No products

Product successfully added to your cart

0 products in the cart 1 product in the cart

E3D

E3D-Online is a manufacturer of high quality FDM 3D printer components specialized in extruders, HotEnd and nozzles. The key to its success is the relationship of quality and price offered by its products and the ease of adapting to each 3D printer.

-

E3D bowden connector clip E3D bowden connector clip

0,17 € tax excl.

0,17 € tax incl.Original E3D replacement connector clip for attaching PTFE tubing. Original E3D replacement connector clip for attaching PTFE tubing.

-

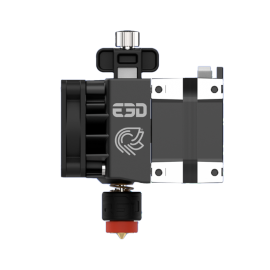

E3D Hemera E3D Hemera

123,55 € tax excl.

123,55 € tax incl.The most advanced E3D extrusion system, with "dual-drive" technology. The most advanced E3D extrusion system, with "dual-drive" technology.

-

E3D Hemera Heat Break E3D Hemera Heat Break

10,95 € tax excl.

10,95 € tax incl.1.75 mm heat break for V6, Volcano and Super Volcano heater blocks. 1.75 mm heat break for V6, Volcano and Super Volcano heater blocks.

-

E3D Hemera XS Bowden V2 E3D Hemera XS Bowden V2

209,95 € tax excl.

209,95 € tax incl.Compact and light Hemera extruder optimized for short Bowden setups. Compact and light Hemera extruder optimized for short Bowden setups.

-

E3D Original Cartridge Thermistor E3D Original Cartridge Thermistor

9,45 € tax excl.

9,45 € tax incl.Cartridge thermistor specially manufactured for E3D. Cartridge thermistor specially manufactured for E3D.

-

E3D Original Copper Heater Block E3D Original Copper Heater Block

32,95 € tax excl.

32,95 € tax incl.Original nickel plated copper heater block for the V6 and Volcano hotends. Original nickel plated copper heater block for the V6 and Volcano hotends.

-

E3D Original Heat Break E3D Original Heat Break

16,90 € tax excl.

16,90 € tax incl.Heat Break (barrel) with HotEnd v6 1.75mm and 3mm. Heat Break (barrel) with HotEnd v6 1.75mm and 3mm.

-

E3D Original Heater Block E3D Original Heater Block

14,95 € tax excl.

14,95 € tax incl.The heater block most used in the world of 3D printing. The heater block most used in the world of 3D printing.

-

E3D Original Heater Cartridge E3D Original Heater Cartridge

12,95 € tax excl.

12,95 € tax incl.High performance and high durability, recommended for high printing temperatures. High performance and high durability, recommended for high printing temperatures.

-

E3D Original V6 Heatsink E3D Original V6 Heatsink

17,90 € tax excl.

17,90 € tax incl.Key element of the Original E3D hotend v6 for proper filament extrusion. Key element of the Original E3D hotend v6 for proper filament extrusion.

-

E3D Revo Hemera XS Extruder E3D Revo Hemera XS Extruder

209,08 € tax excl.

209,08 € tax incl.Compact dual-drive extrusion system compatible with the Revo and V6 systems. Compact dual-drive extrusion system compatible with the Revo and V6 systems.

-

E3D Revo HT 65 W Heater Cartridge E3D Revo HT 65 W Heater Cartridge

68,90 € tax excl.

68,90 € tax incl.Heater cartridge for high temperature 3D printing. Reduced heat-up time and increased longevity. Heater cartridge for high temperature 3D printing. Reduced heat-up time and increased longevity.

-

E3D Revo HT Heater Block E3D Revo HT Heater Block

45,89 € tax excl.

45,89 € tax incl.Nickel plated copper heater block for high temperature 3D printing. Nickel plated copper heater block for high temperature 3D printing.

-

E3D Revo Roto extruder E3D Revo Roto extruder

133,83 € tax excl.

133,83 € tax incl.Light and compact extruder with 70 N+ extrusion force. High compatibility with E3D ecosystem. Light and compact extruder with 70 N+ extrusion force. High compatibility with E3D ecosystem.

-

E3D SuperVolcano Original Heater Cartridge E3D SuperVolcano Original Heater Cartridge

19,95 € tax excl.

19,95 € tax incl.Developed specifically for use with the E3D SuperVolcano heater block. Developed specifically for use with the E3D SuperVolcano heater block.

-

E3D SuperVolcano Upgrade Kit E3D SuperVolcano Upgrade Kit

123,95 € tax excl.

123,95 € tax incl.Special HotEnd developed for fast, large 3D prints. Special HotEnd developed for fast, large 3D prints.

-

Ferrules for joining wires (Pack of 10) Ferrules for joining wires (Pack of 10)

1,95 € tax excl.

1,95 € tax incl.It allows to realize fast junctions resistant to high temperatures, especially for thermistors. It allows to realize fast junctions resistant to high temperatures, especially for thermistors.

-

Hotend High Flow ObXidian for Bambu Lab X1/P1 Series Hotend High Flow ObXidian for Bambu Lab X1/P1 Series

92,52 € tax excl.

92,52 € tax incl.Compact and light high flow E3D hotend for the Bambu Lab 3D printers. Compact and light high flow E3D hotend for the Bambu Lab 3D printers.

-

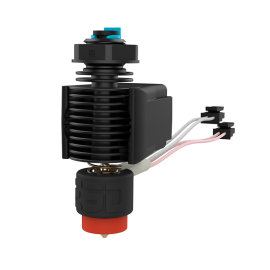

Hotend Revo Micro Hotend Revo Micro

112,95 € tax excl.

112,95 € tax incl.Small and light hotend of the E3D Revo range that allows to achieve higher printing speed. Small and light hotend of the E3D Revo range that allows to achieve higher printing speed.

-

Hotend Revo Prusa Edition Hotend Revo Prusa Edition

89,95 € tax excl.

89,95 € tax incl.Original E3D Revo drop-in replacement hotends for the Prusa Mini and Prusa MK3 hotends. Original E3D Revo drop-in replacement hotends for the Prusa Mini and Prusa MK3 hotends.

-

Hotend Revo Six Hotend Revo Six

82,64 € tax excl.

82,64 € tax incl.Original E3D Hotend with Revo system for direct replacement of the E3D Hotend V6. Original E3D Hotend with Revo system for direct replacement of the E3D Hotend V6.

-

Nozzle Revo E3D Nozzle Revo E3D

29,95 € tax excl.

29,95 € tax incl.Original E3D nozzles with Rapid Change system compatible with Revo hotends. Original E3D nozzles with Rapid Change system compatible with Revo hotends.

-

Nozzle Revo High Flow E3D Nozzle Revo High Flow E3D

44,95 € tax excl.

44,95 € tax incl.REVO nozzles that enable high volumetric flow rates and faster 3D printing. REVO nozzles that enable high volumetric flow rates and faster 3D printing.

-

Nozzle Revo HT-Abrasive (high temperature) E3D Nozzle Revo HT-Abrasive (high temperature) E3D

62,23 € tax excl.

62,23 € tax incl.Abrasion resistant REVO nozzles for printing at temperatures of up to 500 ºC. Abrasion resistant REVO nozzles for printing at temperatures of up to 500 ºC.

-

Nozzle Revo ObXidian Nozzle Revo ObXidian

59,95 € tax excl.

59,95 € tax incl.Abrasion resistant copper and hardened steel Revo nozzle with E3DLC non-stick coating. Abrasion resistant copper and hardened steel Revo nozzle with E3DLC non-stick coating.

-

Nozzle X v6/Volcano E3D Original Nozzle X v6/Volcano E3D Original

38,45 € tax excl.

38,45 € tax incl.It allows to print any advanced material, supporting very high extrusion temperatures. It allows to print any advanced material, supporting very high extrusion temperatures.

-

Original E3D Extruder Titan Aero Original E3D Extruder Titan Aero

149,50 € tax excl.

149,50 € tax incl.Compact and robust extruder with advanced technology from original E3D. Compact and robust extruder with advanced technology from original E3D.

-

Original E3D high temperature heater cartridge Original E3D high temperature heater cartridge

89,95 € tax excl.

89,95 € tax incl.High-temperature heater cartridges capable of operating at up to 550 °C for extended periods of time High-temperature heater cartridges capable of operating at up to 550 °C for extended periods of time

-

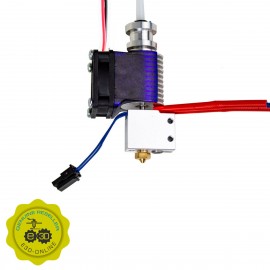

Original E3D HotEnd v6 Original E3D HotEnd v6

65,90 € tax excl.

65,90 € tax incl.Original E3D hotend with high printig temperature up to 285 ˚C. Original E3D hotend with high printig temperature up to 285 ˚C.

-

Original E3D HotEnd Volcano Original E3D HotEnd Volcano

69,90 € tax excl.

69,90 € tax incl.Original E3D Hotend perfect for increasing print speed. Original E3D Hotend perfect for increasing print speed.

-

Original E3D Nozzle for Prusa MK4/XL Original E3D Nozzle for Prusa MK4/XL

30,95 € tax excl.

30,95 € tax incl.Original nozzle with an all-metal filament guide. Only for the Prusa MK4 and XL 3D printers. Original nozzle with an all-metal filament guide. Only for the Prusa MK4 and XL 3D printers.

-

Original E3D Nozzle v6 Stainless Steel Original E3D Nozzle v6 Stainless Steel

23,90 € tax excl.

23,90 € tax incl.Nozzle for the version of the original E3D HotEnd v6, specially for food and medical applications. Nozzle for the version of the original E3D HotEnd v6, specially for food and medical applications.

-

Original E3D Nozzle v6/Volcano/SuperVolcano Brass Original E3D Nozzle v6/Volcano/SuperVolcano Brass

9,95 € tax excl.

9,95 € tax incl.Nozzle for the original HotEnd v6, Volcano and SuperVolcano versions of E3D. Nozzle for the original HotEnd v6, Volcano and SuperVolcano versions of E3D.

-

Original E3D Nozzle v6/Volcano/Supervolcano Copper Original E3D Nozzle v6/Volcano/Supervolcano Copper

16,90 € tax excl.

16,90 € tax incl.E3D Original nickel plated copper nozzles for the v6/Volcano/Supervolcano heater blocks. E3D Original nickel plated copper nozzles for the v6/Volcano/Supervolcano heater blocks.

-

Original E3D Nozzle v6/Volcano/Supervolcano Hardened Steel Original E3D Nozzle v6/Volcano/Supervolcano Hardened Steel

22,90 € tax excl.

22,90 € tax incl.Nozzle for the original HotEnd v6 and Volcano versions of E3D for filaments with fibers. Nozzle for the original HotEnd v6 and Volcano versions of E3D for filaments with fibers.

-

Original E3D ObXidian Nozzle for Prusa MK4/XL Original E3D ObXidian Nozzle for Prusa MK4/XL

48,95 € tax excl.

48,95 € tax incl.Easy to change nozzle with extreme wear resistance. Only for the Prusa MK4 and XL 3D printers. Easy to change nozzle with extreme wear resistance. Only for the Prusa MK4 and XL 3D printers.

-

Original E3D Titan Extruder Original E3D Titan Extruder

98,35 € tax excl.

98,35 € tax incl.Original E3D extruder optimized for all types of filaments and compatible with HotEnd E3D. Original E3D extruder optimized for all types of filaments and compatible with HotEnd E3D.

-

Original Nozzle Fun Pack E3D Original Nozzle Fun Pack E3D

40,95 € tax excl.

40,95 € tax incl.Original E3D pack of nozzles of different materials for the HotEnd E3D v6. Original E3D pack of nozzles of different materials for the HotEnd E3D v6.

-

Original silicone sock for Heater Block E3D Original silicone sock for Heater Block E3D

1,95 € tax excl.

1,95 € tax incl.Silicone case to keep clean and prevent deterioration of the E3D v6 and Volcano Original HeatBreak. Silicone case to keep clean and prevent deterioration of the E3D v6 and Volcano Original HeatBreak.

-

Original spanner E3D for nozzle Original spanner E3D for nozzle

1,65 € tax excl.

1,65 € tax incl.7mm wrench for mounting and unmounting the E3D nozzle. 7mm wrench for mounting and unmounting the E3D nozzle.

-

Original Upgrade kit E3D Titan Aero Original Upgrade kit E3D Titan Aero

53,95 € tax excl.

53,95 € tax incl.Kit that updates the original E3D Titan Extruder on the Titan Aero. Kit that updates the original E3D Titan Extruder on the Titan Aero.

-

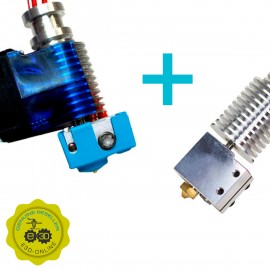

Original V6 & Volcano Power Pack E3D Original V6 & Volcano Power Pack E3D

114,95 € tax excl.

114,95 € tax incl.Full Kit with the combination of the E3D v6 and the original Volcano E3D. Full Kit with the combination of the E3D v6 and the original Volcano E3D.

-

Original Volcano E3D HotEnd (Eruption pack) Original Volcano E3D HotEnd (Eruption pack)

48,45 € tax excl.

48,45 € tax incl.Special HotEnd for fast and accurate 3D printing. Special HotEnd for fast and accurate 3D printing.

-

PT100 Upgrade Kit PT100 Upgrade Kit

44,95 € tax excl.

44,95 € tax incl.Increase printing temperature to 400°C with a much more accurate reading for all HotEnd v6 de E3D. Increase printing temperature to 400°C with a much more accurate reading for all HotEnd v6 de E3D.

-

Revo CR Revo CR

89,95 € tax excl.

89,95 € tax incl.Revo CR hotend compatible with the Creality 3D printers. Revo CR hotend compatible with the Creality 3D printers.

-

Revo HeaterCore Revo HeaterCore

44,62 € tax excl.

44,62 € tax incl.E3D heater block, heater cartridge and thermistor compatible with Revo system hotends. E3D heater block, heater cartridge and thermistor compatible with Revo system hotends.

-

Revo High Flow hotside E3D Revo High Flow hotside E3D

89,95 € tax excl.

89,95 € tax incl.Revo High Flow enables faster printing speeds by increasing the volumetric flow rate. Revo High Flow enables faster printing speeds by increasing the volumetric flow rate.

-

Revo HT hotsides E3D Revo HT hotsides E3D

176,84 € tax excl.

176,84 € tax incl.Revo High Temperature hotsides for printing at up to 500 ºC with abrasive materials. Revo High Temperature hotsides for printing at up to 500 ºC with abrasive materials.

-

Revo nozzle housings Revo nozzle housings

7,95 € tax excl.

7,95 € tax incl.Pack of original E3D protective sleeves for Revo nozzles and heater blocks. Pack of original E3D protective sleeves for Revo nozzles and heater blocks.

-

Revo Voron Revo Voron

89,95 € tax excl.

89,95 € tax incl.Original E3D Hotend with Revo system compatible with Voron printers. Original E3D Hotend with Revo system compatible with Voron printers.

-

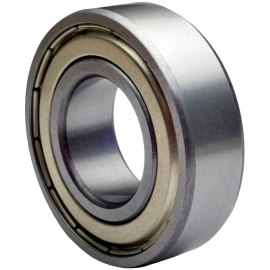

Roller bearing Roller bearing

0,98 € tax excl.

0,98 € tax incl.Bearings with metal covers to keep dirt out of the rolling elements. Bearings with metal covers to keep dirt out of the rolling elements.

-

SuperVolcano E3D Original Heater Block SuperVolcano E3D Original Heater Block

74,37 € tax excl.

74,37 € tax incl.Fiberglass heating block and protective cover for the Hotend SuperVolcano. Fiberglass heating block and protective cover for the Hotend SuperVolcano.

E3D-Online: Quality and experience

In 2012 the founders of E3D acquired one of the first Mendel 3D printers on the market. Soon, they observed that the HotEnd of this printer needed a modification and this is how the first E3D HotEnd was born: the E3D-v4. A couple of years later and thanks to the success of the E3D HotEnds, the HotEnd v6, is born, a HotEnd with an improved design, manufactured in great detail and more compact than its predecessor. From this point on, E3D-Online has developed a range of 3D printing products that are leaders in sales and always one step ahead of their competitors. These products include standard and highly specialized nozzles, the classic hotends v6, Volcano and SuperVolcano, the classic extruders Hemera or Titan, the famous Rapid Change Revo hotends and extruders, products designed to provide high flow or high temperature performance, or components designed specifically for the users of printers by brands such as Creality, Prusa or Bambu Lab.

Products that adapt to each print

E3D-Online has always stood out for solving problems that arise from the development and evolution of 3D FDM printing. Its range includes nozzles of all types: brass for printing with conventional filaments, hardened steel for abrasive filaments, stainless steel for filaments that are in contact with food and steel for filaments that need high extrusion temperatures. Apart from those nozzle collections, E3D develops nozzles for high flow applications or for specific 3D printer brands in order to satisfy the needs of each and every 3D printer user. Most of these nozzles are available in different output diameters and in version v6 and Volcano/SuperVolcano.

Components for industrial prints

Due to the evolution of 3D FDM printing with the development of industrial and advanced materials, this manufacturer has developed components for 3D printers capable of using these filaments. The Nozzle X is a nozzle made of a tool steel for the manufacture of utensils that are constantly exposed to friction and shock. To complement the hardness of tool steel, nickel plating has been added to all nozzle walls. These properties allow printing advanced materials (450 °C extruder) with fiber, such as PEKK-Carbon Fiber or PEI-Carbon Fiber, without problems of wear or jams.