Lubrication is to reduce friction and wear between one or both surfaces by interposing a lubricating substance between them.

In the FDM 3D print the correct lubrication of the moving parts of the 3D printer is critical because it can directly affect the final quality of the printed pieces. If the rods or bearings are poorly lubricated 3D printer, the print carriage may tend to move to blows and generate an annoying noise. In this way you lose accuracy in positioning the print head.

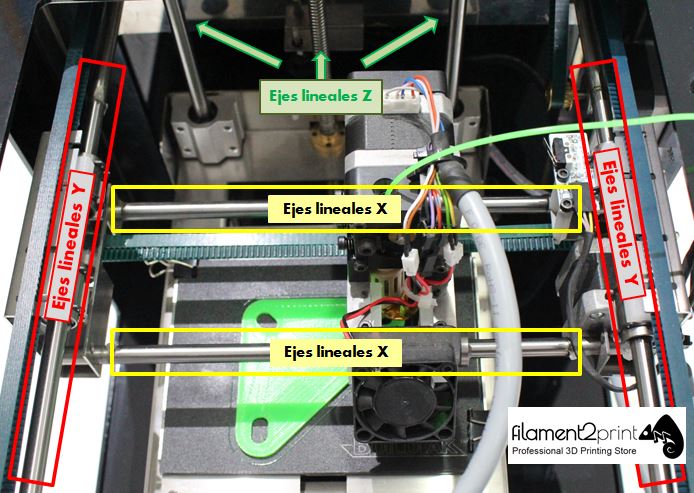

The main parts of a FDM 3D printer to be lubricated are threaded rods and bearings (roller bearings and linear bearings).

In order to select a good lubricant must be identified before the type of movement, speed, temperature, load and operating environment. Oils and fats are used as lubricants in 3D printing, although the main advantages of fats against oils besides not leak are to have a greater ability to form a lubricating film that reduces friction and wear due to contact metal-metal, increased corrosion protection, sealing properties that prevent entry of contaminants, greater resistance to structural or consistency changes (tenacity) can operate under extreme conditions, and finally have a greater resistance to deterioration caused by high temperatures.

By definition, a grease is a semifluid material formed by a thickening agent (65-95 %) a base (5-35 %) oil and usually a number of additives (0-10 %) as antioxidants and corrosion inhibitors.

The main properties of a lubricating grease are:

- Consistency. Fat firmness. It is measured by the NLGI (National Lubricant Grease Institute)

- Fluidity. Ability to be pumped.

- Mechanical stability. As the change of consistency due to use.

- Dropping Point. Temperature at which it becomes liquid.

- Extreme pressure. Ability to withstand heavy loads.

- Oxidative stability. Resistance to deterioration due to high temperatures.

- Corrosion resistance. Ability to form a protective film against oxidation.

- Resistance to water washout.

- Separation of oil. Ability to maintain its lubricating properties and consistency.

All these parameters are more or less very important in relation to the lubrication of the moving parts of the 3D FDM printers. Today you exist greases recommended for use in 3D printing such as Superlube or Magnalube. The SuperLube synthetic NLGI Grade 2 and with Syncolon (PTFE) is a high quality lubricant that provides protection against friction, wear, rust and corrosion. The working range of the same ranges from -43 °C to 232 °C. With this grease the moving parts of the 3D printer last longer and increase productivity.

3D printers with hot base is recommended to use the lubricant Superlube or Magnalube every 75 - 100 hours of use for those moving parts that directly receive heat from the base. 3D printers that do not have hot base, or parts not exposed to heat radiation from the base, is recommended to use lubricant every 200 to 250 hours of use. It is also important to apply grease Superlube on a dry surface, clean grease fittings before applying grease to prevent contamination and do not use this fat on a different fat.

What is the best lubricate for a Acorn Chair lift?

I have found PlanetSafe AIM to work much better than SuperLube or Magnalube - those both gummed up my slide rails. Planetsafe AIM lubricant worked like a charm. They sell it on Amazon.