No products

Product successfully added to your cart

0 products in the cart 1 product in the cart

View larger

View larger

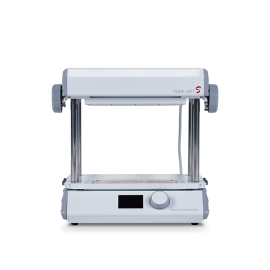

Do you want to have the ability to produce filament on demand, the one you need in the right color and size for your 3D project?

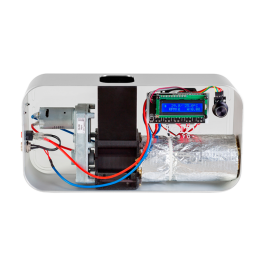

The Filastruder by the brand Filastruder meets those needs and more, because it is a machine that allows you to filament with the specifications you choose. With Filastruder Kit you can make the filament diameter or 1.75mm 3mm, depending on the chosen extruder. The contents of each version is as follows:

- Filastruder Kit: Contains all parts included in the original kit manufactured by Tim Elmore. You need to assemble to larger 3D printed parts. In the download area you can download the STL files printed parts. In the download area you can find the guide that we indicate step by step how mount the kit. In addition, each kit includes 500g of ABS pellets.

- Assembled kit Filastruder: Original kit Filastruder fully assembled and tested its operation. In addition, each kit includes 500g of ABS pellets.

Note: The assembly kit filastruder sent may take 2 to 4 weeks.

How does Filastruder work?

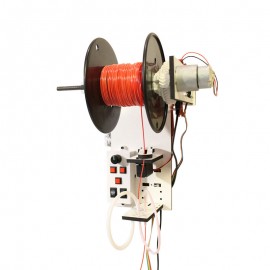

Simply must adjust the desired extrusion temperature, wait until this is achieved in the extruder and then must be added to the pellets and dyes in the hopper to your choice and start the engine gear and begin extruding the Filastuder. The filament by gravity form a roll on the floor or Security for events can also go on a reel if desired using a hand drill.

The ABS is generally the easiest to extrude material. They are achievable tolerances of up to +/- 0.02 mm. With the PLA you have to be a little more careful because you have to make sure they are free pellets moisture before extruding to obtain adequate results. Then tolerances obtained with the various materials used are as follows:

- ABS: +/- 0.02 mm

- PLA: +/- 0.03 mm

- Nylon: +/- 0.02 mm

- Polycarbonate: +/- 0.04 mm

- PET: +/- 0.05 mm

- Polypropylene: +/- 0.07 mm

Can you recycle waste of plastic parts?

If possible, although several difficulties. Should shred the pieces and debris into pieces not exceeding 5 mm on either side. You should avoid containing contaminants (dust, metal waste, etc). Furthermore it must take into account the cycle of the polymers. A more times polymer is reheated becomes weaker as each heat cycle weakens their polymer chains.For this it is essential to add to the waste pellets of virgin material to maintain the ideal strength.

There is a community of users around the world Filastruder interacting with each other, resolving all doubts in the following forum.