Some people still think that only decorative objects, toys and non-functional prototypes can be 3D printed using FDM technology. However, thanks to the research and development of 3D printing materials, there are now a multitude of advanced filaments with specific properties or improved mechanical properties.

Whether the user wants to produce final parts, functional prototypes or simply professionally finished models, FDM 3D printing may be the right manufacturing technology.

Addnorth, a renowned Swedish filament manufacturer, was founded in 2016 in response to the lack of filament producers in the Nordic countries and the difficulty in finding technical materials for FDM 3D printing in the region. Addnorth now has an extensive range of materials, including materials developed for engineering applications, such as Adura X filament.

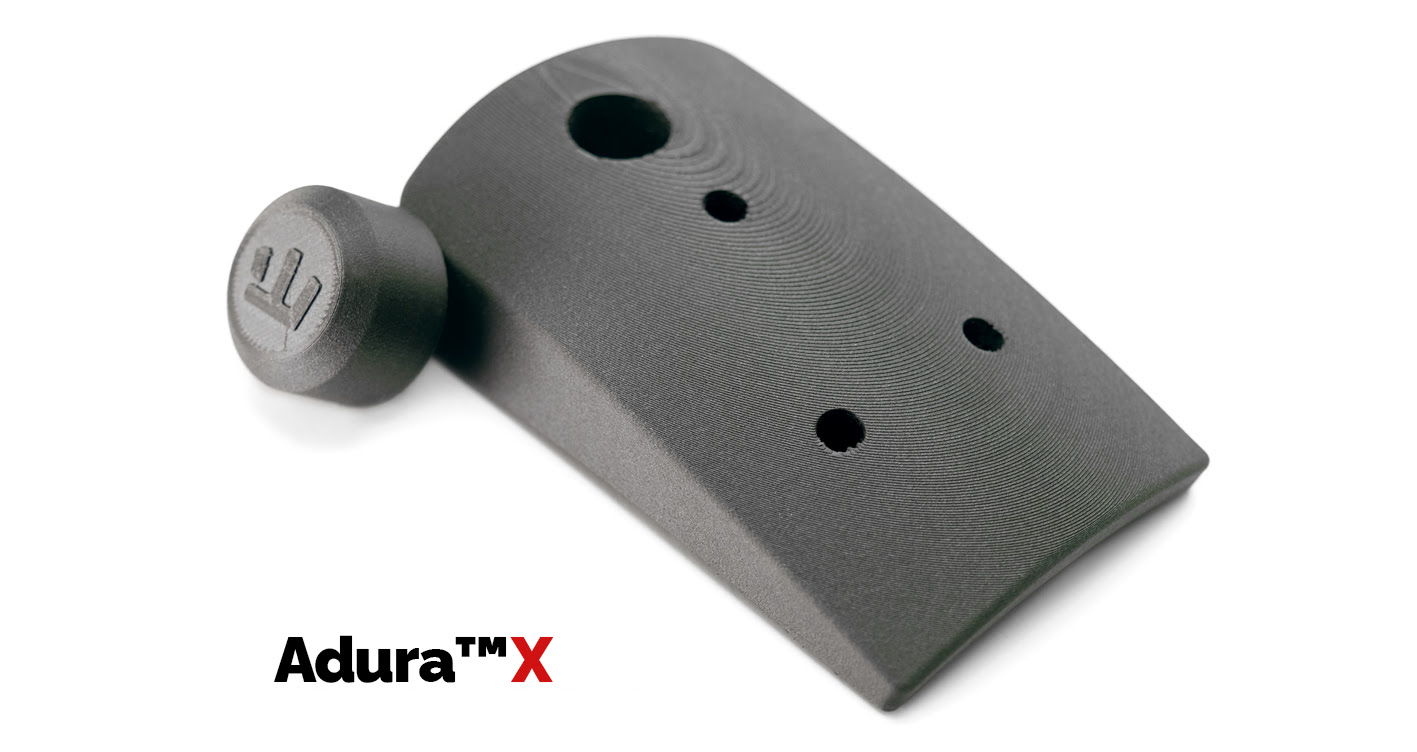

Adura X is a nylon-based, carbon fibre-filled filament developed for the manufacture of tough parts for high performance environments.

RGNT-Motorcycles, a manufacturer of high-tech electric motorbikes with café racer styling, has chosen this material for the manufacture of various end parts that are included in their motorbikes.

Video 1: RGNT-Motorcycles. Source: Addnorth.

RGNT-Motorcycles takes care of every detail of its motorbikes, from the first sketches to the final assembly, aiming to offer the customer motorbikes with a timeless design and style fused with the most advanced technology.

RGNT-Motorcycles finds in FDM 3D printing the possibility to manufacture its own parts quickly, effectively and affordably, being able to obtain prototypes or final parts in a matter of hours.

Image 1: Parts 3D printed with Adura X by RGNT. Source: Addnorth.

They say there are a multitude of applications where FDM 3D printing can be used, from internal parts that are not visible to the naked eye but create added value by attaching cables or sensors, to external parts that hold or position other elements in place.

The material used, Adura X, meets all mechanical and appearance requirements:

- Thanks to its carbon fibre filler, the surface finish is a matte black colour that is very attractive for final parts, as it helps to hide the lines corresponding to the layers produced in FDM 3D printing manufacturing.

- In terms of properties, Adura X retains certain properties of Nylon, such as good flexibility, chemical and thermal resistance. In addition, thanks to the carbon fibre filler, the material is stiffer and has improved dimensional stability and impact resistance.

As with RGNT-Motorcycles and Adura X filament, there are a multitude of materials with advanced properties that are perfect for a variety of applications in industries such as engineering. In addition, in many cases, these materials do not require the use of industrial 3D printers, making them a fast and affordable method of manufacture.