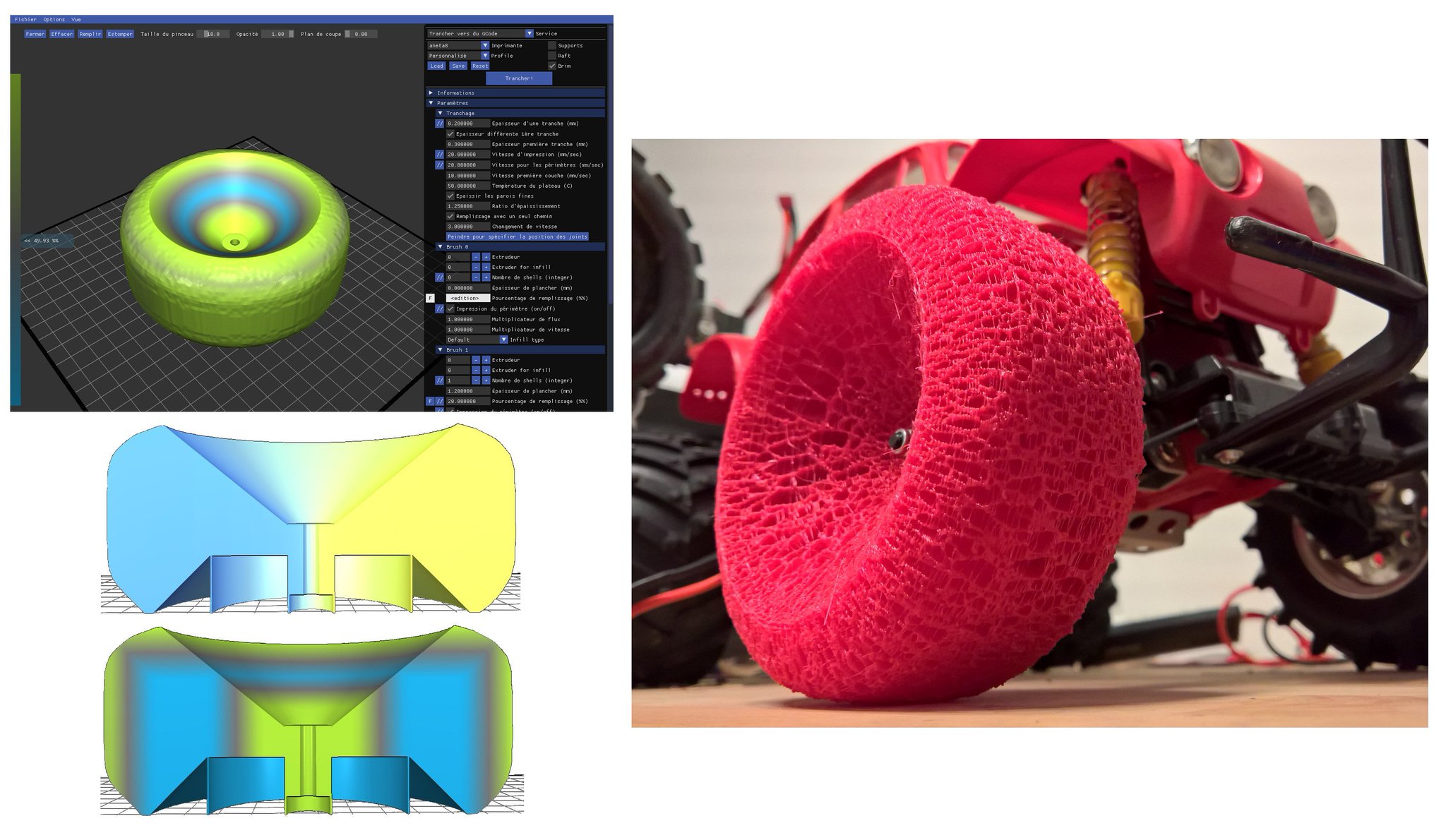

IceSL is not only a 3D laminating software, it is also a 3D modelling tool. IceSL has three versions with different functions:

- IceSL-forge: a software that combines modelling and cutting and provides the user with great flexibility. Modelling is done from Lua-based scripting language.

- IceSL-slicer: a comprehensive slicing software with a number of innovative options such as progressive fill.

- SliceCrafter: an online slicing software. The latter is less powerful than IceSL-slicer, but runs entirely from the web browser, so we can use it from anywhere without installation.

Image 4: IceSL interface and 3D printed part. Source: IceSL.

There is no doubt that the different versions offered by this software adapt to the needs of many users and allow complex operations to be carried out in a simple way.

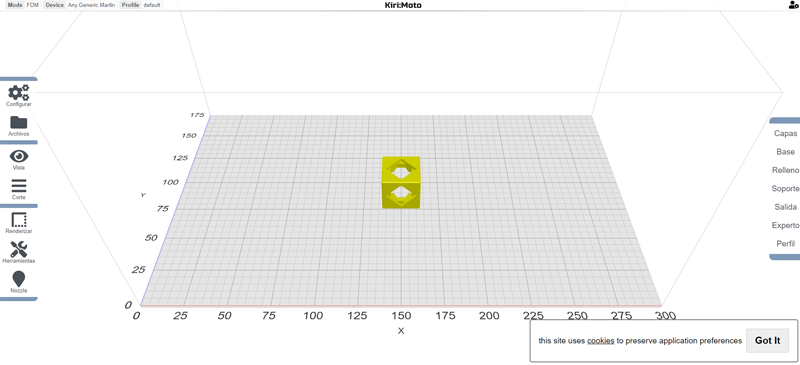

Kiri:Moto

One of the drawbacks that many users often encounter is the limited capacity to process heavy software on their computer. Like SlicerCrafter, Kiri:Moto is a cloud-based programme that runs online and has a very neat interface.

Image 5: Kiri:Moto interface. Source: Kiri:Moto

This FDM 3D printer laminator can also generate codes for SLA, CNC machining and laser engraving. Kiri:Moto has preset dimensions, speeds, GCode and process-specific settings. If the specific parameters for the 3D printer to be used are not available in the library, they can be specifically programmed.

Laminating software is an indispensable tool for 3D printing. The laminator is responsible for converting the 3D model into a file that gives instructions to the 3D printer, so correct lamination directly affects the print quality. Therefore, it is important to choose a quality lamination software depending on the user's experience and the parameters to be modified.